CHECKING AND ADJUSTING TABLE ROLLER HEIGHT

It is not possible to give exact dimensions on the prop- er height setting of the table rollers because each type of wood has different behavioral patterns. As a general rule, when planing rough stock, the table rollers should be set high (.003 to .005 ) above the table surface.

When planing finish stock, the table rollers should be set low (.001 ) above or level with the table surface.

To check and adjust the height of the table rollers, pro- ceed as follows:

1. |

|

|

| DISCONNECT THE MACHINE FROM |

|

|

| ||

|

|

| ||

|

|

|

| THE POWER SOURCE. |

|

|

|

|

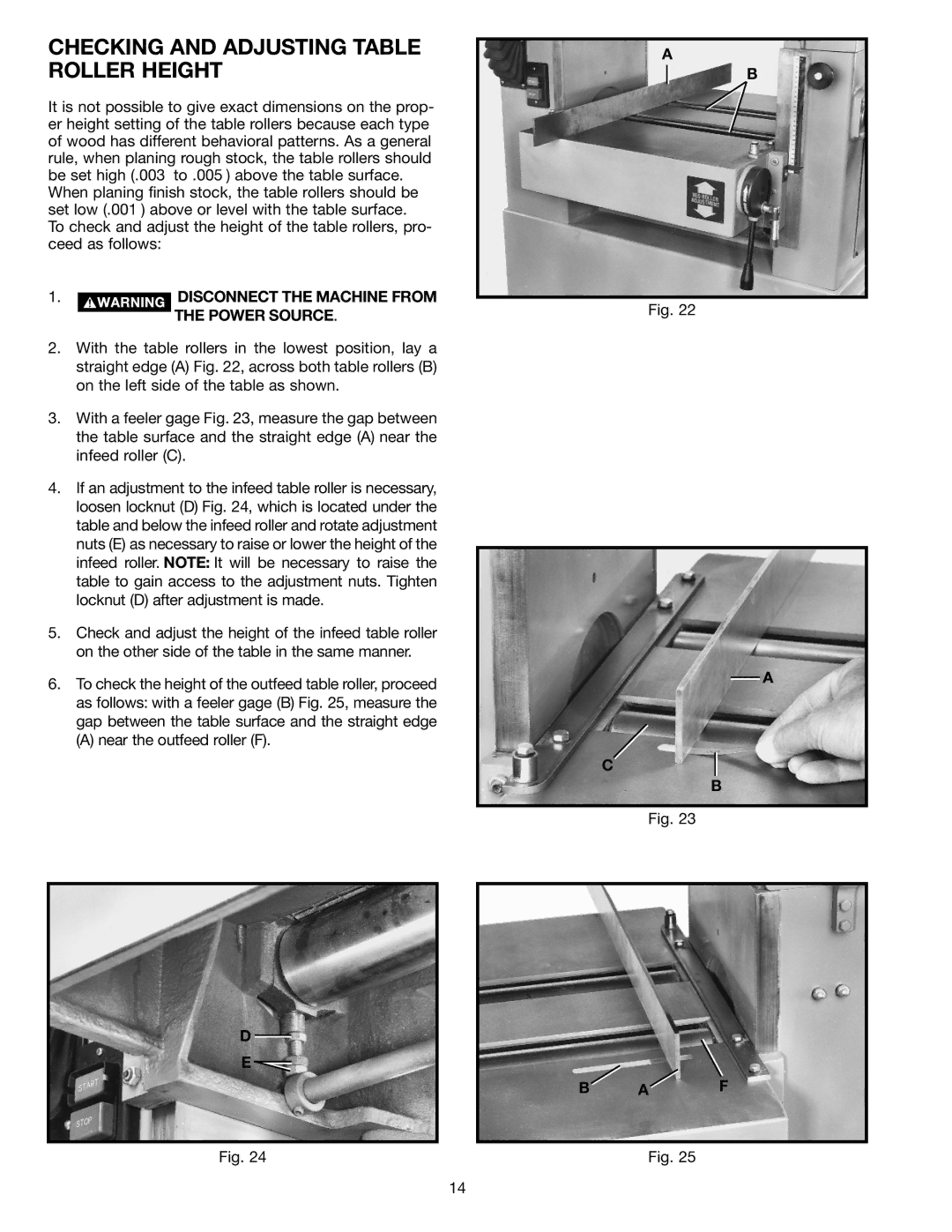

2.With the table rollers in the lowest position, lay a straight edge (A) Fig. 22, across both table rollers (B) on the left side of the table as shown.

3.With a feeler gage Fig. 23, measure the gap between the table surface and the straight edge (A) near the infeed roller (C).

4.If an adjustment to the infeed table roller is necessary, loosen locknut (D) Fig. 24, which is located under the table and below the infeed roller and rotate adjustment nuts (E) as necessary to raise or lower the height of the infeed roller. NOTE: It will be necessary to raise the table to gain access to the adjustment nuts. Tighten locknut (D) after adjustment is made.

5.Check and adjust the height of the infeed table roller on the other side of the table in the same manner.

6.To check the height of the outfeed table roller, proceed as follows: with a feeler gage (B) Fig. 25, measure the gap between the table surface and the straight edge

(A) near the outfeed roller (F).

D

E![]()

Fig. 24

A

B

Fig. 22

A

C![]()

B

Fig. 23

BA ![]() F

F

Fig. 25

14