Thank you for purchasing this projector

About this manual

Projector

Trademark acknowledgment

Contents

Features

Checking the contents of package

Grip

Part names

Projector

Only for 8971, 8973W and 8975WU

Lens Shift button &29

Ports &10 ~

Computer IN1 port

Magnify on / OFF buttons 35

Part names

Digital button

UP / page Down buttons 19

Setting up

Arrangement

Arrangement

Arrangement

Connecting with your devices

About Plug-and-Play capability

Connecting with your devices

26, 107 &26 &55 &26 Computer

USB

Computer External Device Access point

Wireless

Adapter

VCR/DVD

Blu-ray Disc TM

Player

Monitor

Another projector Wired Remote control

Fastening the cables

Tie holder

Using the security bar and slot

Connecting to a power supply

Remote control

Installing the batteries

Using the Remote ID function

AV Mute and Zoom buttons

Changing the frequency of remote control signal

About the remote control signal

F5 and Keystone buttons

Using as a simple PC mouse & keyboard

USB Type B port

Only for 8971, 8973W and 8975WU

Status Monitor

Displaying the condition of the projector

In a normal state

In error state

Displaying the condition of the projector

3rd line

Function

To display the setup information including usage time

Displaying the log

Enter

To display error history

Displaying the log

Power on/off

Turning on the power

Turning off the power

Temporarily turning off the screen and audio

Adjusting the volume

Operating

VOL +

Button Ports

Selecting an input signal

Input button

Video

Selecting an aspect ratio

Holding the projector, push the elevator buttons to

Adjusting the lens position

Adjusting the lens

Adjusting the zoom and focus

Lens Shift button Zoom + / buttons Focus + / buttons

Position button

Adjusting the lens

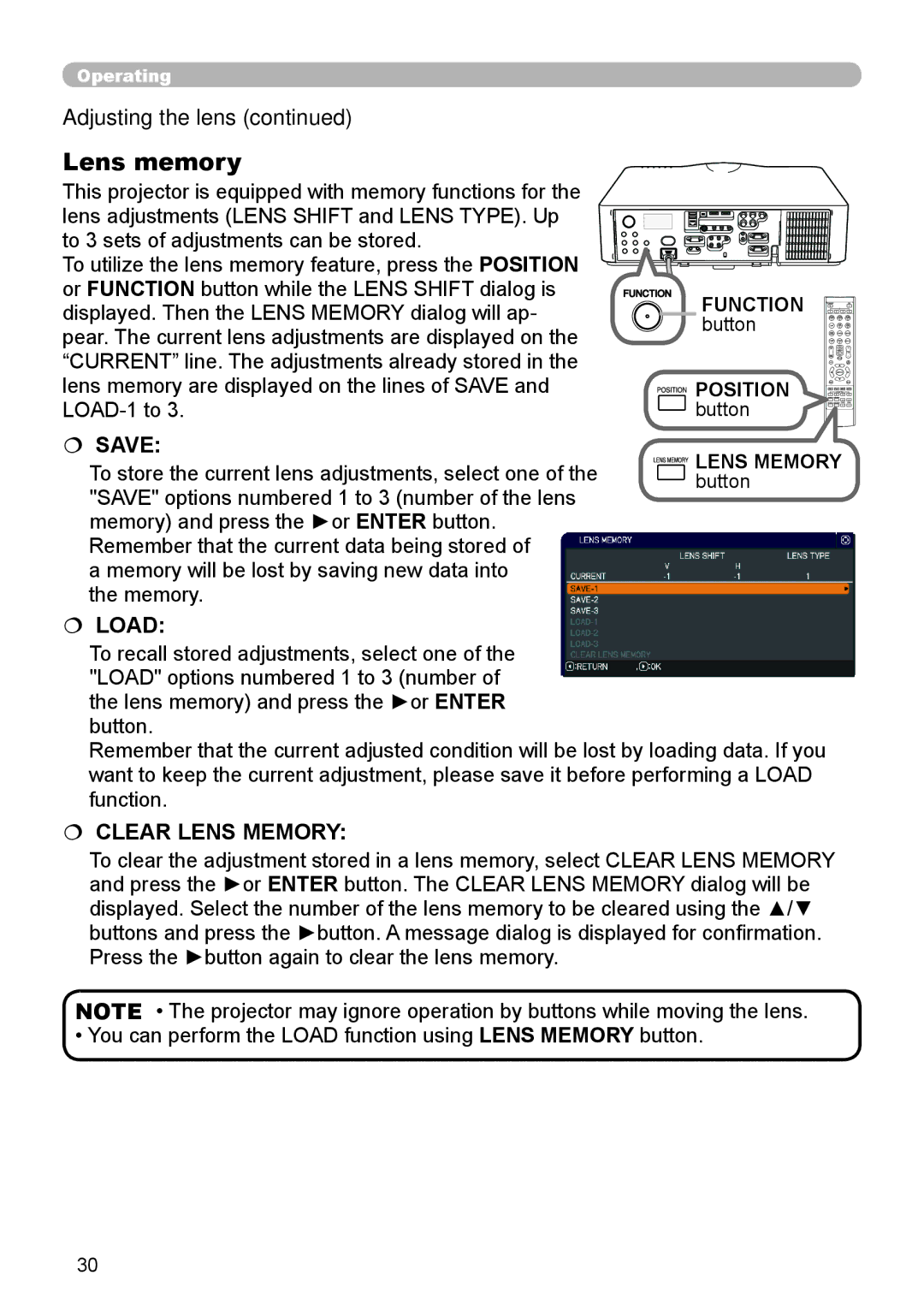

Lens memory

Lens Memory button

For a computer signal

Using the automatic adjustment feature

Adjusting the position

For a video signal and s-video signal

Correcting the distortion

Keystone

Correcting the distortion

8970 8972W, 8973W 8976SX, 8974WU, 8975WU

Only for 8970, 871, 8972W and 8973W

Enter or Input button

Using the magnify feature

Magnify on / OFF buttons

Temporarily freezing the screen

Temporarily shading the screen

Shade button

Advanced Menu

Using the menu function

Easy Menu

Input

Using the menu function

Indication in OSD On Screen Display

Indication Meaning

Containing items of each menu

Auto Keystone

Picture Mode

Description

Perfect FIT

Reset

ECO Mode

Installation

Filter Time

Contrast

Picture menu

Brightness

Gamma

Color Temp

Color

Tint

Sharpness

Active Iris

8972W, 8973W, 8976SX, 8974WU, 8975WU

For a computer signal 8970

Image menu

8976SX

Over Scan

Or Hdmi 1 / 2 port

Size

Phase

Auto Adjust

Execute

Video NR

Input menu

Progressive

Color Space

Auto ó Video ó Computer

Video Format

Hdmi Format

Hdmi Range

Computer

Frame Lock

Resolution

Setup menu

See Perfect FIT in Correcting the distortion 33

Instalation

Standby Mode

Normal ó Saving

Speaker

Volume

Audio menu

Audio Source

Hdmi Audio

Blank

Screen menu

Menu Position

Start UP

Capturing error has occurred. Please try again

Description MyScreen

MyScreen registration is finished

MyScreen Lock

Message

Source Name

Template

Mode

Description Closed Caption

Display

Channel

Option menu

Auto Search

Shade Timer

Direct Power

Auto Power

OFF

8971, 8973W, 8975WU

Type B port

Lamp Time

Air filter 113

MY Button

Service

Altitude

Ghost

Filter Message

Lens Type

Lens Lock

Remote Freq

KEY Lock

Remote Receiv

Remote ID

Communication Type

Network Guide

Baud Rate

Serial Settings

Control port

Parity

Response Limit Time

Stack

Guide

Factory Reset

Information

It shows the information about the current input

Wireless

Setup

Network menu

Dhcp

Wireless Setup

Default

IP Address

Date and Time information from the Time server

Settings in the Network Guide

Date

Date/Time

Wireless Setup Ssid

Wireless Information

Wired Setup

Wired Information

Projector Name

MY Image

AMX D.D

Presentation

Quit

Presenter

Multi PC

User Name

Enter to the Security menu

Password

Security menu

Security

Turning on the MyScreen Password

Turning off the MyScreen Password

MyScreen

Turning off the PIN Lock

PIN Lock

Turning on the PIN Lock

If you have forgotten your PIN code

Detector

Transition

Turning on the Transition Detector

Turning off the Transition Detector

Turning on the MY Text Password

MY Text Password

Turning off the MY Text Password

MY Text

Writing

Indicator

Stack Lock

Supported storage media

Presentation tools

PC-LESS Presentation

Supported format

Thumbnail Mode

PC-LESS Presentation

Button operation

Setup menu for the selected image

Operating by buttons

Down Enter Input

Operating by the Thumbnail menu

Interval

PC-LESS Presentation

Down

Full Screen Mode

Operations for still images

Enter Input

Operations for movie

Slideshow Mode

Operating by Slideshow in the Thumbnail menu

Playlist

Example of playlist.txt files

Saving and displaying drawn images

Drawing function

Drawing on projected images

Use as a simple mouse

Connecting the Devices

Drawing function

Example of connections

Using the Drawing function

3 4 5 6 7 8

Pen

Specifi es a 12-dot Eraser

Eraser

Previously drawn lines

Specifi es a 20-dot Eraser

Mouse

Exit

Hardware and software requirement for computer

USB Display

Other models 1280 x

Usba Port USB cable 1 piece

Starting USB Display

USB Display

Right-Click menu

Floating menu

Options window

Maintenance

Replacing the lamp

Lamp warning

Replacing the lamp

Cleaning and replacing the air filter

Only for 8971, 8972W and 8975WU

Cleaning and replacing the air filter

Inside of the projector

Caring for the cabinet and remote control

Other care

Caring for the lens

Related messages

Troubleshooting

Message Description There is no input signal

Source even if Mouse is selected for USB Type B

Related messages

An improper signal is input

Internal temperature is rising

Button operation is not available

Regarding the indicator lamps

Description

Regarding the indicator lamps

It is time to clean the air filter

Cooling fan is not operating

Air filter is going to be choked

Resetting all settings

It is recommended to clean it

Air filter is choked

Signal source does not correctly work

Electrical power cord is not plugged

Signal cables are not correctly connected

Input changeover settings are mismatched

Play monitor

Mode selected for Hdmi Audio is not suitable

Sound button or checkbox is disabled

Lens shade is closed

Projector is operating in Eco mode

Color settings are not correctly adjusted

Color Space setting is not suitable

Not properly adjusted

Same network address is set for both wireless

Frame Lock function cannot work on Current input signal

When LAN, USB Type a or USB Type B port is

Wired LAN

Disconnect the LAN cable and check that

Internal clock has been reset

Network Bridge function is turned off

Projector is working properly

Specifications