or similar tool for stirring and applying epoxy, and a paper plate or piece of cardboard to mix the epoxy on. Supplies: rubbing alcohol, 100 grit sandpaper, specially formulated epoxy adhesive available from LEI (see ordering information on the inside portion of the back cover). A sandwich hull also requires polyester resin.

Selecting a Transducer Location

1.The location must be in the water at all times, at all operating speeds.

2.The transducer must be placed in a location that has a smooth flow of water at all times. If the transducer is not placed in a smooth flow of water, interference caused by bubbles and turbulence will show on the sonar's display in the form of random lines or dots whenever the boat is moving.

NOTE:

Some aluminum boats with strakes or ribs on the outside of the hull create large amounts of turbulence at high speed. These boats typically have large outboard motors capable of propelling the boat at speeds faster than 35 mph. Typically, a good transom location on aluminum boats is between the ribs closest to the engine.

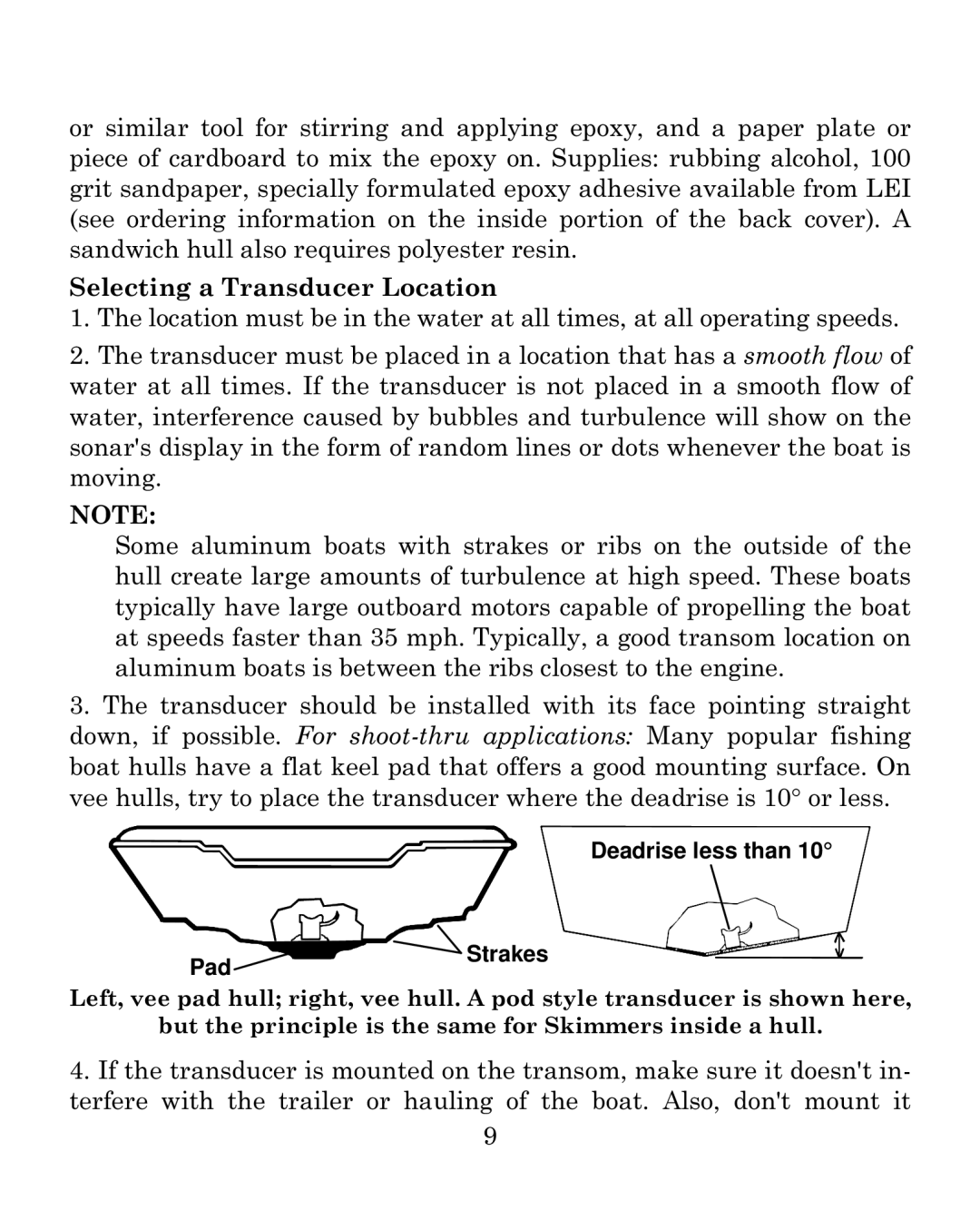

3.The transducer should be installed with its face pointing straight down, if possible. For

boat hulls have a flat keel pad that offers a good mounting surface. On vee hulls, try to place the transducer where the deadrise is 10° or less.

Pad

Deadrise less than 10°

Strakes

Strakes

Left, vee pad hull; right, vee hull. A pod style transducer is shown here,

but the principle is the same for Skimmers inside a hull.

4.If the transducer is mounted on the transom, make sure it doesn't in- terfere with the trailer or hauling of the boat. Also, don't mount it

9