SPRAYER COMPONENTS & USE INFORMATION, Continued

HELPFUL SPRAYING INFORMATION

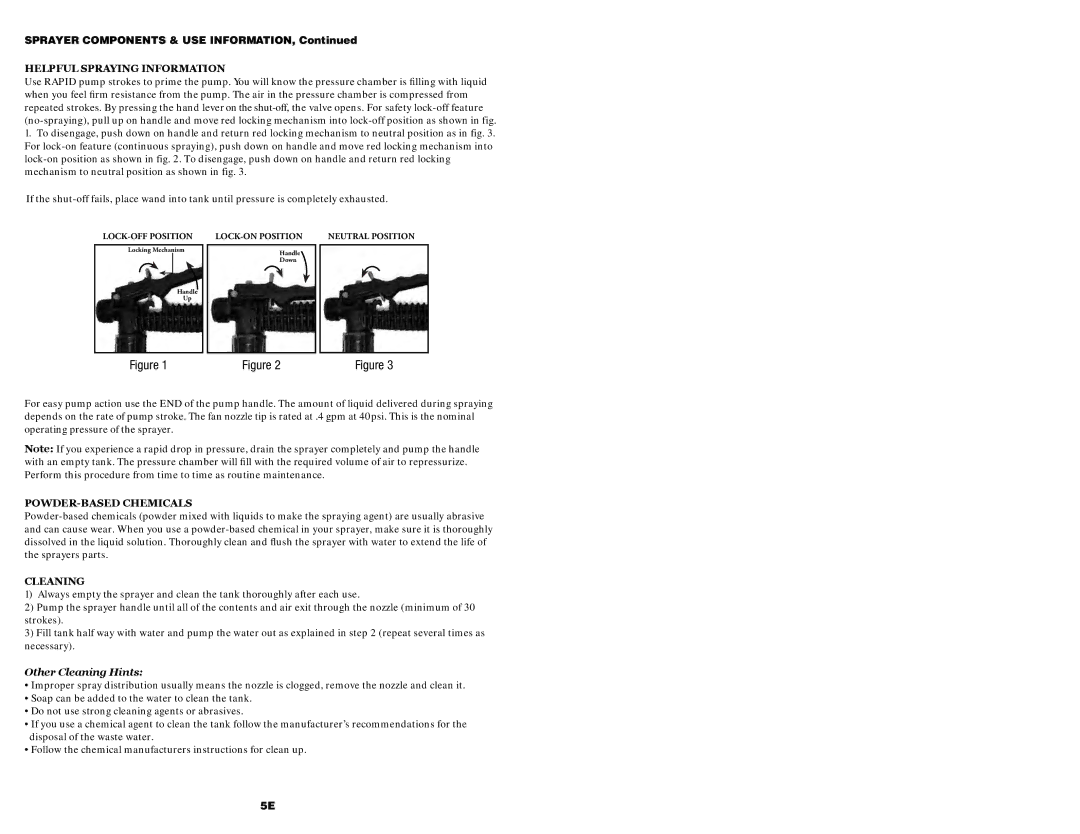

Use RAPID pump strokes to prime the pump. You will know the pressure chamber is filling with liquid when you feel firm resistance from the pump. The air in the pressure chamber is compressed from repeated strokes. By pressing the hand lever on the

1.To disengage, push down on handle and return red locking mechanism to neutral position as in fig. 3. For

If the

Locking Mechanism

Handle

Up

NEUTRAL POSITION |

Handle

Down

Figure 1 | Figure 2 | Figure 3 |

For easy pump action use the END of the pump handle. The amount of liquid delivered during spraying depends on the rate of pump stroke. The fan nozzle tip is rated at .4 gpm at 40psi. This is the nominal operating pressure of the sprayer.

Note: If you experience a rapid drop in pressure, drain the sprayer completely and pump the handle with an empty tank. The pressure chamber will fill with the required volume of air to repressurize. Perform this procedure from time to time as routine maintenance.

POWDER-BASED CHEMICALS

CLEANING

1)Always empty the sprayer and clean the tank thoroughly after each use.

2)Pump the sprayer handle until all of the contents and air exit through the nozzle (minimum of 30 strokes).

3)Fill tank half way with water and pump the water out as explained in step 2 (repeat several times as necessary).

Other Cleaning Hints:

•Improper spray distribution usually means the nozzle is clogged, remove the nozzle and clean it.

•Soap can be added to the water to clean the tank.

•Do not use strong cleaning agents or abrasives.

•If you use a chemical agent to clean the tank follow the manufacturer’s recommendations for the disposal of the waste water.

•Follow the chemical manufacturers instructions for clean up.

5E