5.CONNECTING TO GAS

This appliance is designed to be installed with an appliance flexible connection only. Supply piping should not be less than R³/8 (³/8" B.S.P.). Connection is made to the Rc½ (½" B.S.P.) female threaded entry pipe located just below the hotplate level on the rear left hand side of the appliance.

Check for gas soundness after connecting the gas supply.

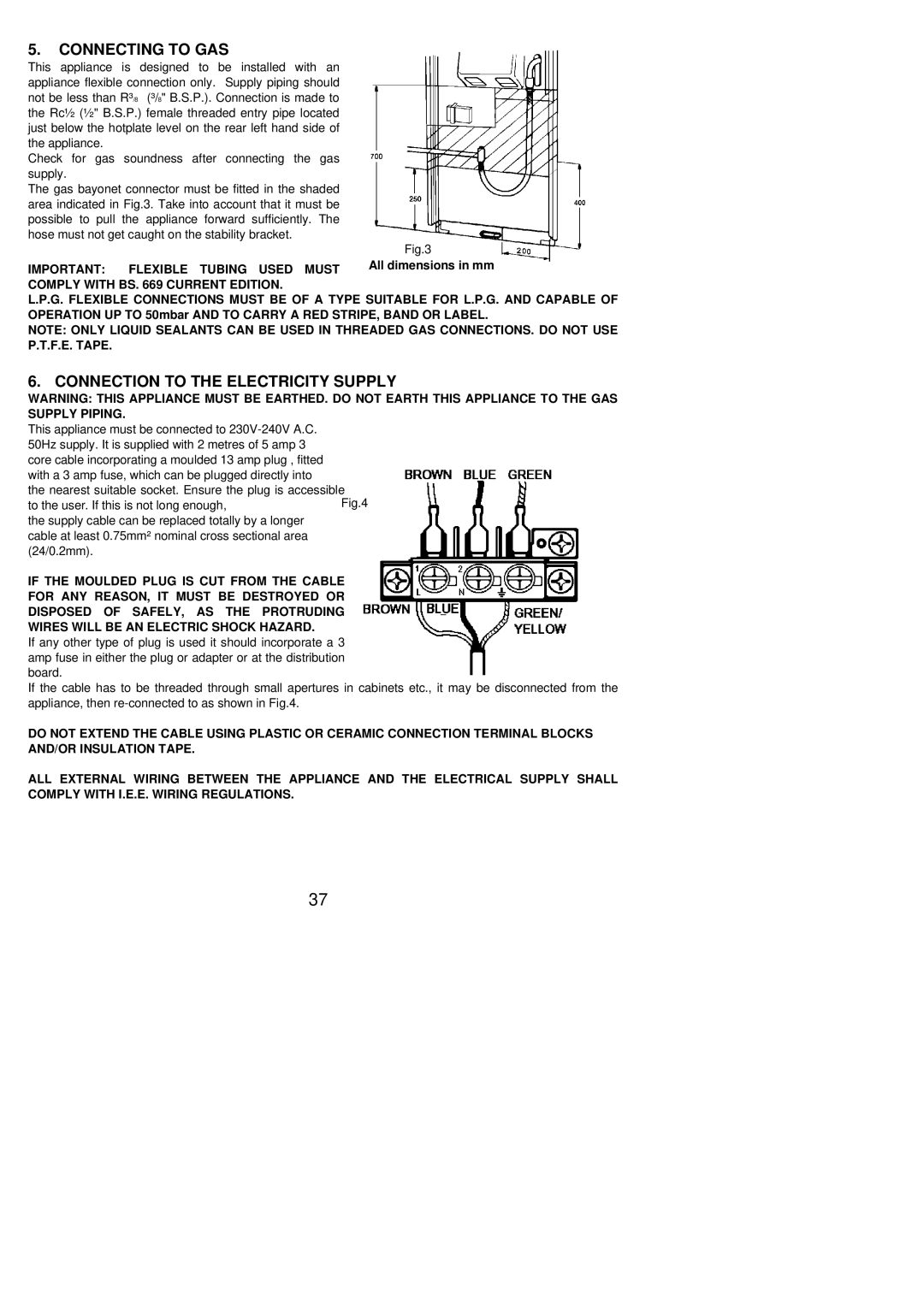

The gas bayonet connector must be fitted in the shaded area indicated in Fig.3. Take into account that it must be possible to pull the appliance forward sufficiently. The hose must not get caught on the stability bracket.

IMPORTANT: FLEXIBLE TUBING USED MUST COMPLY WITH BS. 669 CURRENT EDITION.

L.P.G. FLEXIBLE CONNECTIONS MUST BE OF A TYPE SUITABLE FOR L.P.G. AND CAPABLE OF OPERATION UP TO 50mbar AND TO CARRY A RED STRIPE, BAND OR LABEL.

NOTE: ONLY LIQUID SEALANTS CAN BE USED IN THREADED GAS CONNECTIONS. DO NOT USE P.T.F.E. TAPE.

6. CONNECTION TO THE ELECTRICITY SUPPLY

WARNING: THIS APPLIANCE MUST BE EARTHED. DO NOT EARTH THIS APPLIANCE TO THE GAS SUPPLY PIPING.

This appliance must be connected to

the nearest suitable socket. Ensure the plug is accessible

to the user. If this is not long enough,Fig.4 the supply cable can be replaced totally by a longer

cable at least 0.75mm² nominal cross sectional area (24/0.2mm).

IF THE MOULDED PLUG IS CUT FROM THE CABLE

FOR ANY REASON, IT MUST BE DESTROYED OR

DISPOSED OF SAFELY, AS THE PROTRUDING

WIRES WILL BE AN ELECTRIC SHOCK HAZARD.

If any other type of plug is used it should incorporate a 3 amp fuse in either the plug or adapter or at the distribution board.

If the cable has to be threaded through small apertures in cabinets etc., it may be disconnected from the appliance, then

DO NOT EXTEND THE CABLE USING PLASTIC OR CERAMIC CONNECTION TERMINAL BLOCKS AND/OR INSULATION TAPE.

ALL EXTERNAL WIRING BETWEEN THE APPLIANCE AND THE ELECTRICAL SUPPLY SHALL COMPLY WITH I.E.E. WIRING REGULATIONS.

37