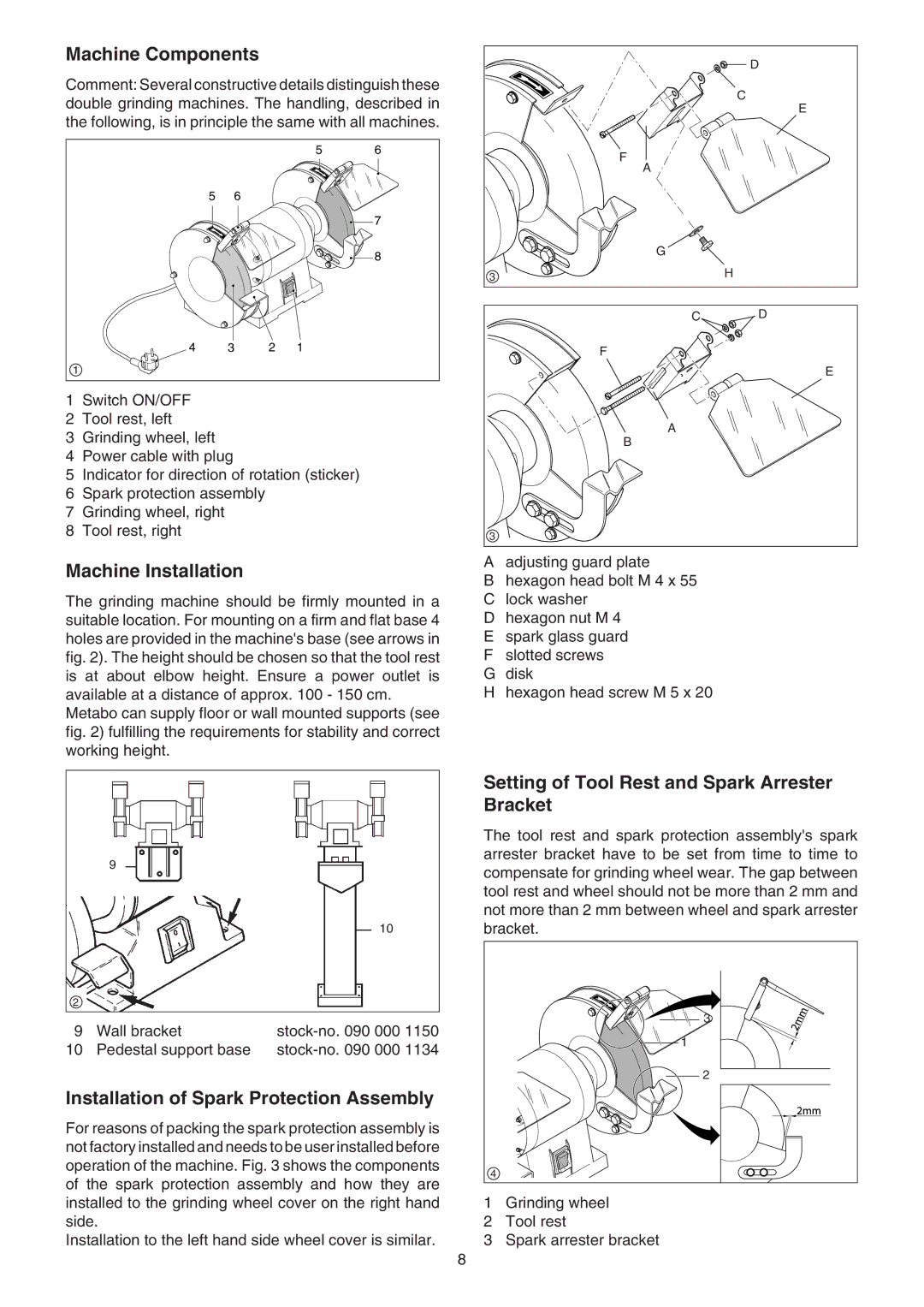

Machine Components

Comment: Several constructive details distinguish these double grinding machines. The handling, described in the following, is in principle the same with all machines.

|

|

| 5 | 6 |

5 | 6 |

|

|

|

|

|

|

| 7 |

|

|

|

| 8 |

4 | 3 | 2 | 1 |

|

1 |

|

|

|

|

1Switch ON/OFF

2 Tool rest, left

3 Grinding wheel, left

4 Power cable with plug

5 Indicator for direction of rotation (sticker)

6 Spark protection assembly

7 Grinding wheel, right

8 Tool rest, right

Machine Installation

The grinding machine should be firmly mounted in a suitable location. For mounting on a firm and flat base 4 holes are provided in the machine's base (see arrows in fig. 2). The height should be chosen so that the tool rest is at about elbow height. Ensure a power outlet is available at a distance of approx. 100 - 150 cm.

Metabo can supply floor or wall mounted supports (see fig. 2) fulfilling the requirements for stability and correct working height.

9

10

2

9 | Wall bracket | |

10 | Pedestal support base |

Installation of Spark Protection Assembly

For reasons of packing the spark protection assembly is not factory installed and needs to be user installed before operation of the machine. Fig. 3 shows the components of the spark protection assembly and how they are installed to the grinding wheel cover on the right hand side.

Installation to the left hand side wheel cover is similar.

| D |

| C |

| E |

F |

|

A |

|

G |

|

3 | H |

| |

C | D |

F |

|

| E |

A |

|

B |

|

3 |

|

A adjusting guard plate

Bhexagon head bolt M 4 x 55 C lock washer

D hexagon nut M 4 E spark glass guard F slotted screws

G disk

H hexagon head screw M 5 x 20

Setting of Tool Rest and Spark Arrester Bracket

The tool rest and spark protection assembly's spark arrester bracket have to be set from time to time to compensate for grinding wheel wear. The gap between tool rest and wheel should not be more than 2 mm and not more than 2 mm between wheel and spark arrester bracket.

3 |

1 |

2 |

4 |

1Grinding wheel

2 Tool rest

3 Spark arrester bracket

8