MODEL 396R pH/ORP | SECTION 5.0 |

| START UP AND CALIBRATION |

5.3396R ORP CALIBRATION. An ORP loop is best calibrated using an ORP standard solution. Most indus- trial applications have a number of ORP reactions occurring in sequence or simultaneously. There can be several components that are oxidized or reduced by the reagents that are used. Theoretically, the ORP potential is absolute because it is the result of the oxi-

5.3.1 ORP Calibration Procedure

1.Make a temporary electrical connection between the sensor and the instrument.

2.Obtain a ORP standard solution (PN

3.Immerse the sensor in the standard solution. Allow

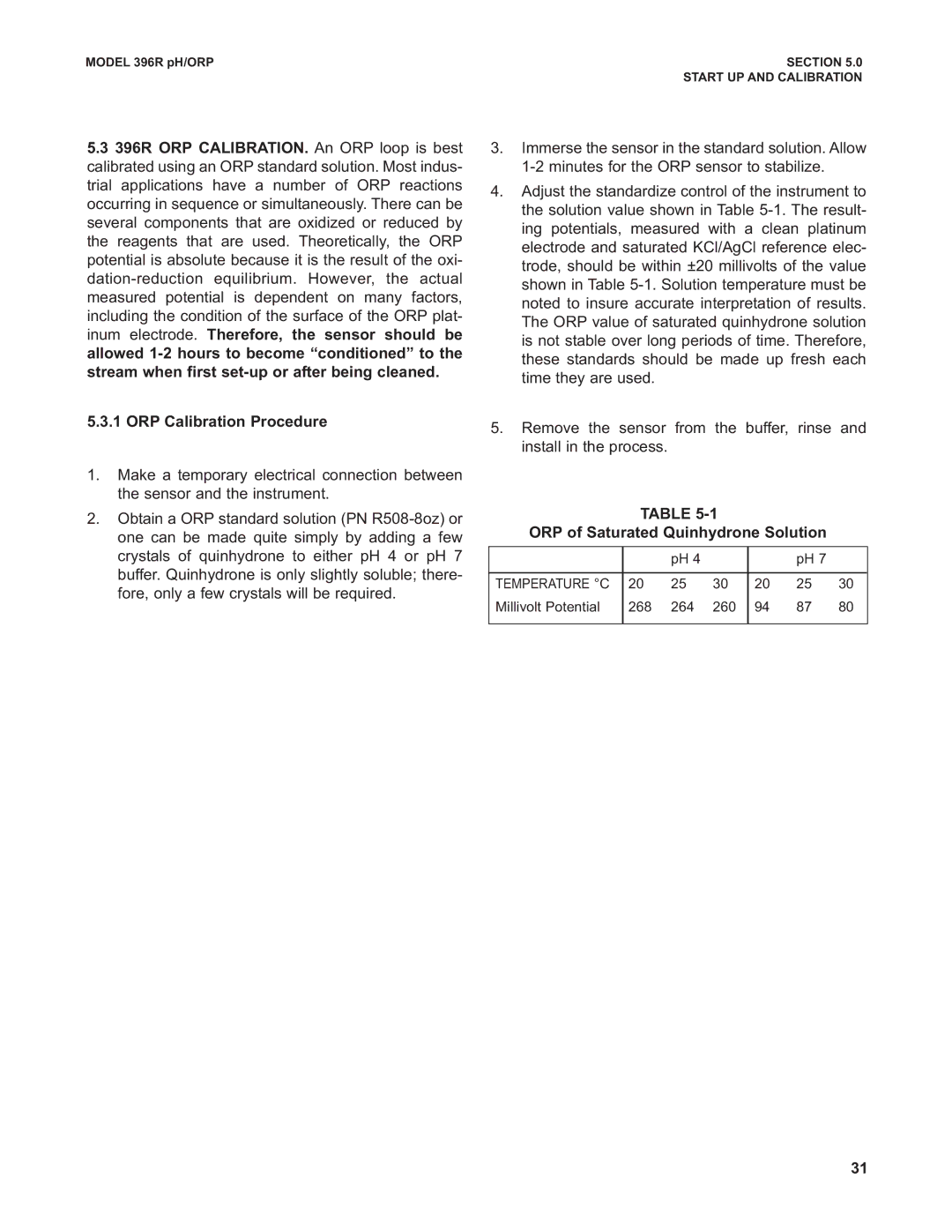

4.Adjust the standardize control of the instrument to the solution value shown in Table

5.Remove the sensor from the buffer, rinse and install in the process.

TABLE

ORP of Saturated Quinhydrone Solution

|

| pH 4 |

|

| pH 7 |

|

|

|

|

|

|

|

|

TEMPERATURE °C | 20 | 25 | 30 | 20 | 25 | 30 |

Millivolt Potential | 268 | 264 | 260 | 94 | 87 | 80 |

|

|

|

|

|

|

|

31