SECTION 4 ADJUSTMENTS

Sensor Adjustments

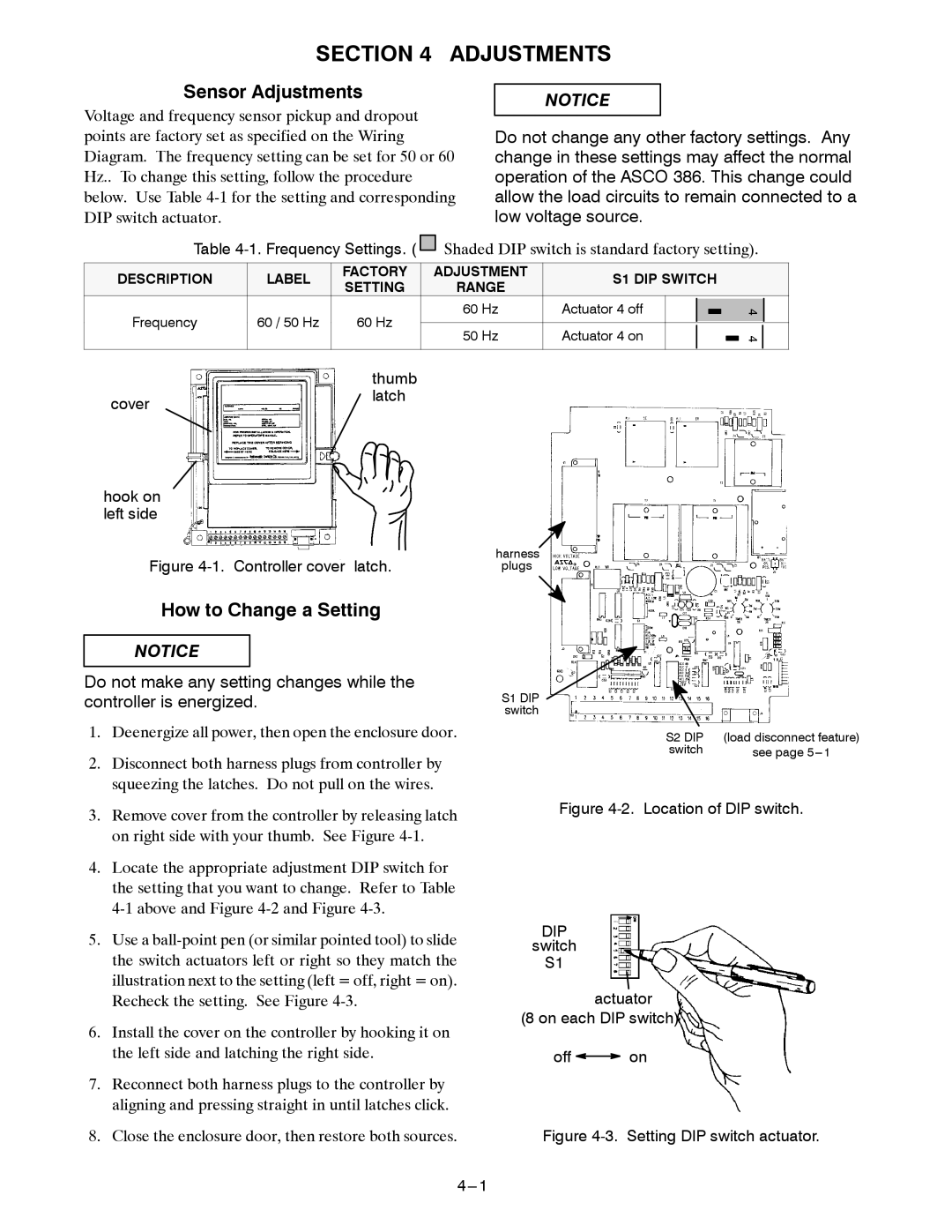

Voltage and frequency sensor pickup and dropout points are factory set as specified on the Wiring Diagram. The frequency setting can be set for 50 or 60 Hz.. To change this setting, follow the procedure below. Use Table

NOTICE

Do not change any other factory settings. Any change in these settings may affect the normal operation of the ASCO 386. This change could allow the load circuits to remain connected to a low voltage source.

Table ![]()

![]() Shaded DIP switch is standard factory setting).

Shaded DIP switch is standard factory setting).

DESCRIPTION | LABEL | FACTORY | ADJUSTMENT | S1 DIP SWITCH | ||||

SETTING | RANGE | |||||||

|

|

|

|

|

| |||

Frequency | 60 / 50 Hz | 60 Hz | 60 Hz | Actuator 4 off |

|

|

| |

|

| |||||||

50 Hz | Actuator 4 on |

|

|

| ||||

|

|

| ||||||

|

|

|

|

| ||||

|

|

|

|

|

|

|

| |

4 4![]()

| thumb |

cover | latch |

|

hook on left side

Figure 4-1. Controller cover latch.

How to Change a Setting

NOTICE

Do not make any setting changes while the controller is energized.

1.Deenergize all power, then open the enclosure door.

2.Disconnect both harness plugs from controller by squeezing the latches. Do not pull on the wires.

3.Remove cover from the controller by releasing latch on right side with your thumb. See Figure

4.Locate the appropriate adjustment DIP switch for the setting that you want to change. Refer to Table

5.Use a

6.Install the cover on the controller by hooking it on the left side and latching the right side.

7.Reconnect both harness plugs to the controller by aligning and pressing straight in until latches click.

8.Close the enclosure door, then restore both sources.

harness plugs

S1 DIP switch

S2 DIP | (load disconnect feature) |

switch | see page |