INSTALLATION (continued)

Functional Test

The Functional Test consists of three checks: manual operation, voltage checks, and electrical operation.

NOTICE

Do these checks in the order presented to avoid damaging the

1 – Manual Operation Test

A detachable maintenance handle is provided on the transfer switch for maintenance purposes only. Manual operation of the switch should be checked before it is energized (operated electrically).

Do not manually operate the transfer switch until both power sources are disconnected: open both circuit breakers.

1.Select the appropriate switch amperage size / design and follow the directions for installing the handle:

260 and 400 amp.

Insert the manual handle into the hole in the shaft, left side of the operator.

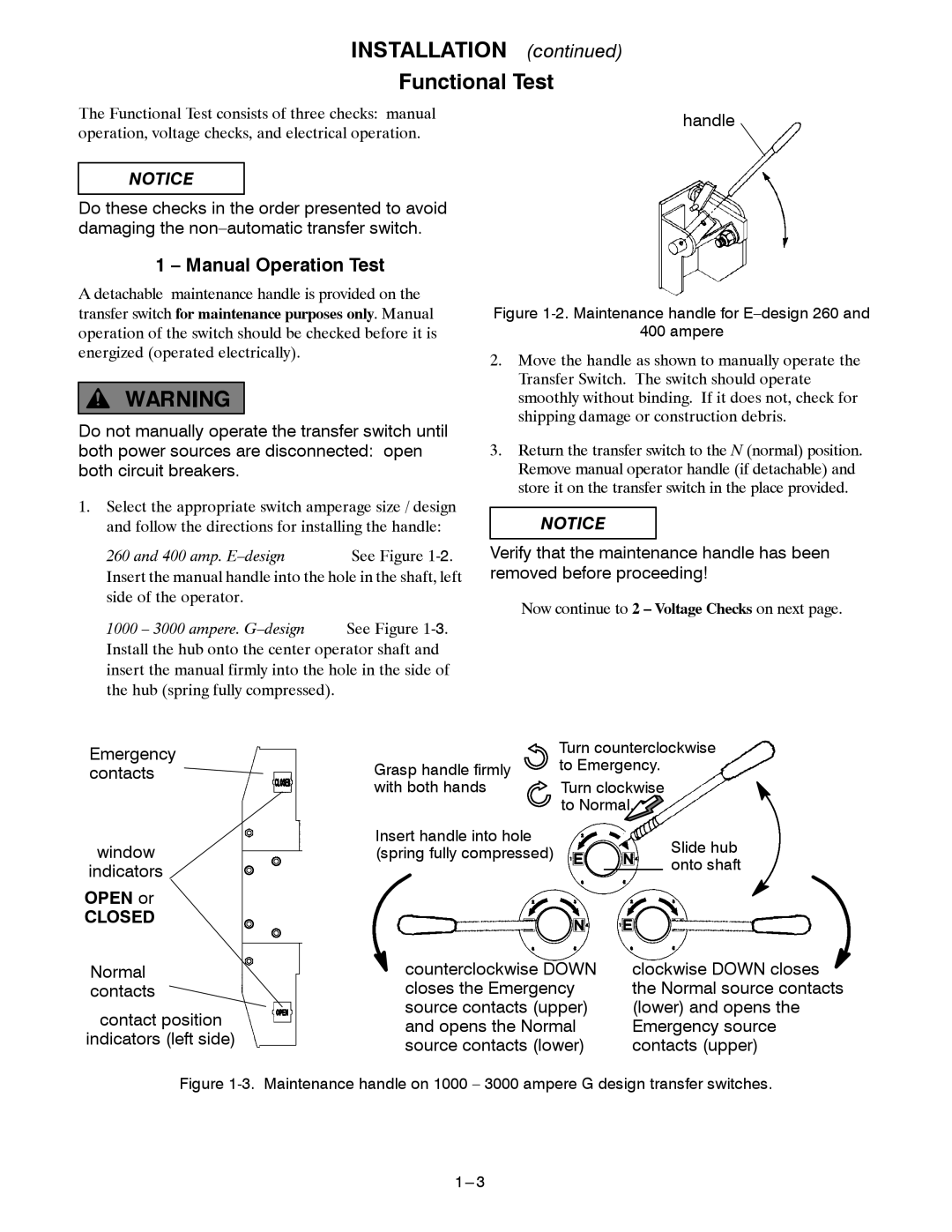

1000 – 3000 ampere. G–design See Figure 1-3.

Install the hub onto the center operator shaft and insert the manual firmly into the hole in the side of the hub (spring fully compressed).

handle

Figure 1-2. Maintenance handle for E–design 260 and

400ampere

2.Move the handle as shown to manually operate the Transfer Switch. The switch should operate smoothly without binding. If it does not, check for shipping damage or construction debris.

3.Return the transfer switch to the N (normal) position. Remove manual operator handle (if detachable) and store it on the transfer switch in the place provided.

NOTICE

Verify that the maintenance handle has been removed before proceeding!

Now continue to 2 – Voltage Checks on next page.

Emergency contacts

window

indicators

OPEN or

CLOSED

Normal

contacts

contact position

indicators (left side)

| Turn counterclockwise | |

Grasp handle firmly | to Emergency. | |

with both hands | Turn clockwise | |

| to Normal. | |

Insert handle into hole | Slide hub | |

(spring fully compressed) | ||

onto shaft | ||

|

counterclockwise DOWN | clockwise DOWN closes |

closes the Emergency | the Normal source contacts |

source contacts (upper) | (lower) and opens the |

and opens the Normal | Emergency source |

source contacts (lower) | contacts (upper) |