INSTALLATION (continued)

Line Connections

A Wiring Diagram is furnished with the ASCO 386 (separate from this manual). Refer to this drawing. All wiring must be made in accordance with the National Electrical Code and local codes.

Bus Connections

If bus connection is used, use SAE grade 5 hardware to connect bus to appropriate terminal plates on the transfer switch. Wipe off bus surfaces before they are joined. If bus is very dirty, gently clean surfaces with a

Testing Power Conductors

Do not connect the power conductors to the transfer switch until they are tested. Installing power cables in conduit, cable troughs and

Connecting Power Conductors

After the power cables have been tested, connect them to the appropriate terminal lugs on the transfer switch as shown on the wiring diagram provided with the switch. Make sure the lugs provided are suitable for use with the cables being installed. Standard terminal lugs are solderless screw type and will accept the wire sizes listed on the drawings provided with the switch. Be careful when stripping insulation from the cables; avoid nicking or ringing the conductor. Remove surface oxides from cables by cleaning with a wire brush. When aluminum cable is used, apply joint compound to conductors. Tighten cable lugs to the torque specified on rating label.

Do not run cables behind the switch. Cables can be bundled on the right side of the switch. Maintain proper electrical clearance between the live metal parts and grounded metal: ½ inch minimum for

Do not breathe cleaning solvent vapors.

Use SAE grade 5 hardware and tighten the bolted joints to the torque specified in Table A.

NOTICE

The reliability of the connection depends on how clean and how tight the joint is.

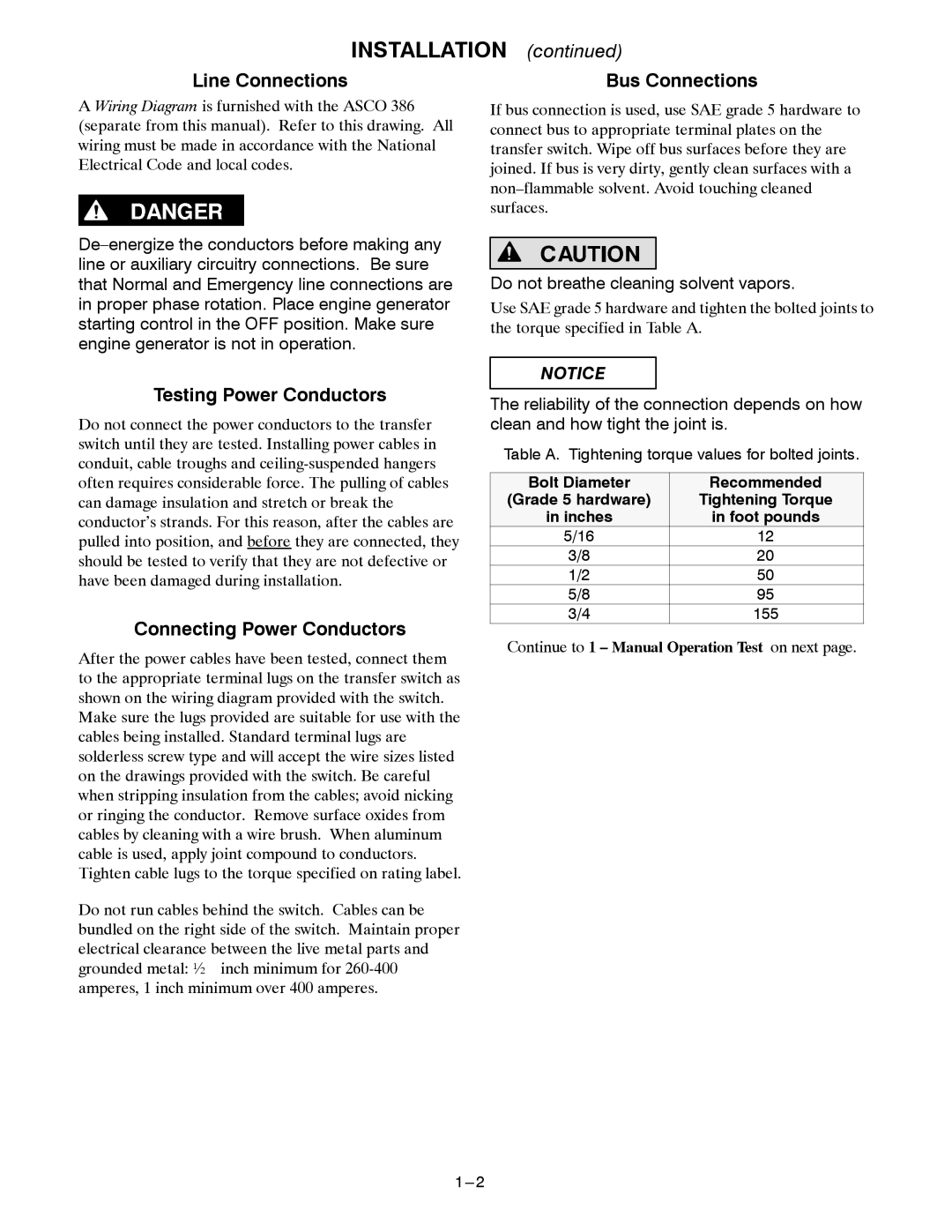

Table A. Tightening torque values for bolted joints.

Bolt Diameter | Recommended |

(Grade 5 hardware) | Tightening Torque |

in inches | in foot pounds |

5/16 | 12 |

3/8 | 20 |

1/2 | 50 |

5/8 | 95 |

3/4 | 155 |

Continue to 1 – Manual Operation Test on next page.