Maintenance and Service Guide

Page

Contents

Removal and Replacement Procedures

Removal and Replacement Preliminaries

Illustrated Parts Catalog

Screw Listing Index

Product Description

Key

Models

Key Description Options

Compaq Evo Notebook N410c Models

Nafta

N410c 120 Asia Pacific 470037-758

N410c 100 Asia Pacific 470040-136

N410c 100 Asia Pacific 470040-177

Compaq Evo Notebook N410c Models

Compaq Evo Notebook N400c Models

470013-752

470013-750

Features

Clearing a Password

Power Management

Front Panel Components

Computer External Components

Component Function

Right Side Components

Right Side Components

Connects the modem cable to an

Left Side Components

Left Side Components

Keyboard Components

Keyboard Components TouchPad Model

Keyboard Components

Keyboard Components

Fn key

Bottom Components

Bottom Components

Rear Panel Components

Rear Panel Components

Design Overview

Computer Setup Diagnostics Utilities

Troubleshooting

Using Computer Setup

Select To Do This

File Menu

Security Menu

Selecting from the Security Menu

Advanced Menu

Selecting from the Advanced Menu

Advanced Menu

Obtaining, Saving, or Printing Configuration Information

Using Compaq Diagnostics

Obtaining, Saving, or Printing Diagnostic Test Information

Maintenance and Service Guide

Troubleshooting Flowcharts Overview

Troubleshooting Flowcharts

Flowchart Description

All drives

Flowchart 2.1 Initial Troubleshooting

Flowchart 2.2 No Power, Part

Flowchart 2.3 No Power, Part

Internal

Flowchart 2.4 No Power, Part

Flowchart 2.5 No Power, Part

Flowchart 2.6 No Video, Part

From Flowchart No Video, Part Remove

Flowchart 2.7 No Video, Part

Backplane board Switch box

Flowchart 2.8 Nonfunctioning Docking Station if applicable

No OS Loading

Flowchart 2.9 No Operating System OS Loading

CD?

Flowchart 2.10 No OS Loading from Hard Drive, Part

Flowchart 2.11 No OS Loading from Hard Drive, Part

Flowchart 2.12 No OS Loading from Hard Drive, Part

Flowchart 2.13 No OS Loading from Diskette Drive

Flowchart 2.14 No OS Loading from CD- or DVD-ROM Drive

Undock

Flowchart 2.15 No Audio, Part

Flowchart 2.16 No Audio, Part

Nonfunctioning Device Reseat

Flowchart 2.17 Nonfunctioning Device

Flowchart 2.18 Nonfunctioning Keyboard

Flowchart 2.19 Nonfunctioning Pointing Device

Flowchart 2.20 No Network or Modem Connection

Serial Number Location

Illustrated Parts Catalog

Computer System Major Components

Computer System Major Components

Palm rests

Computer System Major Components

Description Number Displays

Miscellaneous Plastics Kit

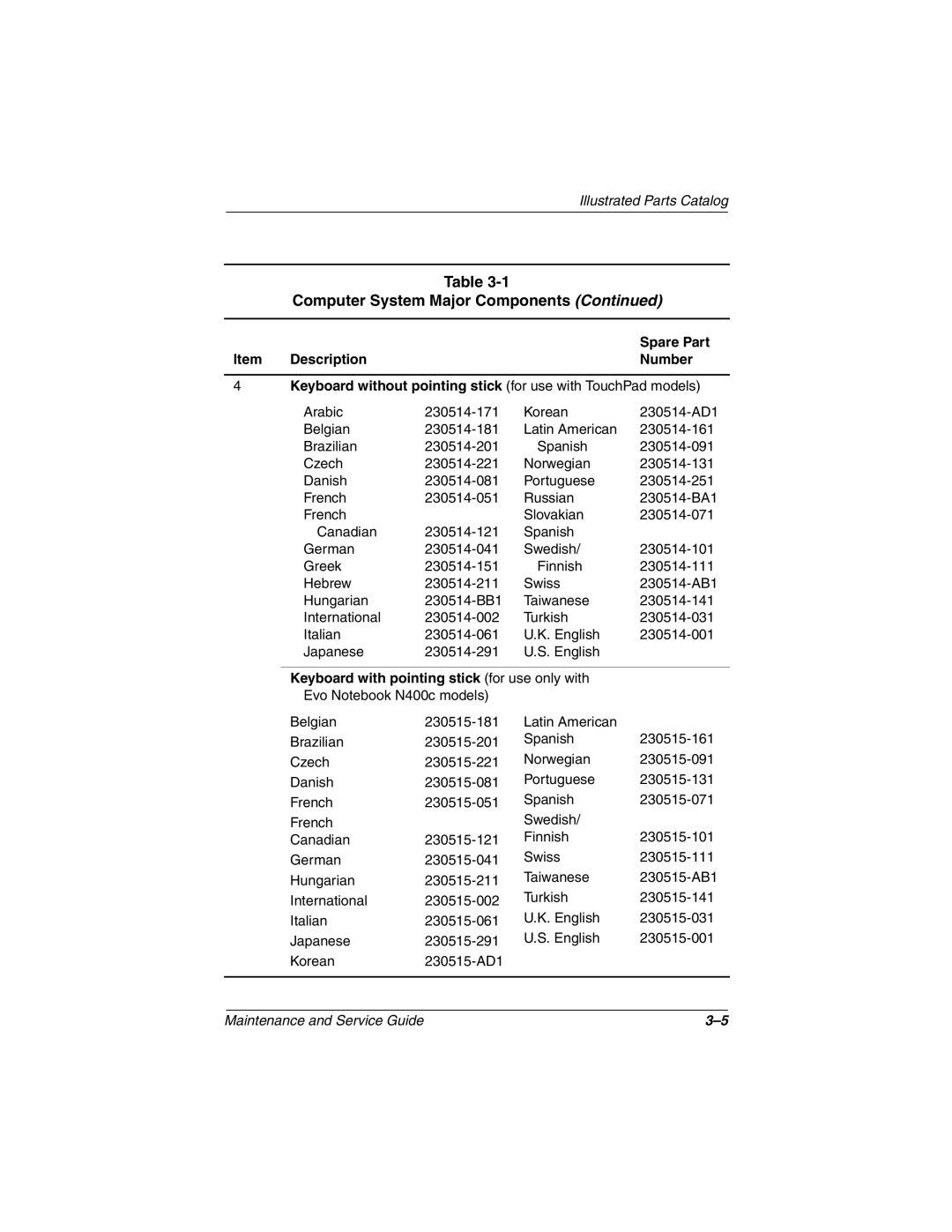

Computer System Major Components

Keyboard with pointing stick for use only with

Computer System Major Components

Spare Part

Description Number Switch cover 231453-001 Hard drives

Base enclosures

Computer System Major Components

Description Number Modem cables

Battery packs

Mini PCI communication boards

Miscellaneous Plastics Kit Components

Miscellaneous Plastics Kit Components

Miscellaneous Plastics Kit Components Spare Part Number

Mass Storage Devices

Mass Storage Devices

Optical drives

Mass Storage Devices

Description Number Hard drives

External diskette drive

Miscellaneous Spare Parts not illustrated

Miscellaneous Spare Parts

Description Number Mobile Expansion Units

RJ-11 P55 adapters

Description Number Modems

Modem adapters

Modem cable

Tools Required

Removal and Replacement Preliminaries

Plastic Parts

Service Considerations

Preventing Damage to Removable Drives

Preventing Electrostatic Damage

Packaging and Transporting Precautions

Workstation Precautions

Grounding Equipment and Methods

Material Use Voltage Protection Level

Typical Electrostatic Voltage Levels

Static-Shielding Materials

Relative Humidity Event 10% 40% 55%

Serial Number

Removal and Replacement Procedures

Section Description Removed

Disassembly Sequence Chart

Disassembly Sequence Chart

# of Screws

Preparing the Notebook for Disassembly

Removing the Primary Battery Pack

Removing the Optional External Battery Pack

Replacing the Computer Feet

Computer Feet

Palm Rest Spare Part Number Information

Palm Rest

Removing the Palm Rest Screws

Releasing the Palm Rest

Releasing the Palm Rest

Releasing the Palm Rest

Removal and Replacement Procedures

10. Disconnecting the Pointing Stick Button Cable

Memory Expansion Board

11. Routing the RTC Battery and TouchPad Cables

12. Removing the Memory Expansion Compartment Cover

13. Removing a Memory Expansion Board

14. Removing a Memory Expansion Board

Hard Drive

Hard Drive

Reverse the above procedure to install the hard drive

Mini PCI Communications Board Spare Part Number Information

Mini PCI Communications Board

Reverse the above procedure to install the modem/NIC board

Keyboard Spare Part Number Information

Keyboard

17. Removing the Keyboard Screws

18. Releasing the Keyboard

Reverse the above procedure to install the keyboard

20. Removing the RTC Battery

Real Time Clock RTC Battery

Switch Cover Spare Part Number Information

Switch Cover

Reverse the above procedure to install the switch cover

Display Spare Part Number Information

Display

23. Removing the Display

Maintenance and Service Guide

Modem Cable Spare Part Number Information

Modem Cable

25. Removing the Right Display Support

26. Removing the Modem Cable on Evo Notebook N410c Models

27. Removing the Modem Cable on Evo Notebook N410c Models

Reverse the above procedure to install the modem cable

System Board Spare Part Number Information

System Board

29. Removing the Center Display Support

30. Removing the System Board Screw

31. Removing the System Board Screws and Screwlocks

Maintenance and Service Guide

Removal and Replacement Procedures

Maintenance and Service Guide

Reverse the above procedure to install the system board

36. Installing the System Board

Removal and Replacement Procedures

Computer

Shock

Relative humidity

Vibration

Inch XGA, TFT Display

Inch SVGA, TFT Display

Hard Drives

Speed Transfer rate

40 GB 30 GB 20 GB Physical configuration

Buffer size3

Disk rotational

Diskette Drive

CD-ROM Drive

Track pitch

DVD-ROM Drive

Audio output level

Energy

Battery Packs

Environmental requirements

Hardware DMA System Function

Power supply input

AC Adapter

System DMA

Hardware IRQ System Function

System Interrupts

System I/O Addresses

16F Unused

VGA

Size Memory Address System Function

System Memory Map

Table A-1 Parallel

Pin Signal

Table A-2 Serial

Pin Signal Audio out

Table A-3 Stereo Speaker/Headphone

Table A-4 Microphone

Pin Signal Audio

Table A-5 Universal Serial Bus

Table A-7 RJ-11 Modem

Table A-6 RJ-45 Network Interface

Table A-8 External Monitor

Conductor Power Cord Set

Power Cord Set Requirements

Country-Specific Requirements

Conductor Power Cord Set Requirements

Country Accredited Agency Applicable Note Number

BSI

Screw Listing

Table C-1 Phillips P0 Metric 2.0 × 3.0 Screw

Color Qty Length Thread Width Silver Where used

Head

Table C-2 Torx T8 Metric 2.0 × 6.0 Screw

Color Qty Length Thread Width Black Where used

Figure C-3. TM2.0 × 6.0 Screw Locations

Figure C-4. TM2.0 × 6.0 Screw Locations

Head Color Qty Length Thread Width

Table C-3 Phillips P0 Metric 2.0 × 5.0 Screw

Figure C-6. TM2.0 × 4.0 Screw Location

Table C-4 Phillips P0 Metric 2.0 × 4.0 Screw

Figure C-7. TM2.0 × 4.0 Screw Location

Figure C-8. PM2.0 × 7.0 Barrel Screw Location

Table C-5 Phillips P0 Metric 2.0 × 7.0 Barrel Screw

Figure C-9. TM2.0 × 4.0 Screw Locations

Table C-5 Torx T8 Metric 2.0 × 4.0 Screw

Figure C-10. HM5.0 × 9.5 Screwlock Locations

Table C-6 Mm × 9.5 Screwlock

Index

Index-2

Index-3

Index-4

Index-5

Index-6