Installation | |

|

|

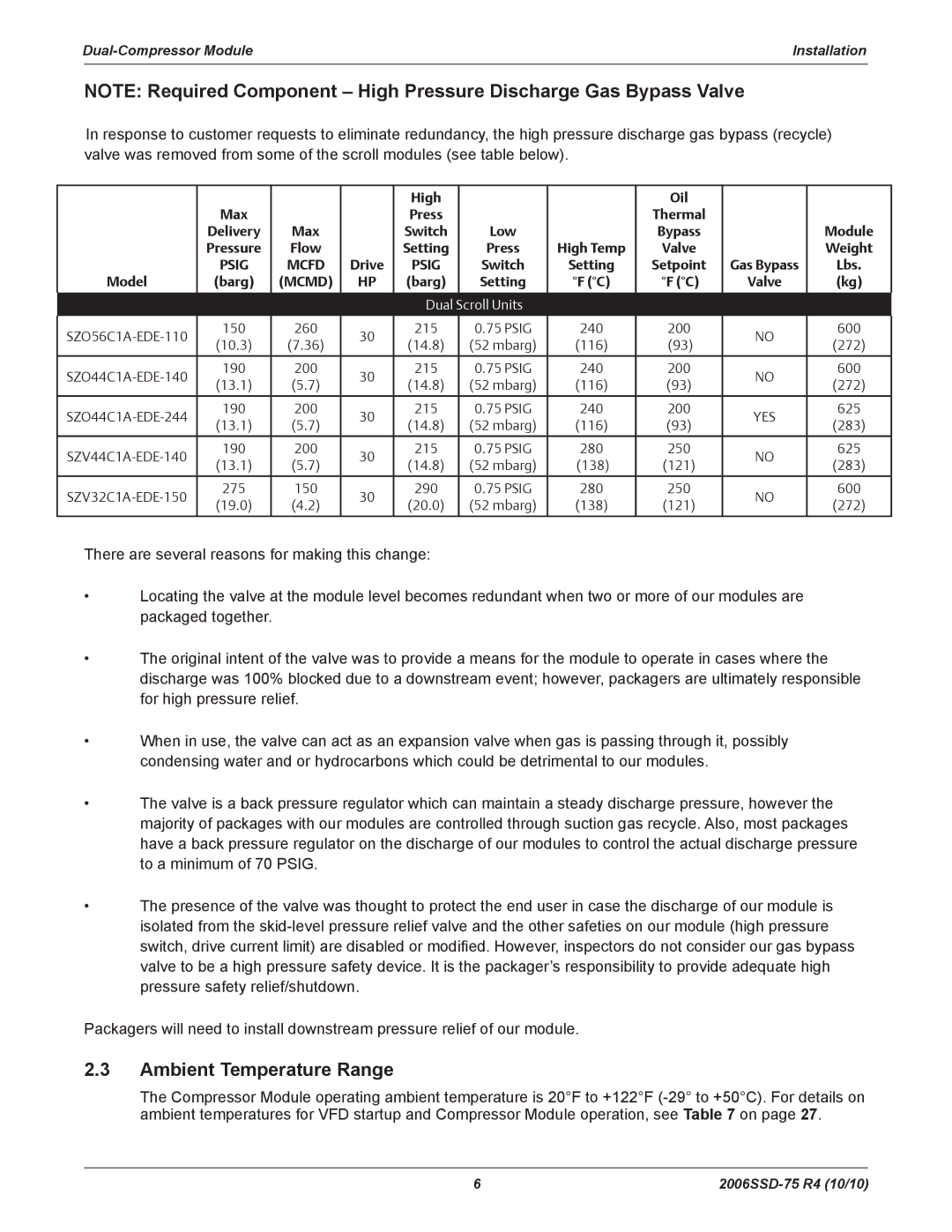

NOTE: Required Component – High Pressure Discharge Gas Bypass Valve

In response to customer requests to eliminate redundancy, the high pressure discharge gas bypass (recycle) valve was removed from some of the scroll modules (see table below).

Model

Max

Delivery Max

Pressure Flow

PSIG MCFD Drive

(barg) (MCMD) HP

High |

|

Press |

|

Switch | Low |

Setting | Press |

PSIG | Switch |

(barg) | Setting |

|

|

Dual Scroll Units

High Temp

Setting

°F (°C)

Oil |

|

Thermal |

|

Bypass |

|

Valve |

|

Setpoint | Gas Bypass |

°F (°C) | Valve |

Module Weight Lbs. (kg)

150 | 260 | 30 | 215 | 0.75 PSIG | 240 | 200 | NO | 600 | ||

(10.3) | (7.36) | (14.8) | (52 mbarg) | (116) | (93) | (272) | ||||

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| |

190 | 200 | 30 | 215 | 0.75 PSIG | 240 | 200 | NO | 600 | ||

(13.1) | (5.7) | (14.8) | (52 mbarg) | (116) | (93) | (272) | ||||

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| |

190 | 200 | 30 | 215 | 0.75 PSIG | 240 | 200 | YES | 625 | ||

(13.1) | (5.7) | (14.8) | (52 mbarg) | (116) | (93) | (283) | ||||

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| |

190 | 200 | 30 | 215 | 0.75 PSIG | 280 | 250 | NO | 625 | ||

(13.1) | (5.7) | (14.8) | (52 mbarg) | (138) | (121) | (283) | ||||

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| |

275 | 150 | 30 | 290 | 0.75 PSIG | 280 | 250 | NO | 600 | ||

(19.0) | (4.2) | (20.0) | (52 mbarg) | (138) | (121) | (272) | ||||

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

There are several reasons for making this change:

•Locating the valve at the module level becomes redundant when two or more of our modules are packaged together.

•The original intent of the valve was to provide a means for the module to operate in cases where the discharge was 100% blocked due to a downstream event; however, packagers are ultimately responsible for high pressure relief.

•When in use, the valve can act as an expansion valve when gas is passing through it, possibly condensing water and or hydrocarbons which could be detrimental to our modules.

•The valve is a back pressure regulator which can maintain a steady discharge pressure, however the majority of packages with our modules are controlled through suction gas recycle. Also, most packages have a back pressure regulator on the discharge of our modules to control the actual discharge pressure to a minimum of 70 PSIG.

•The presence of the valve was thought to protect the end user in case the discharge of our module is isolated from the

Packagers will need to install downstream pressure relief of our module.

2.3Ambient Temperature Range

The Compressor Module operating ambient temperature is 20°F to +122°F

6 |