Maintenance | |

|

|

Replacing Oil

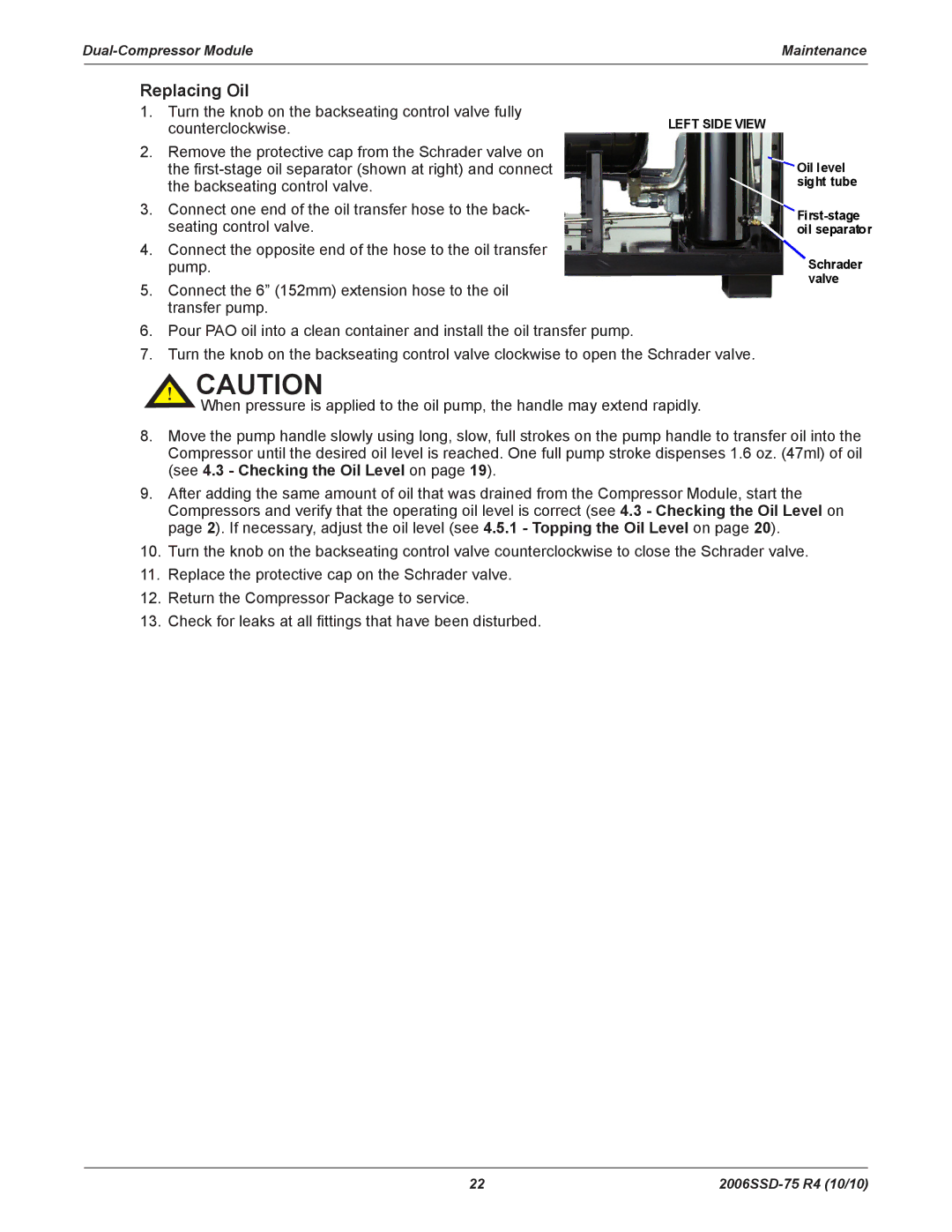

1. Turn the knob on the backseating control valve fully | LEFT SIDE VIEW |

counterclockwise. |

2.Remove the protective cap from the Schrader valve on the

3.Connect one end of the oil transfer hose to the back- seating control valve.

4.Connect the opposite end of the hose to the oil transfer pump.

5.Connect the 6” (152mm) extension hose to the oil transfer pump.

6.Pour PAO oil into a clean container and install the oil transfer pump.

7.Turn the knob on the backseating control valve clockwise to open the Schrader valve.

Caution

When pressure is applied to the oil pump, the handle may extend rapidly.

Oil level sight tube

Schrader valve

8.Move the pump handle slowly using long, slow, full strokes on the pump handle to transfer oil into the Compressor until the desired oil level is reached. One full pump stroke dispenses 1.6 oz. (47ml) of oil (see 4.3 - Checking the Oil Level on page 19).

9.After adding the same amount of oil that was drained from the Compressor Module, start the Compressors and verify that the operating oil level is correct (see 4.3 - Checking the Oil Level on page 2). If necessary, adjust the oil level (see 4.5.1 - Topping the Oil Level on page 20).

10.Turn the knob on the backseating control valve counterclockwise to close the Schrader valve.

11.Replace the protective cap on the Schrader valve.

12.Return the Compressor Package to service.

13.Check for leaks at all fittings that have been disturbed.

22 |