Technical Guide

August 2007

METER PERFORMANCE IN HIGH VISCOSITY LIQUIDS

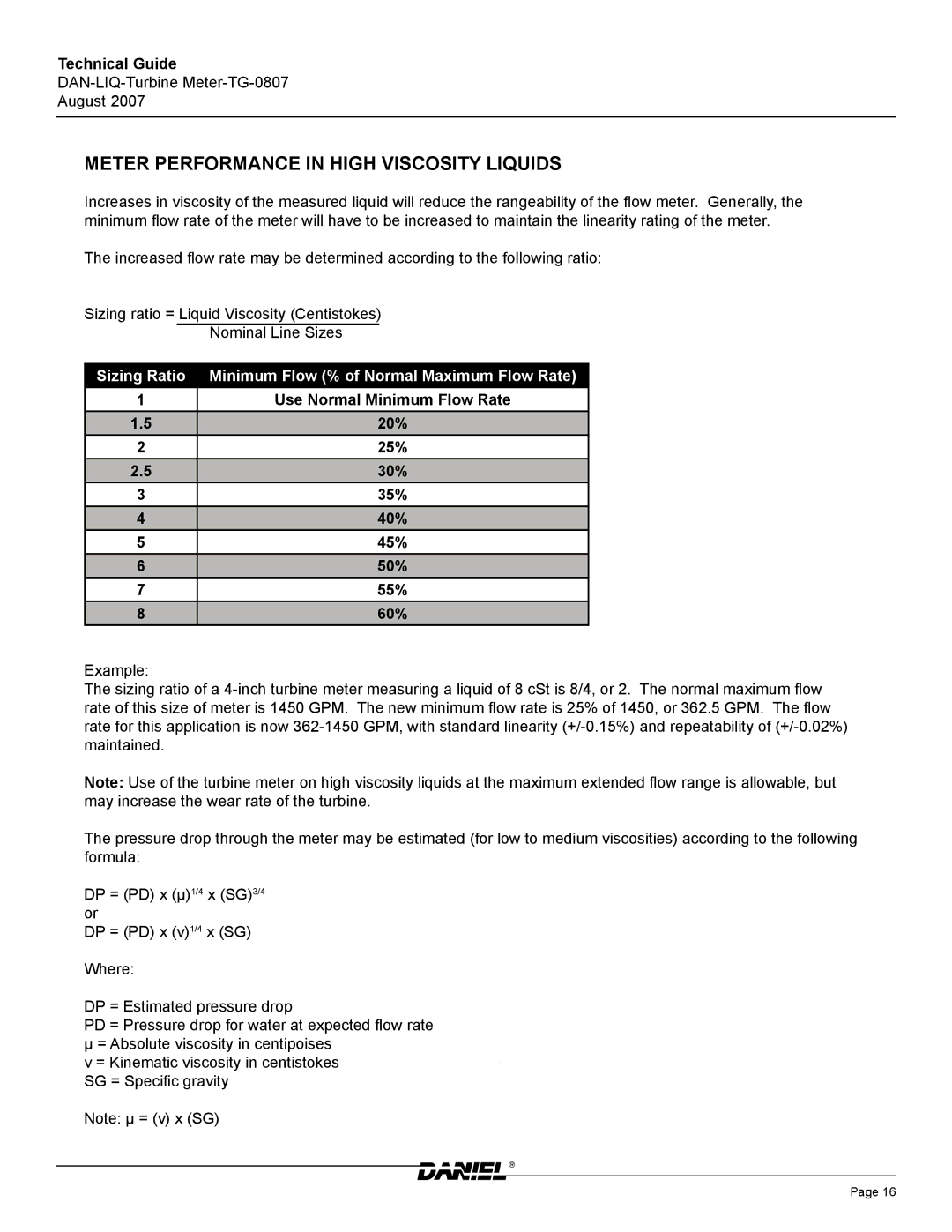

Increases in viscosity of the measured liquid will reduce the rangeability of the flow meter. Generally, the minimum flow rate of the meter will have to be increased to maintain the linearity rating of the meter.

The increased flow rate may be determined according to the following ratio:

Sizing ratio = Liquid Viscosity (Centistokes)

| Nominal Line Sizes |

|

|

Sizing Ratio | Minimum Flow (% of Normal Maximum Flow Rate) |

1 | Use Normal Minimum Flow Rate |

1.5 | 20% |

2 | 25% |

2.5 | 30% |

3 | 35% |

4 | 40% |

5 | 45% |

6 | 50% |

7 | 55% |

8 | 60% |

Example:

The sizing ratio of a

Note: Use of the turbine meter on high viscosity liquids at the maximum extended flow range is allowable, but may increase the wear rate of the turbine.

The pressure drop through the meter may be estimated (for low to medium viscosities) according to the following formula:

DP = (PD) x (μ)1/4 x (SG)3/4 or

DP = (PD) x (v)1/4 x (SG)

Where:

DP = Estimated pressure drop

PD = Pressure drop for water at expected flow rate

μ= Absolute viscosity in centipoises v = Kinematic viscosity in centistokes SG = Specific gravity

Note: μ = (v) x (SG)

Page 16