Technical Guide

August 2007

INSTALLATION AND OPERATING RECOMMENDATIONS

For a turbine meter to perform without increased uncertainty and in a repeatable and accurate manner, the flowing stream must be free of rotational components. The internal assembly supports of a turbine meter offer a slight straightening effect, but additional flow straightening is normally required.

Generally, upstream flow straightening is effected through the use of adequate upstream straightening sections, which often comprise a set of straightening vanes or a tube bundle. Guidance on this subject is offered in the API Manual of Petroleum Measurement Standards, Chapter 5, Section 3.

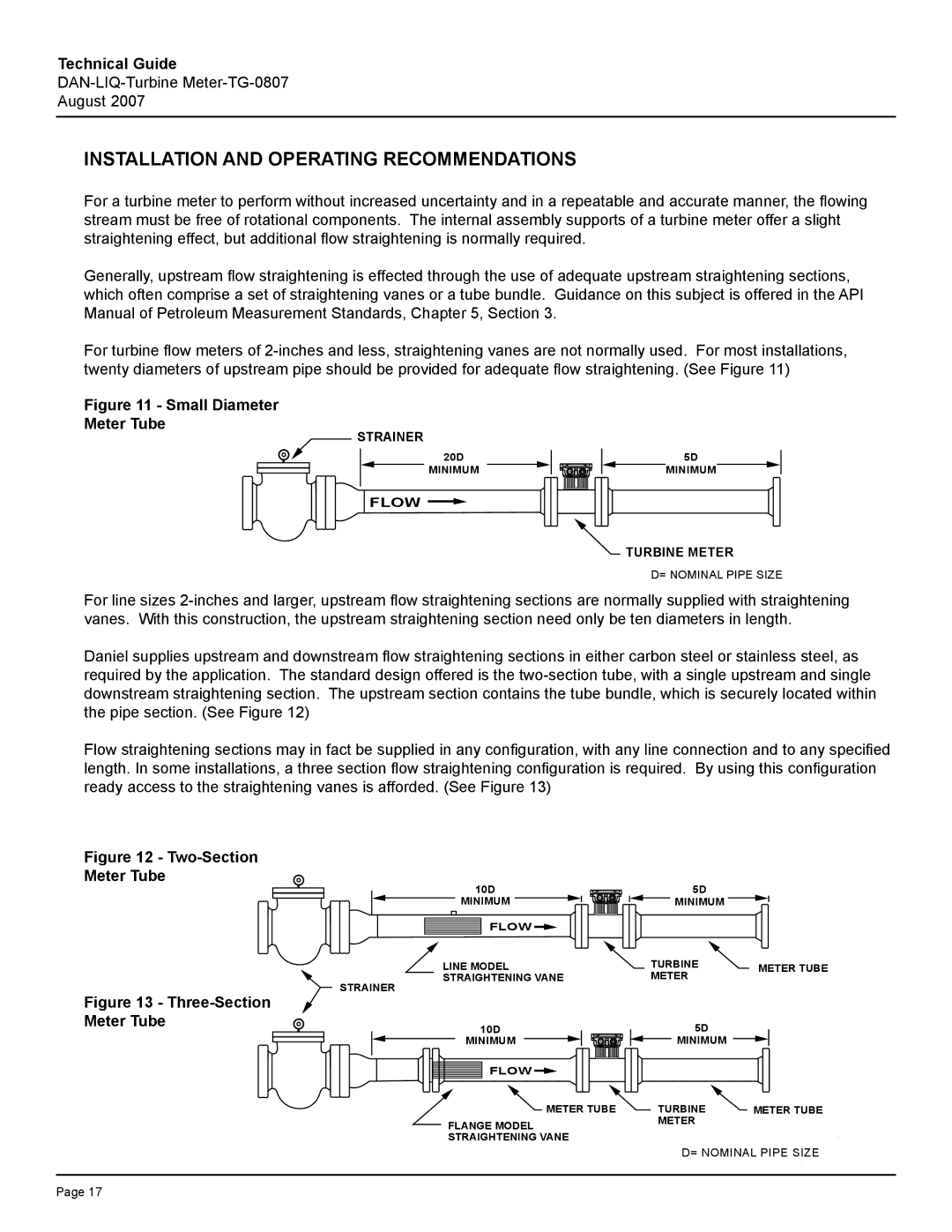

For turbine flow meters of

Figure 11 - Small Diameter

Meter Tube

STRAINER

20D

MINIMUM

FLOW ![]()

5D

MINIMUM

![]() TURBINE METER

TURBINE METER

D= NOMINAL PIPE SIZE

For line sizes

Daniel supplies upstream and downstream flow straightening sections in either carbon steel or stainless steel, as required by the application. The standard design offered is the

Flow straightening sections may in fact be supplied in any configuration, with any line connection and to any specified length. In some installations, a three section flow straightening configuration is required. By using this configuration ready access to the straightening vanes is afforded. (See Figure 13)

Figure 12 - Two-Section

Meter Tube

10D |

MINIMUM |

FLOW ![]()

5D

MINIMUM ![]()

![]()

Figure 13 - Three-Section Meter Tube

LINE MODEL | TURBINE | METER TUBE |

STRAIGHTENING VANE | METER |

|

STRAINER |

|

|

10D | 5D |

MINIMUM | MINIMUM |

FLOW |

|

METER TUBE | TURBINE | METER TUBE |

FLANGE MODEL | METER |

|

STRAIGHTENING VANE |

|

|

D= NOMINAL PIPE SIZE

Page 17