Technical Guide

August 2007

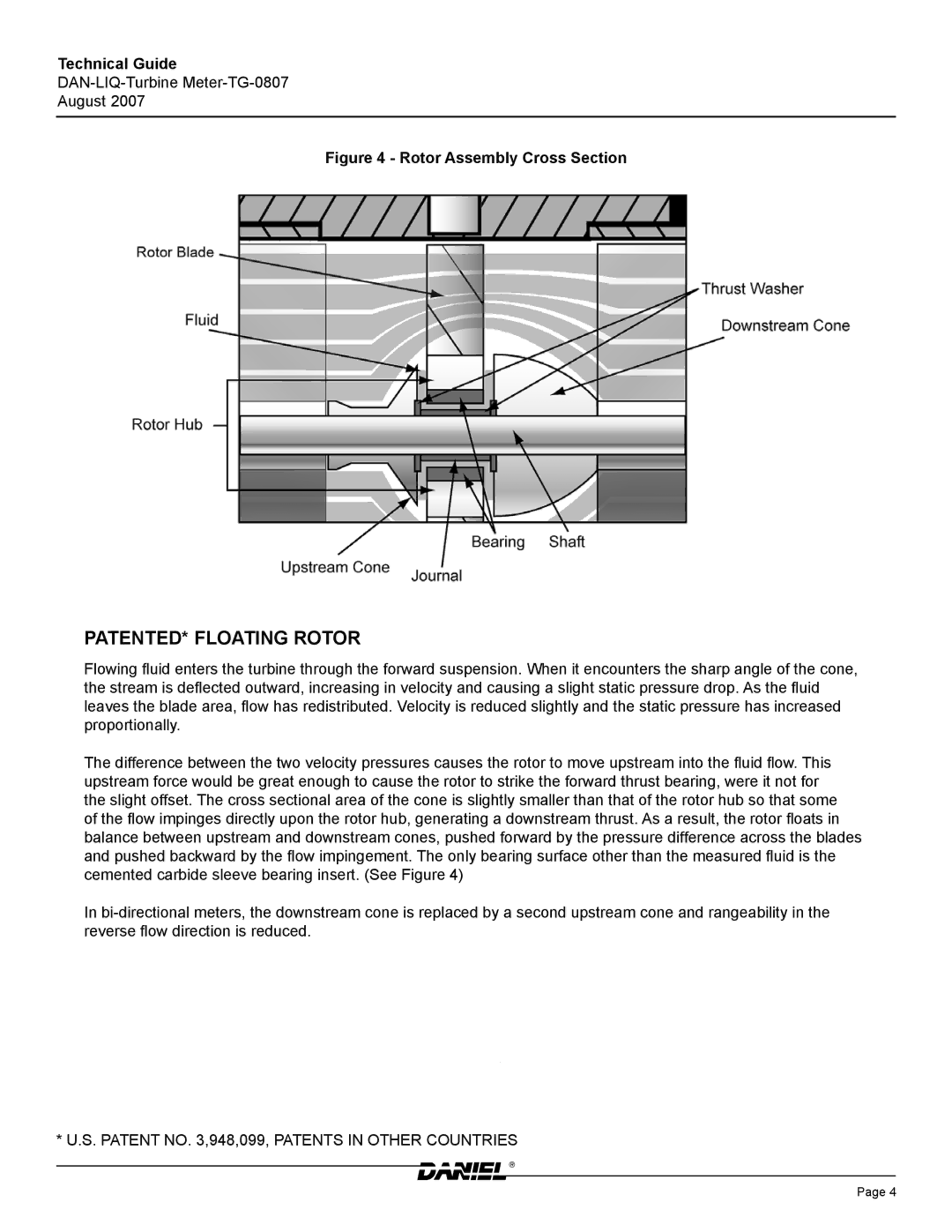

Figure 4 - Rotor Assembly Cross Section

Patented* Floating Rotor

Flowing fluid enters the turbine through the forward suspension. When it encounters the sharp angle of the cone, the stream is deflected outward, increasing in velocity and causing a slight static pressure drop. As the fluid leaves the blade area, flow has redistributed. Velocity is reduced slightly and the static pressure has increased proportionally.

The difference between the two velocity pressures causes the rotor to move upstream into the fluid flow. This upstream force would be great enough to cause the rotor to strike the forward thrust bearing, were it not for the slight offset. The cross sectional area of the cone is slightly smaller than that of the rotor hub so that some of the flow impinges directly upon the rotor hub, generating a downstream thrust. As a result, the rotor floats in balance between upstream and downstream cones, pushed forward by the pressure difference across the blades and pushed backward by the flow impingement. The only bearing surface other than the measured fluid is the cemented carbide sleeve bearing insert. (See Figure 4)

In

* U.S. PATENT NO. 3,948,099, PATENTS IN OTHER COUNTRIES

Page