#8 x 3/8" (9mm) screws provided.

8.Align clearance holes on 6" x 10" (152mm x 254mm) duct with screw holes on inner casing back and mark duct to be 2 1/4" (57mm) shorter than 8" x 12" (203mm x 305mm) boot. Remove duct and cut to proper length.

9.Attach 6" x 10" (152mm x 254mm) duct to inner casing back with

(4) #8 x 3/8" (9mm)screws removed in Step 3, 2 on top and 2 on bottom.

10.Insert rear register into 8" x 12" (203mm x 305mm) boot. Attach rear register to wall with (2) #10 x 1"(25mm) screws provided.

11.Installation of

Locating Furnace On Wall

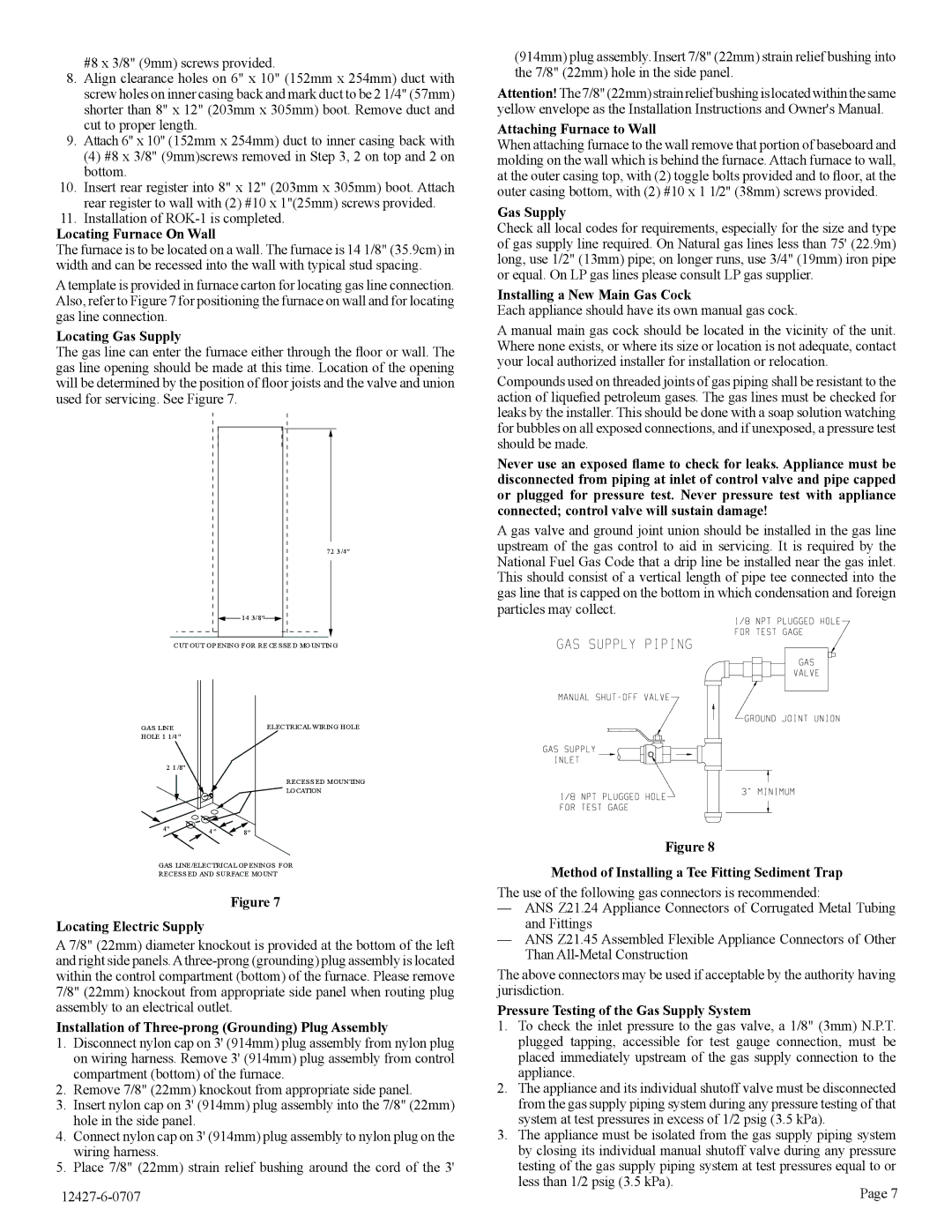

The furnace is to be located on a wall. The furnace is 14 1/8" (35.9cm) in width and can be recessed into the wall with typical stud spacing.

A template is provided in furnace carton for locating gas line connection. Also, refer to Figure 7 for positioning the furnace on wall and for locating gas line connection.

Locating Gas Supply

The gas line can enter the furnace either through the floor or wall. The gas line opening should be made at this time. Location of the opening will be determined by the position of floor joists and the valve and union used for servicing. See Figure 7.

72 3/4"

![]() 14 3/8"

14 3/8"![]()

CUT OUT OP ENING FOR RE CE SSE D MO UNTING

GAS LINE |

| ELECTRICAL WIRING HOLE |

HOLE 1 1/4" |

|

|

2 1/8" |

|

|

|

| RECESS ED MOUNTING |

|

| LO CATION |

4" | 4" | 8" |

|

GAS LINE /ELECTRICAL OP ENINGS FOR�

RECESS ED AND SURFACE MO UNT

Figure 7

Locating Electric Supply

A 7/8" (22mm) diameter knockout is provided at the bottom of the left and right side panels. A

Installation of Three-prong (Grounding) Plug Assembly

1.Disconnect nylon cap on 3' (914mm) plug assembly from nylon plug on wiring harness. Remove 3' (914mm) plug assembly from control compartment (bottom) of the furnace.

2.Remove 7/8" (22mm) knockout from appropriate side panel.

3.Insert nylon cap on 3' (914mm) plug assembly into the 7/8" (22mm) hole in the side panel.

4.Connect nylon cap on 3' (914mm) plug assembly to nylon plug on the wiring harness.

5.Place 7/8" (22mm) strain relief bushing around the cord of the 3'

(914mm) plug assembly. Insert 7/8" (22mm) strain relief bushing into the 7/8" (22mm) hole in the side panel.

Attention! The 7/8" (22mm) strain relief bushing is located within the same yellow envelope as the Installation Instructions and Owner's Manual.

Attaching Furnace to Wall

When attaching furnace to the wall remove that portion of baseboard and molding on the wall which is behind the furnace. Attach furnace to wall, at the outer casing top, with (2) toggle bolts provided and to floor, at the outer casing bottom, with (2) #10 x 1 1/2" (38mm) screws provided.

Gas Supply

Check all local codes for requirements, especially for the size and type of gas supply line required. On Natural gas lines less than 75' (22.9m) long, use 1/2" (13mm) pipe; on longer runs, use 3/4" (19mm) iron pipe or equal. On LP gas lines please consult LP gas supplier.

Installing a New Main Gas Cock

Each appliance should have its own manual gas cock.

A manual main gas cock should be located in the vicinity of the unit. Where none exists, or where its size or location is not adequate, contact your local authorized installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant to the action of liquefied petroleum gases. The gas lines must be checked for leaks by the installer. This should be done with a soap solution watching for bubbles on all exposed connections, and if unexposed, a pressure test should be made.

Never use an exposed flame to check for leaks. Appliance must be disconnected from piping at inlet of control valve and pipe capped or plugged for pressure test. Never pressure test with appliance connected; control valve will sustain damage!

A gas valve and ground joint union should be installed in the gas line upstream of the gas control to aid in servicing. It is required by the National Fuel Gas Code that a drip line be installed near the gas inlet. This should consist of a vertical length of pipe tee connected into the gas line that is capped on the bottom in which condensation and foreign particles may collect.

Figure 8

Method of Installing a Tee Fitting Sediment Trap

The use of the following gas connectors is recommended:

—ANS Z21.24 Appliance Connectors of Corrugated Metal Tubing and Fittings

—ANS Z21.45 Assembled Flexible Appliance Connectors of Other Than

The above connectors may be used if acceptable by the authority having jurisdiction.

Pressure Testing of the Gas Supply System

1.To check the inlet pressure to the gas valve, a 1/8" (3mm) N.P.T. plugged tapping, accessible for test gauge connection, must be placed immediately upstream of the gas supply connection to the appliance.

2.The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

3.The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).