Maintenance

Clutch Shim

Some later model year units have been built with clutches that contain a brake shim. When the clutch brake has worn to the point where the clutch no longer engages consistently, the shim can be removed to extend the clutch life.

Figure 16

Right-Hand Side of Unit Shown

1. | 3. Remove | |

| holes to reduce spring | washer. |

| tension. |

|

2. | Weight transfer spring. |

|

7.Re-install the left fender.

8.For additional weight transfer adjustment, repeat steps 4 through 7 on the right side of the unit.

Caster Pivot Bearings Pre-Load Adjustment

Remove dust cap from caster and tighten nyloc nut until washers are flat and back off 1/4 of a turn to properly set the

Figure 17

1.Spring disc washers

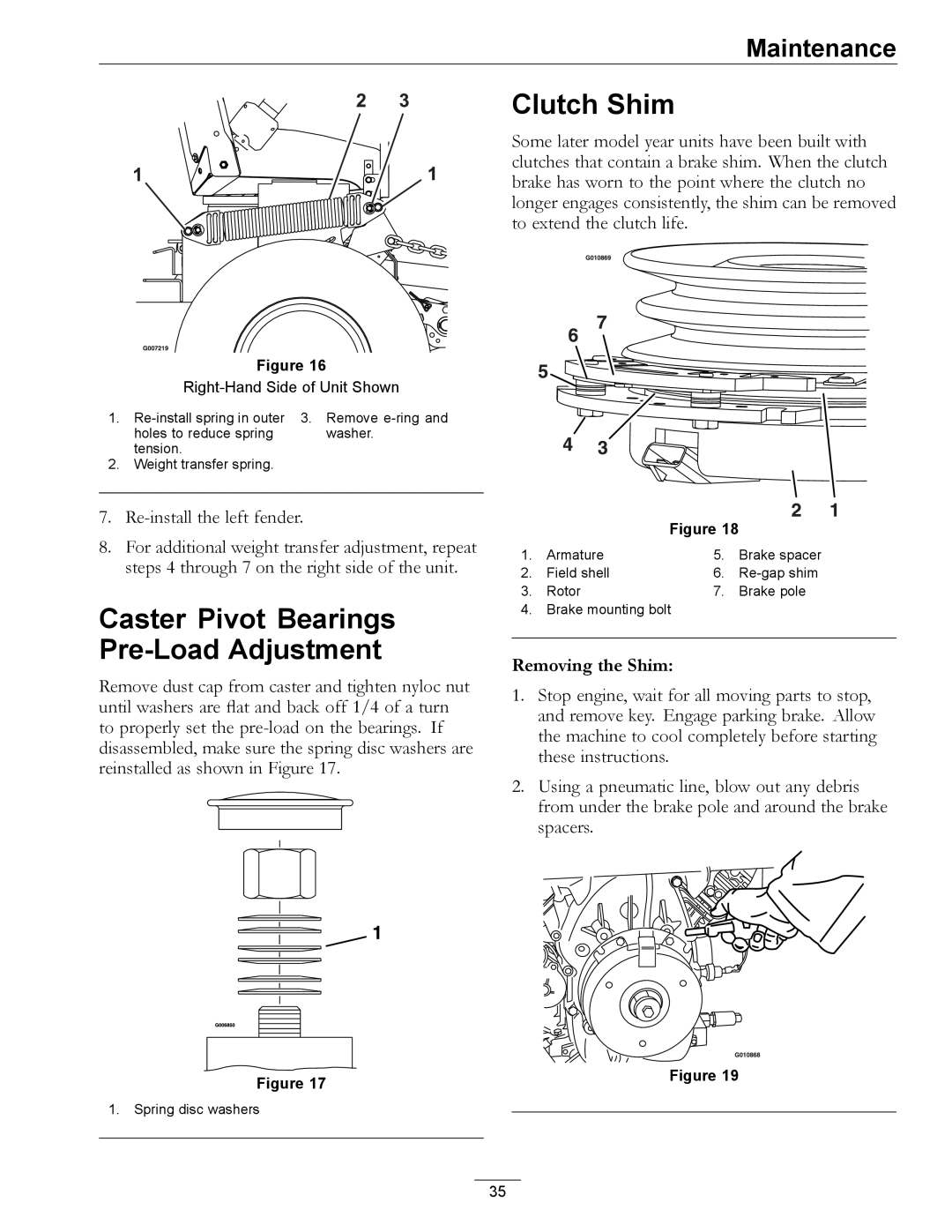

Figure 18

1. | Armature | 5. | Brake spacer |

2. | Field shell | 6. | |

3. | Rotor | 7. | Brake pole |

4. | Brake mounting bolt |

|

|

Removing the Shim:

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Allow the machine to cool completely before starting these instructions.

2.Using a pneumatic line, blow out any debris from under the brake pole and around the brake spacers.

Figure 19

35