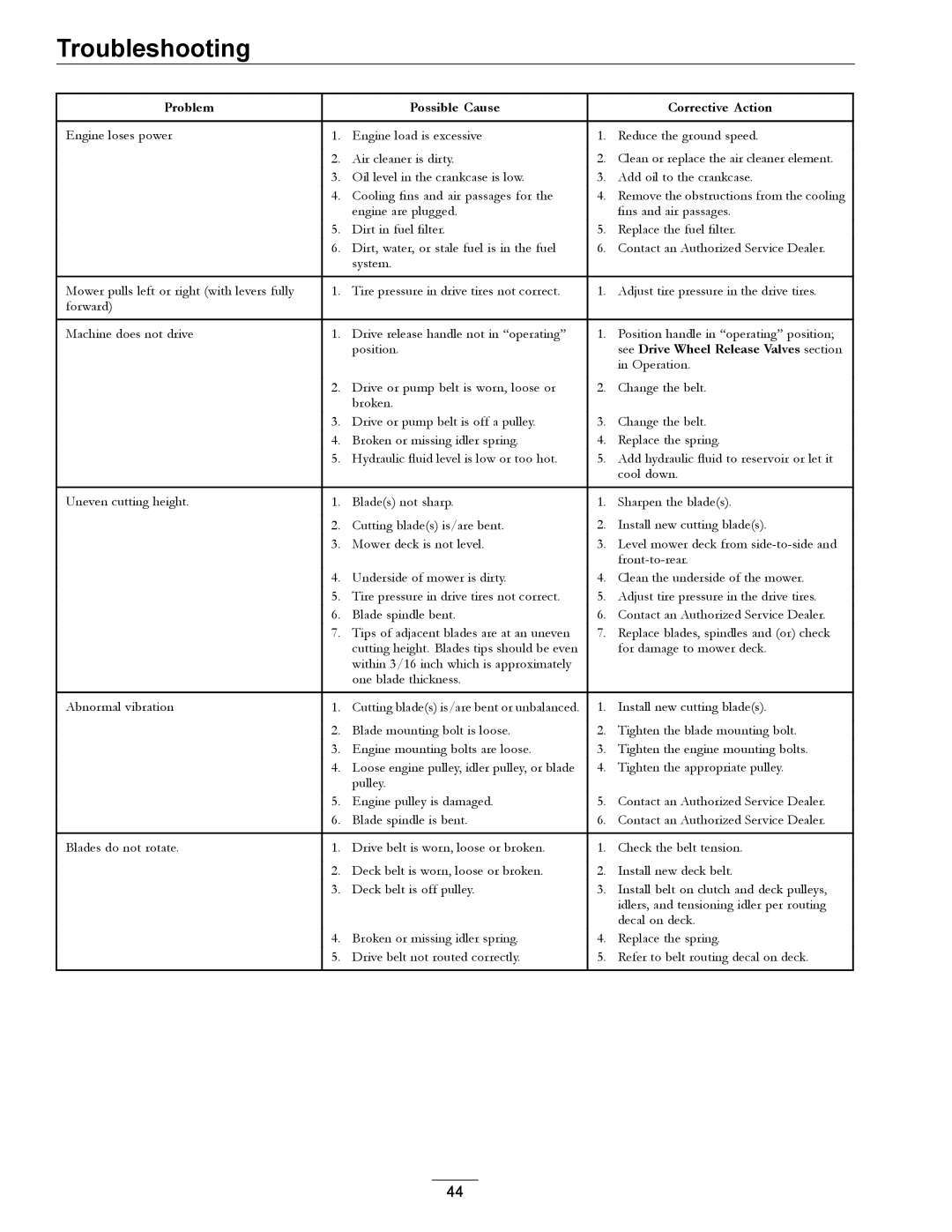

Troubleshooting

Problem |

| Possible Cause |

| Corrective Action |

|

|

|

|

|

Engine loses power | 1. | Engine load is excessive | 1. | Reduce the ground speed. |

| 2. | Air cleaner is dirty. | 2. | Clean or replace the air cleaner element. |

| 3. | Oil level in the crankcase is low. | 3. | Add oil to the crankcase. |

| 4. | Cooling fins and air passages for the | 4. | Remove the obstructions from the cooling |

|

| engine are plugged. |

| fins and air passages. |

| 5. | Dirt in fuel filter. | 5. | Replace the fuel filter. |

| 6. | Dirt, water, or stale fuel is in the fuel | 6. | Contact an Authorized Service Dealer. |

|

| system. |

|

|

|

|

|

|

|

Mower pulls left or right (with levers fully | 1. | Tire pressure in drive tires not correct. | 1. | Adjust tire pressure in the drive tires. |

forward) |

|

|

|

|

|

|

|

|

|

Machine does not drive | 1. | Drive release handle not in “operating” | 1. | Position handle in “operating” position; |

|

| position. |

| see Drive Wheel Release Valves section |

|

|

|

| in Operation. |

| 2. | Drive or pump belt is worn, loose or | 2. | Change the belt. |

|

| broken. |

|

|

| 3. | Drive or pump belt is off a pulley. | 3. | Change the belt. |

| 4. | Broken or missing idler spring. | 4. | Replace the spring. |

| 5. | Hydraulic fluid level is low or too hot. | 5. | Add hydraulic fluid to reservoir or let it |

|

|

|

| cool down. |

|

|

|

|

|

Uneven cutting height. | 1. | Blade(s) not sharp. | 1. | Sharpen the blade(s). |

| 2. | Cutting blade(s) is/are bent. | 2. | Install new cutting blade(s). |

| 3. | Mower deck is not level. | 3. | Level mower deck from |

|

|

|

| |

| 4. | Underside of mower is dirty. | 4. | Clean the underside of the mower. |

| 5. | Tire pressure in drive tires not correct. | 5. | Adjust tire pressure in the drive tires. |

| 6. | Blade spindle bent. | 6. | Contact an Authorized Service Dealer. |

| 7. | Tips of adjacent blades are at an uneven | 7. | Replace blades, spindles and (or) check |

|

| cutting height. Blades tips should be even |

| for damage to mower deck. |

|

| within 3/16 inch which is approximately |

|

|

|

| one blade thickness. |

|

|

|

|

|

|

|

Abnormal vibration | 1. | Cutting blade(s) is/are bent or unbalanced. | 1. | Install new cutting blade(s). |

| 2. | Blade mounting bolt is loose. | 2. | Tighten the blade mounting bolt. |

| 3. | Engine mounting bolts are loose. | 3. | Tighten the engine mounting bolts. |

| 4. | Loose engine pulley, idler pulley, or blade | 4. | Tighten the appropriate pulley. |

|

| pulley. |

|

|

| 5. | Engine pulley is damaged. | 5. | Contact an Authorized Service Dealer. |

| 6. | Blade spindle is bent. | 6. | Contact an Authorized Service Dealer. |

|

|

|

|

|

Blades do not rotate. | 1. | Drive belt is worn, loose or broken. | 1. | Check the belt tension. |

| 2. | Deck belt is worn, loose or broken. | 2. | Install new deck belt. |

| 3. | Deck belt is off pulley. | 3. | Install belt on clutch and deck pulleys, |

|

|

|

| idlers, and tensioning idler per routing |

|

|

|

| decal on deck. |

| 4. | Broken or missing idler spring. | 4. | Replace the spring. |

| 5. | Drive belt not routed correctly. | 5. | Refer to belt routing decal on deck. |

|

|

|

|

|

44