3.12Connect the lower end of the speed control linkage to the speed control crank located at the top rear of the fuel tank support. Secure with clevis pin and hairpin from the bolt bag.

3.13Install drive lever linkages.

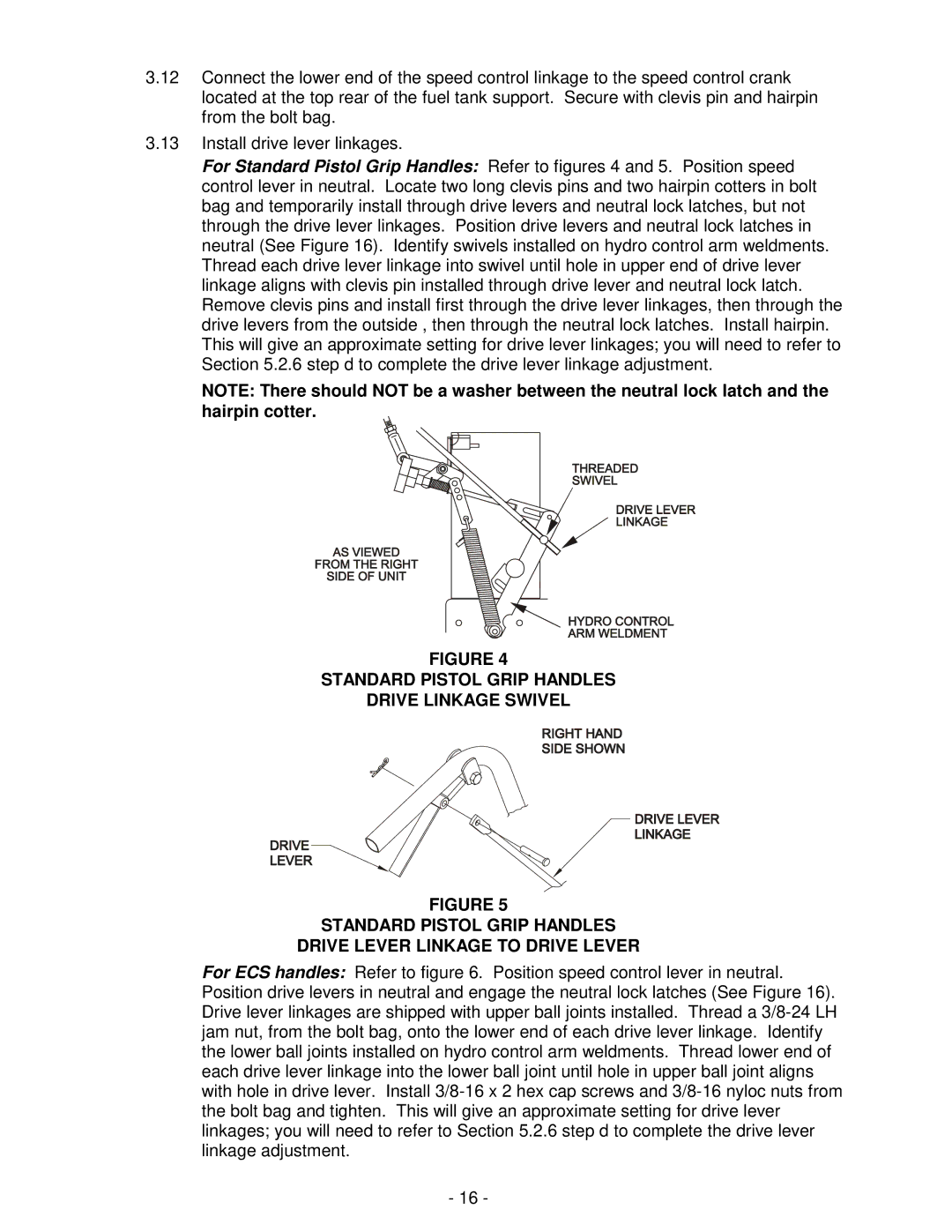

For Standard Pistol Grip Handles: Refer to figures 4 and 5. Position speed control lever in neutral. Locate two long clevis pins and two hairpin cotters in bolt bag and temporarily install through drive levers and neutral lock latches, but not through the drive lever linkages. Position drive levers and neutral lock latches in neutral (See Figure 16). Identify swivels installed on hydro control arm weldments. Thread each drive lever linkage into swivel until hole in upper end of drive lever linkage aligns with clevis pin installed through drive lever and neutral lock latch. Remove clevis pins and install first through the drive lever linkages, then through the drive levers from the outside , then through the neutral lock latches. Install hairpin. This will give an approximate setting for drive lever linkages; you will need to refer to Section 5.2.6 step d to complete the drive lever linkage adjustment.

NOTE: There should NOT be a washer between the neutral lock latch and the hairpin cotter.

FIGURE 4

STANDARD PISTOL GRIP HANDLES

DRIVE LINKAGE SWIVEL

FIGURE 5

STANDARD PISTOL GRIP HANDLES

DRIVE LEVER LINKAGE TO DRIVE LEVER

For ECS handles: Refer to figure 6. Position speed control lever in neutral. Position drive levers in neutral and engage the neutral lock latches (See Figure 16). Drive lever linkages are shipped with upper ball joints installed. Thread a

- 16 -