b)Engage PTO lever.

c)Look through the round hole in the left rear corner of the engine deck to inspect blade clutching belt tension. Bolt on blade engagement linkage bellcrank and indicator arm should align within 1/16” (See Figure 12). Refer to section 5.2.2 for adjustment.

5.1.14Lubrication

Service Interval: Refer to Chart.

a)Stop engine and wait for all moving parts to stop. Remove ignition key or spark plug wire(s).

b)Lubricate fittings with one to two pumps of NGLI grade #2

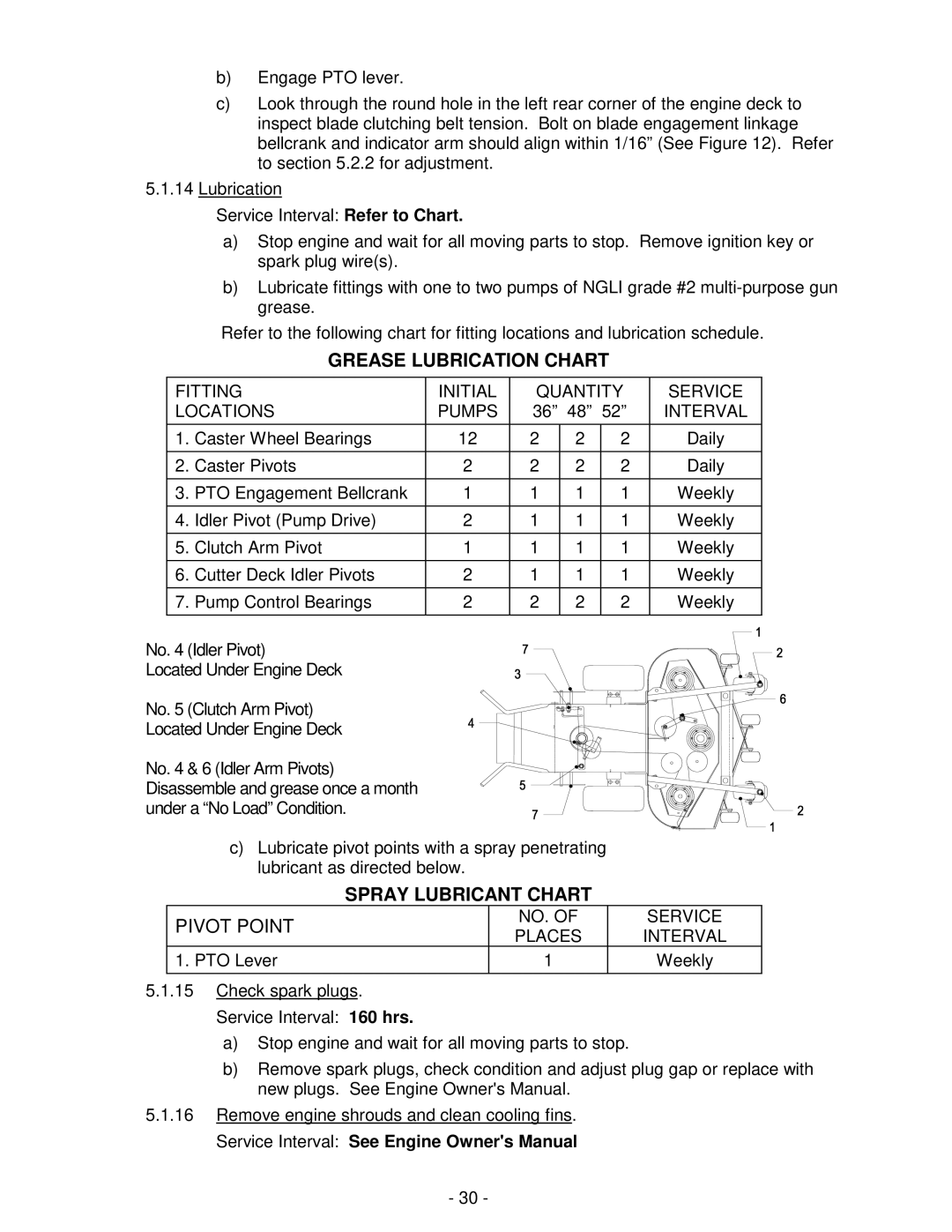

Refer to the following chart for fitting locations and lubrication schedule.

GREASE LUBRICATION CHART

FITTING | INITIAL | QUANTITY | SERVICE | |||

LOCATIONS | PUMPS | 36” 48” 52” | INTERVAL | |||

1. | Caster Wheel Bearings | 12 | 2 | 2 | 2 | Daily |

2. | Caster Pivots | 2 | 2 | 2 | 2 | Daily |

3. | PTO Engagement Bellcrank | 1 | 1 | 1 | 1 | Weekly |

4. | Idler Pivot (Pump Drive) | 2 | 1 | 1 | 1 | Weekly |

5. | Clutch Arm Pivot | 1 | 1 | 1 | 1 | Weekly |

6. | Cutter Deck Idler Pivots | 2 | 1 | 1 | 1 | Weekly |

7. | Pump Control Bearings | 2 | 2 | 2 | 2 | Weekly |

No. 4 (Idler Pivot)

Located Under Engine Deck

No. 5 (Clutch Arm Pivot)

Located Under Engine Deck

No. 4 & 6 (Idler Arm Pivots) Disassemble and grease once a month under a “No Load” Condition.

c)Lubricate pivot points with a spray penetrating lubricant as directed below.

SPRAY LUBRICANT CHART

PIVOT POINT | NO. OF | SERVICE | |

PLACES | INTERVAL | ||

| |||

1. PTO Lever | 1 | Weekly |

5.1.15Check spark plugs. Service Interval: 160 hrs.

a)Stop engine and wait for all moving parts to stop.

b)Remove spark plugs, check condition and adjust plug gap or replace with new plugs. See Engine Owner's Manual.

5.1.16Remove engine shrouds and clean cooling fins. Service Interval: See Engine Owner's Manual

- 30 -