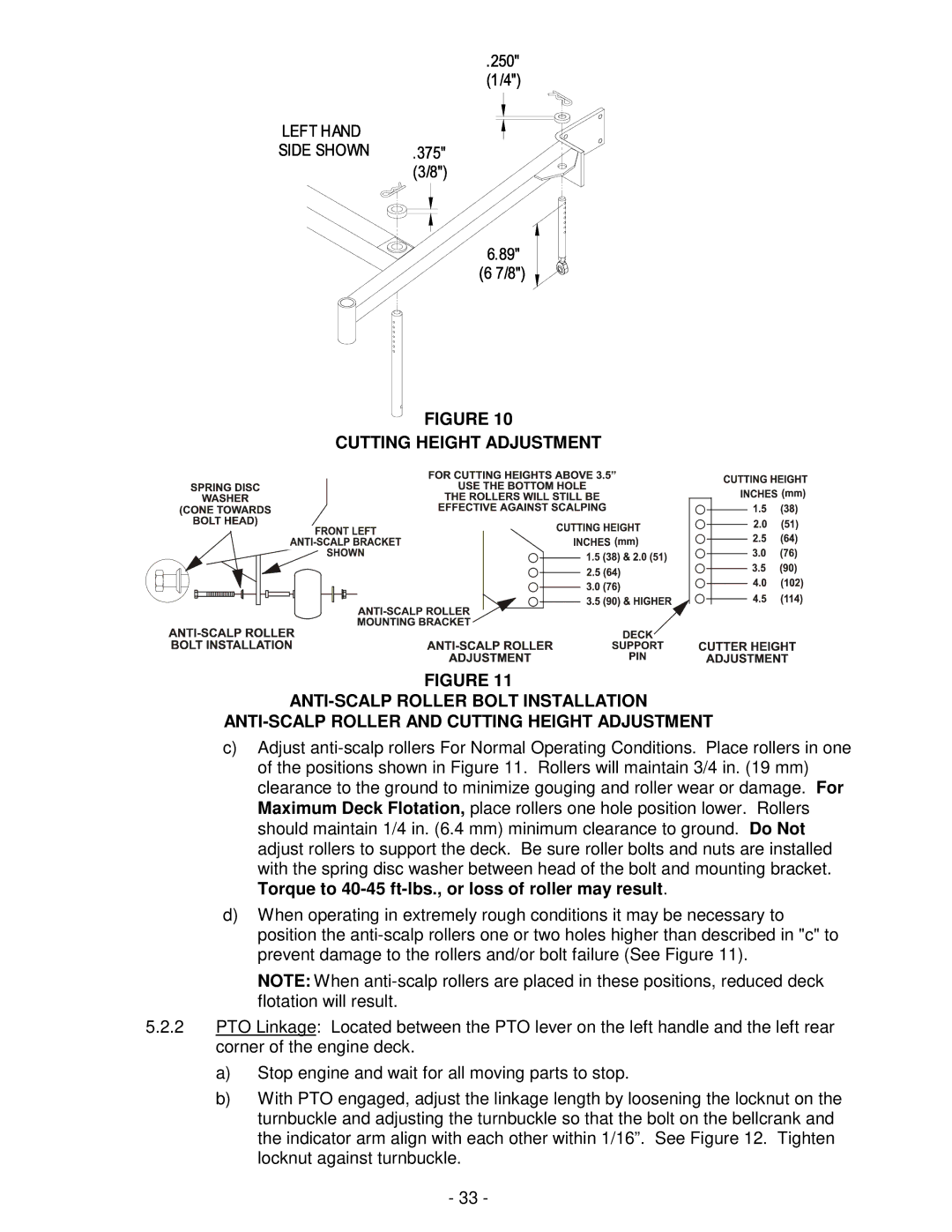

FIGURE 10

CUTTING HEIGHT ADJUSTMENT

FIGURE 11

ANTI-SCALP ROLLER BOLT INSTALLATION

ANTI-SCALP ROLLER AND CUTTING HEIGHT ADJUSTMENT

c)Adjust anti-scalp rollers For Normal Operating Conditions. Place rollers in one of the positions shown in Figure 11. Rollers will maintain 3/4 in. (19 mm) clearance to the ground to minimize gouging and roller wear or damage. For Maximum Deck Flotation, place rollers one hole position lower. Rollers should maintain 1/4 in. (6.4 mm) minimum clearance to ground. Do Not adjust rollers to support the deck. Be sure roller bolts and nuts are installed with the spring disc washer between head of the bolt and mounting bracket. Torque to 40-45ft-lbs., or loss of roller may result.

d)When operating in extremely rough conditions it may be necessary to position the anti-scalp rollers one or two holes higher than described in "c" to prevent damage to the rollers and/or bolt failure (See Figure 11).

NOTE: When anti-scalp rollers are placed in these positions, reduced deck flotation will result.

5.2.2PTO Linkage: Located between the PTO lever on the left handle and the left rear corner of the engine deck.

a)Stop engine and wait for all moving parts to stop.

b)With PTO engaged, adjust the linkage length by loosening the locknut on the turnbuckle and adjusting the turnbuckle so that the bolt on the bellcrank and the indicator arm align with each other within 1/16”. See Figure 12. Tighten locknut against turnbuckle.

-33 -