10

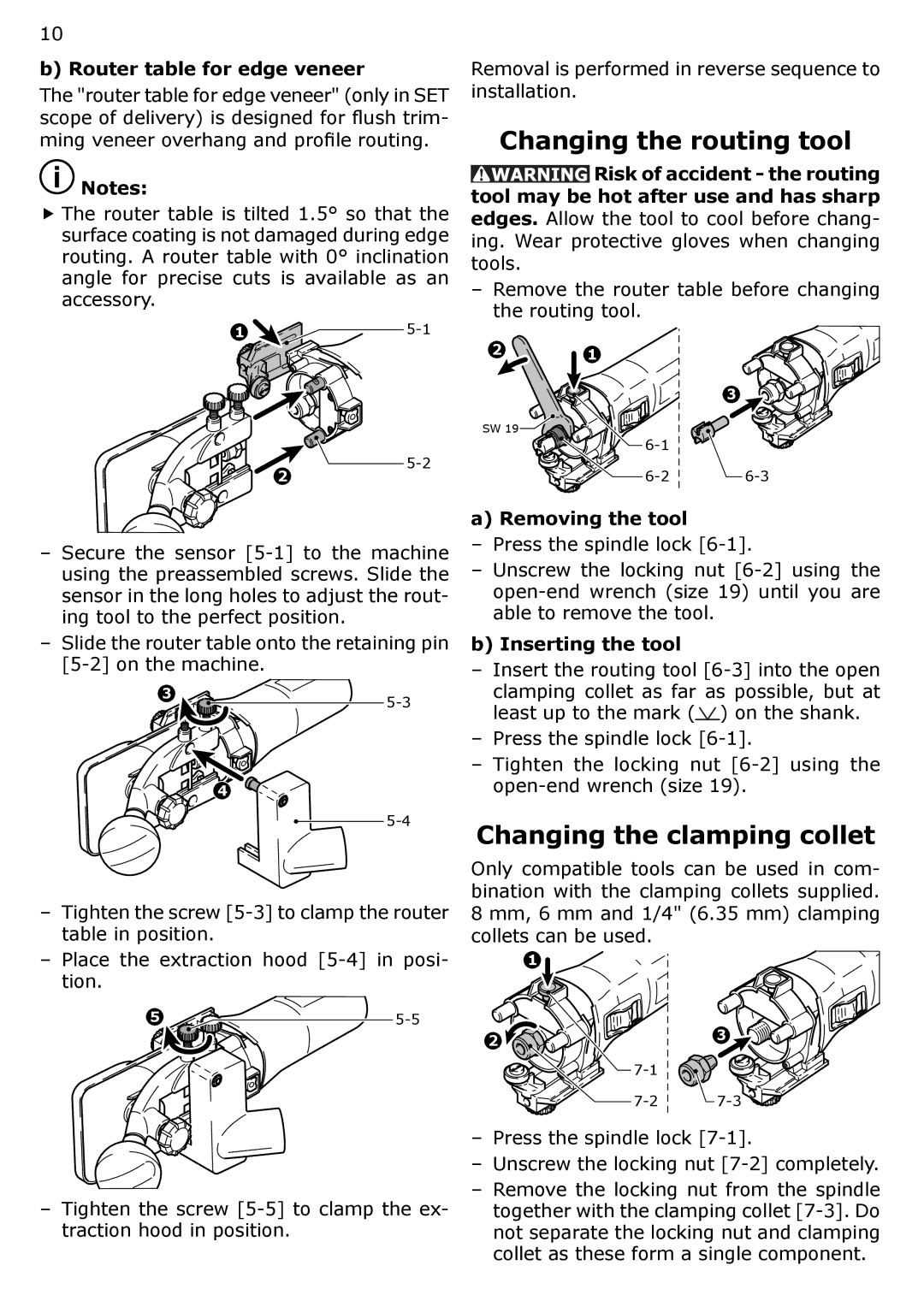

b) Router table for edge veneer

The "router table for edge veneer" (only in SET scope of delivery) is designed for flush trim- ming veneer overhang and profile routing.

![]() Notes:

Notes:

f The router table is tilted 1.5° so that the surface coating is not damaged during edge routing. A router table with 0° inclination angle for precise cuts is available as an accessory.

1 ![]() 5-1

5-1

Removal is performed in reverse sequence to installation.

Changing the routing tool

![]() Risk of accident - the routing tool may be hot after use and has sharp edges. Allow the tool to cool before chang-

Risk of accident - the routing tool may be hot after use and has sharp edges. Allow the tool to cool before chang-

ing. Wear protective gloves when changing tools.

–Remove the router table before changing the routing tool.

2 1

3

2

![]() 5-2

5-2

SW 19 |

a) Removing the tool

–Secure the sensor

–Slide the router table onto the retaining pin

3 | |

|

4

–Tighten the screw

–Place the extraction hood

5![]() 5-5

5-5

–Tighten the screw

–Press the spindle lock

–Unscrew the locking nut

b) Inserting the tool

–Insert the routing tool ![]() ) on the shank.

) on the shank.

–Press the spindle lock

–Tighten the locking nut

Changing the clamping collet

Only compatible tools can be used in com- bination with the clamping collets supplied. 8 mm, 6 mm and 1/4" (6.35 mm) clamping collets can be used.

1 |

|

2 | 3 |

| |

| |

–Press the spindle lock

–Unscrew the locking nut

–Remove the locking nut from the spindle together with the clamping collet