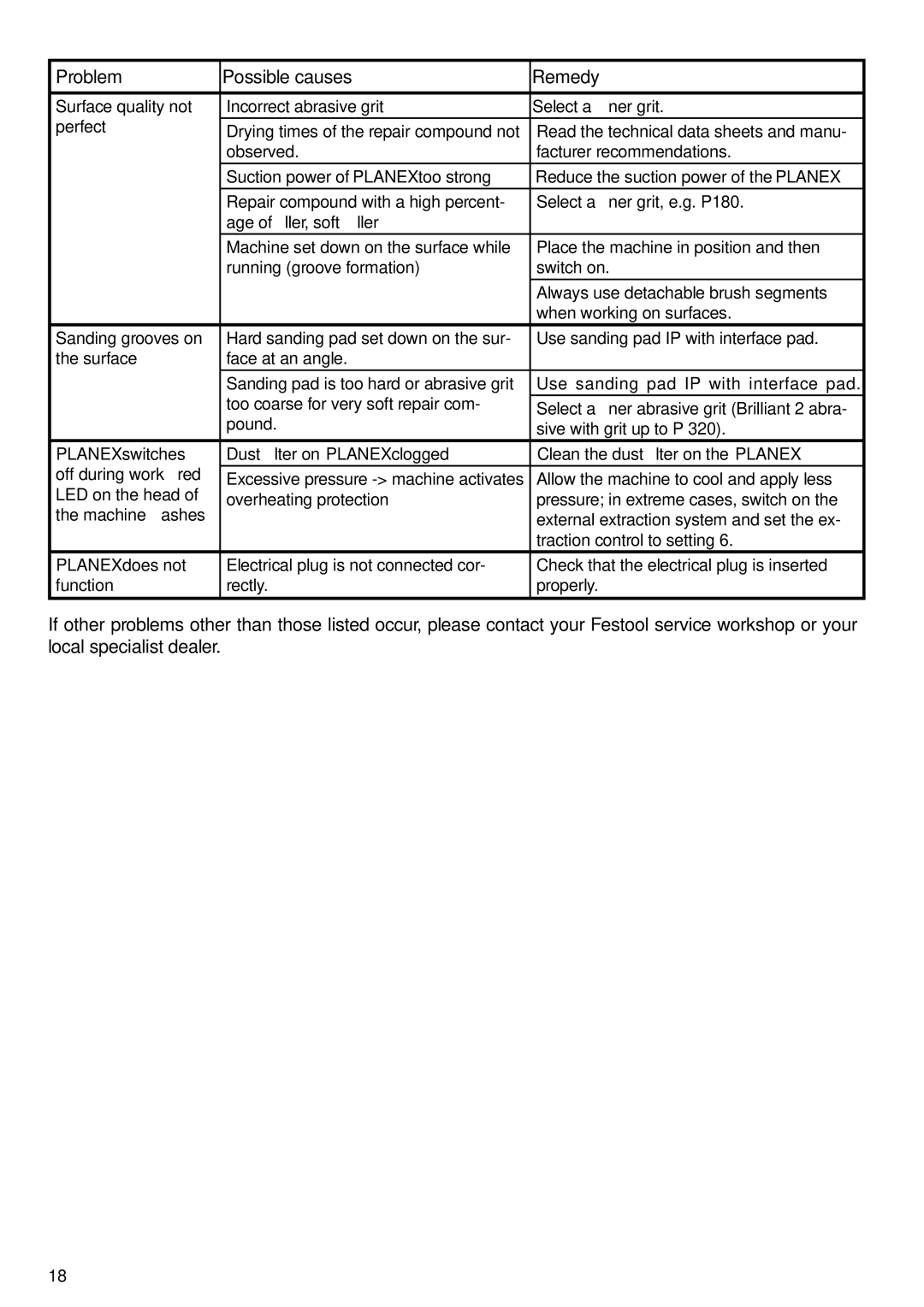

Problem | Possible causes | Remedy |

|

|

|

Surface quality not | Incorrect abrasive grit | Select a finer grit. |

perfect |

|

|

Drying times of the repair compound not | Read the technical data sheets and manu- | |

| observed. | facturer recommendations. |

| Suction power of PLANEX too strong | Reduce the suction power of the PLANEX |

| Repair compound with a high percent- | Select a finer grit, e.g. P180. |

| age of filler, soft filler |

|

| Machine set down on the surface while | Place the machine in position and then |

| running (groove formation) | switch on. |

|

| Always use detachable brush segments |

|

| when working on surfaces. |

Sanding grooves on | Hard sanding pad set down on the sur- | Use sanding pad IP with interface pad. |

the surface | face at an angle. |

|

| Sanding pad is too hard or abrasive grit | Use sanding pad IP with interface pad. |

| too coarse for very soft repair com- | Select a finer abrasive grit (Brilliant 2 abra- |

| pound. | sive with grit up to P 320). |

PLANEX switches | Dust filter on PLANEX clogged | Clean the dust filter on the PLANEX. |

off during work – red |

|

|

Excessive pressure | Allow the machine to cool and apply less | |

LED on the head of | overheating protection | pressure; in extreme cases, switch on the |

the machine flashes |

| external extraction system and set the ex- |

|

| traction control to setting 6. |

PLANEX does not | Electrical plug is not connected cor- | Check that the electrical plug is inserted |

function | rectly. | properly. |

If other problems other than those listed occur, please contact your Festool service workshop or your local specialist dealer.

18