FUNCTIONAL COMPONENT DEFINITIONS

MECHANICAL COMPONENTS

Bellows condensate valve

Vent door Allows introduction of fresh air into the room and/or exhausts stale room air outside (on select models.)

Plenum assembly Diffuser with directional louvers used to direct the conditioned airflow.

Blower wheel Attaches to the indoor side of the fan motor shaft and is used for distributing unconditioned, room side air though the heat exchanger and delivering conditioned air into the room.

ELECTRICAL COMPONENTS cont’d

MoneySaver® switch When engaged, it sends the power supply to the fan motor through the thermostat, which allows for a

Fan Motor

Solenoid Used to energize the reversing valve on all heat pump units.

Heating element Electric resistance heater, available in 3.3, 4.0 or 5.2 kW on select TwinTemp® models.

Heat anticipator Used to provide better thermostat and room air temperature control.

Slinger fan blade Attaches to the outdoor side of the fan motor shaft and is used to move outside air through the condenser coil, while slinging condensate water out of the base pan and onto the condenser coil, thus lowering the temperature and pressures within the coil.

ELECTRICAL COMPONENTS

Thermostat Used to maintain the specified room side comfort level

System switch Used to regulate the operation of the fan motor, the compressor or to turn the unit off. For troubleshoot- ing, refer to the wiring diagrams and schematics in the back of this service manual.

Capacitor Reduces line current and steadies the voltage supply, while greatly improving the torque characteristics of the fan motor and compressor motor.

HERMETIC COMPONENTS

Compressor Motorized device used to compress refrigerant through the sealed system.

Reversing valve A

Check valve A

Capillary tube A cylindrical meter device used to evenly dis- tribute the flow of refrigerant to the heat exchangers (coils.)

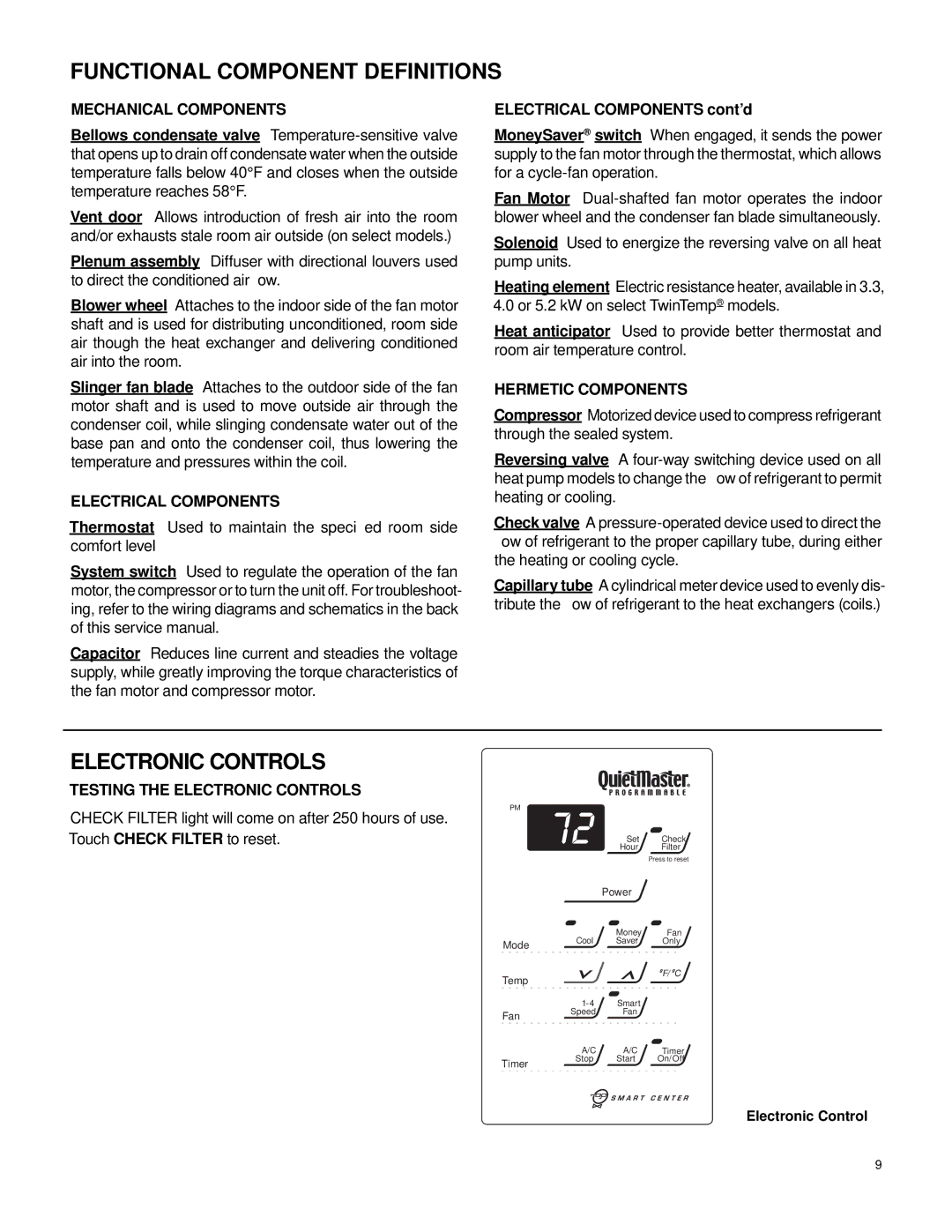

ELECTRONIC CONTROLS

TESTING THE ELECTRONIC CONTROLS

CHECK FILTER light will come on after 250 hours of use. Touch CHECK FILTER to reset.

PM

Set Check

Hour Filter

Press to reset

|

| Power |

|

|

| Money | Fan |

Mode | Cool | Saver® | Only |

|

|

| |

Temp |

|

| OF/ OC |

|

|

| |

| Smart |

| |

Fan | Speed | Fan |

|

|

|

| |

| A/C | A/C | Timer |

Timer | Stop | Start | On/ Off |

|

|

|

Electronic Control

9