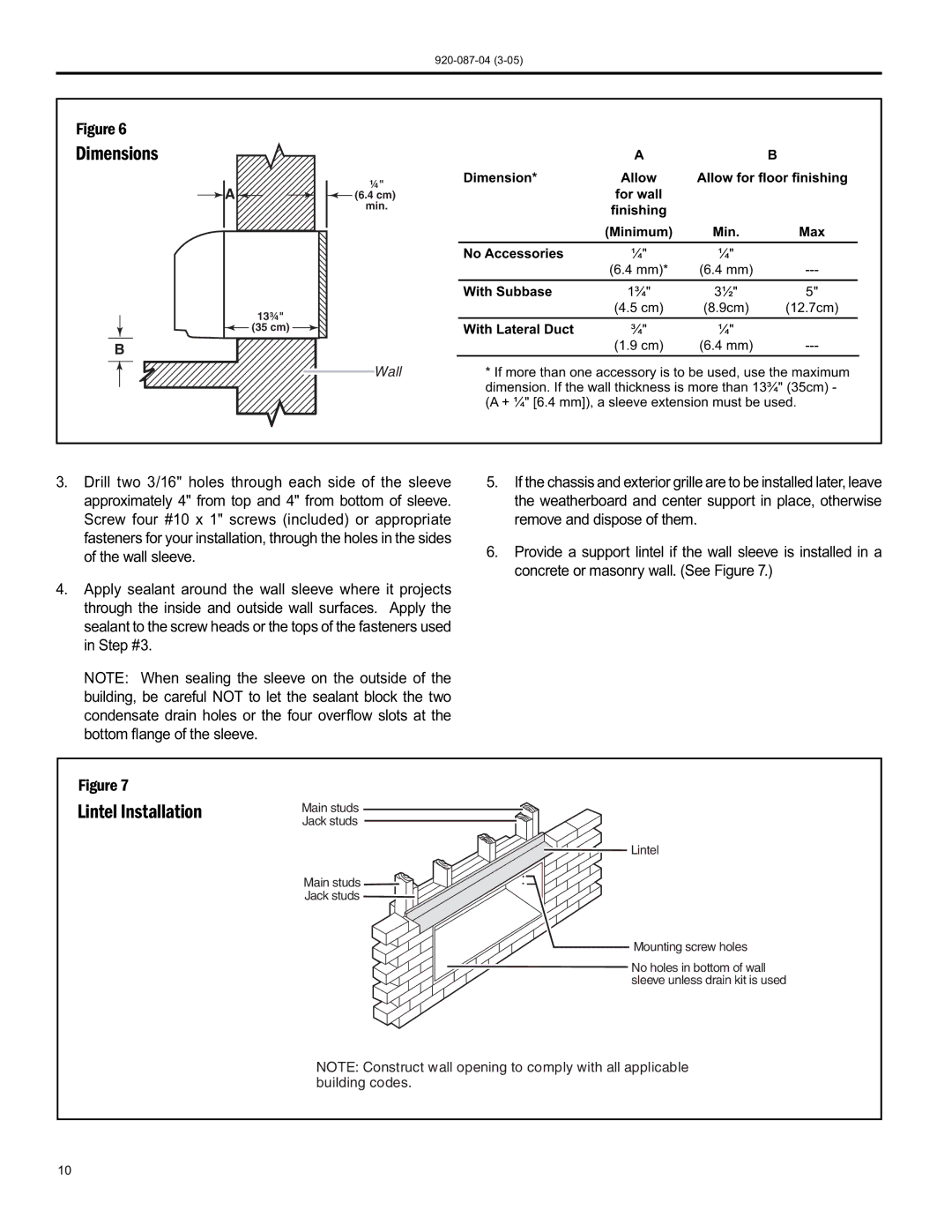

Figure6

Dimensions

¼"

![]() A

A ![]()

![]()

![]() (6.4 cm) min.

(6.4 cm) min.

13¾"

![]() (35 cm)

(35 cm) ![]()

B

Wall

| A |

| B |

Dimension* | Allow | Allow for floor finishing | |

| for wall |

|

|

| finishing |

|

|

| (Minimum) | Min. | Max |

No Accessories | ¼" | ¼" |

|

| (6.4 mm)* | (6.4 mm) | |

With Subbase | 1¾" | 3½" | 5" |

| (4.5 cm) | (8.9cm) | (12.7cm) |

With Lateral Duct | ¾" | ¼" |

|

| (1.9 cm) | (6.4 mm) | |

*If more than one accessory is to be used, use the maximum dimension. If the wall thickness is more than 13¾" (35cm) - (A + ¼" [6.4 mm]), a sleeve extension must be used.

3.Drill two 3/16" holes through each side of the sleeve approximately 4" from top and 4" from bottom of sleeve. Screw four #10 x 1" screws (included) or appropriate fasteners for your installation, through the holes in the sides of the wall sleeve.

4.Apply sealant around the wall sleeve where it projects through the inside and outside wall surfaces. Apply the sealant to the screw heads or the tops of the fasteners used in Step #3.

NOTE: When sealing the sleeve on the outside of the building, be careful NOT to let the sealant block the two condensate drain holes or the four overfl ow slots at the bottom flange of the sleeve.

5.If the chassis and exterior grille are to be installed later, leave the weatherboard and center support in place, otherwise remove and dispose of them.

6.Provide a support lintel if the wall sleeve is installed in a concrete or masonry wall. (See Figure 7.)

Figure7

LintelInstallation

Main studs

Jack studs

Lintel

Main studs

Jack studs

Mounting screw holes

No holes in bottom of wall sleeve unless drain kit is used

NOTE: Construct wall opening to comply with all applicable building codes.

10