ELECTRICAL INSTALLATION

ELECTRIC Dryer

![]()

![]()

![]()

![]()

![]()

![]()

![]() The following are specific requirements for proper and safe electrical installation of your dryer. Failure to follow these instructions can create electrical shock and/ or a fire hazard.

The following are specific requirements for proper and safe electrical installation of your dryer. Failure to follow these instructions can create electrical shock and/ or a fire hazard.

![]()

![]()

![]()

![]()

![]()

![]()

![]() This appliance MUST be properly grounded. Electrical shock can result if the dryer is not properly grounded. Follow the instructions in this manual for proper grounding.

This appliance MUST be properly grounded. Electrical shock can result if the dryer is not properly grounded. Follow the instructions in this manual for proper grounding.

![]()

![]()

![]()

![]()

![]()

![]()

![]() Do not use an extension cord with this dryer. Some extension cords are not designed to withstand the amounts of electrical current this dryer utilizes and can melt, creating electrical shock and/or fire hazard. Locate the dryer within reach of the receptacle for the length power cord to be purchased, allowing some slack in the cord. Refer to the

Do not use an extension cord with this dryer. Some extension cords are not designed to withstand the amounts of electrical current this dryer utilizes and can melt, creating electrical shock and/or fire hazard. Locate the dryer within reach of the receptacle for the length power cord to be purchased, allowing some slack in the cord. Refer to the

![]()

![]()

![]()

![]()

![]()

![]()

![]() A U.L. approved strain relief must be installed onto power cord. If the strain relief is not attached, the cord can be pulled out of the dryer and can be cut by any movement of the cord, resulting in electrical shock.

A U.L. approved strain relief must be installed onto power cord. If the strain relief is not attached, the cord can be pulled out of the dryer and can be cut by any movement of the cord, resulting in electrical shock.

![]()

![]()

![]()

![]()

![]()

![]()

![]() Do not use an aluminum wired receptacle with a copper wired power cord and plug (or vice versa). A chemical reaction occurs between copper and aluminum and can cause electrical shorts. The proper wiring and receptacle is a copper wired power cord with a copper wired receptacle.

Do not use an aluminum wired receptacle with a copper wired power cord and plug (or vice versa). A chemical reaction occurs between copper and aluminum and can cause electrical shorts. The proper wiring and receptacle is a copper wired power cord with a copper wired receptacle.

NOTE: Dryers operating on 208 volt power supply will have longer drying times than operating on 240 volt power supply.

GROUNDING REQUIREMENTS

USA ELECTRIC Dryer

![]()

![]()

![]()

![]()

![]() Improper connection of the equipment grounding conductor can result in a risk of electrical shock. Check with a licensed electrician if you are in doubt as to whether the appliance is properly grounded.

Improper connection of the equipment grounding conductor can result in a risk of electrical shock. Check with a licensed electrician if you are in doubt as to whether the appliance is properly grounded.

For a grounded, cord-connected dryer:

1.The dryer MUST be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electrical shock by a path of least resistance for electrical current.

2.If your dryer is equipped with a power supply cord having an

For a permanently connected dryer:

1.The dryer MUST be connected to a grounded metal, permanent wiring system; or an equipment grounding conductor must be run with the circuit conductors and connected to the

Canadian ELECTRIC Dryer

DANGER Improper connection of the equipment grounding conductor can result in a risk of electrical shock. Check with a licensed electrician if you are in doubt as to whether the appliance is properly grounded.

For a grounded,

1.The dryer must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electrical shock by a path of least resistance for electrical current.

2.Since your dryer is equipped with a power supply cord having an

ALL GAS Dryers

1.The dryer is equipped with a

GAS CONNECTION

1.Remove the shipping cap from gas pipe at the rear of the dryer.

NOTE: DO NOT connect the dryer to L.P. gas service without converting the gas valve. An L.P. conversion kit must be installed by a qualified gas technician.

2.Connect a 1/2 inch (1.27 cm) I.D.

3.Open the shutoff valve in the gas supply line to allow gas to flow through pipe.

4.Test all connections by brushing on a soapy water solution.

NEVER test for gas leaks with an open flame.

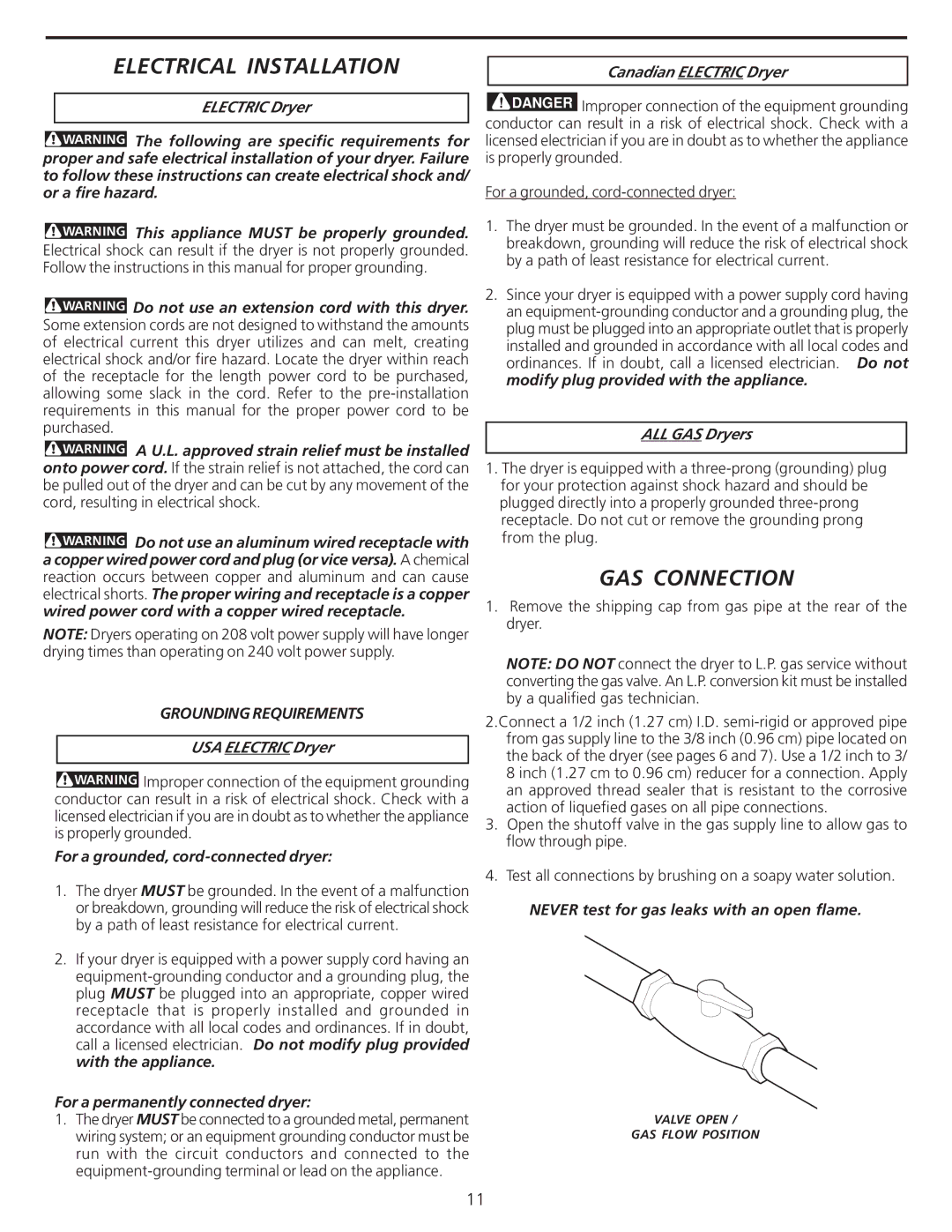

VALVE OPEN /

GAS FLOW POSITION

11