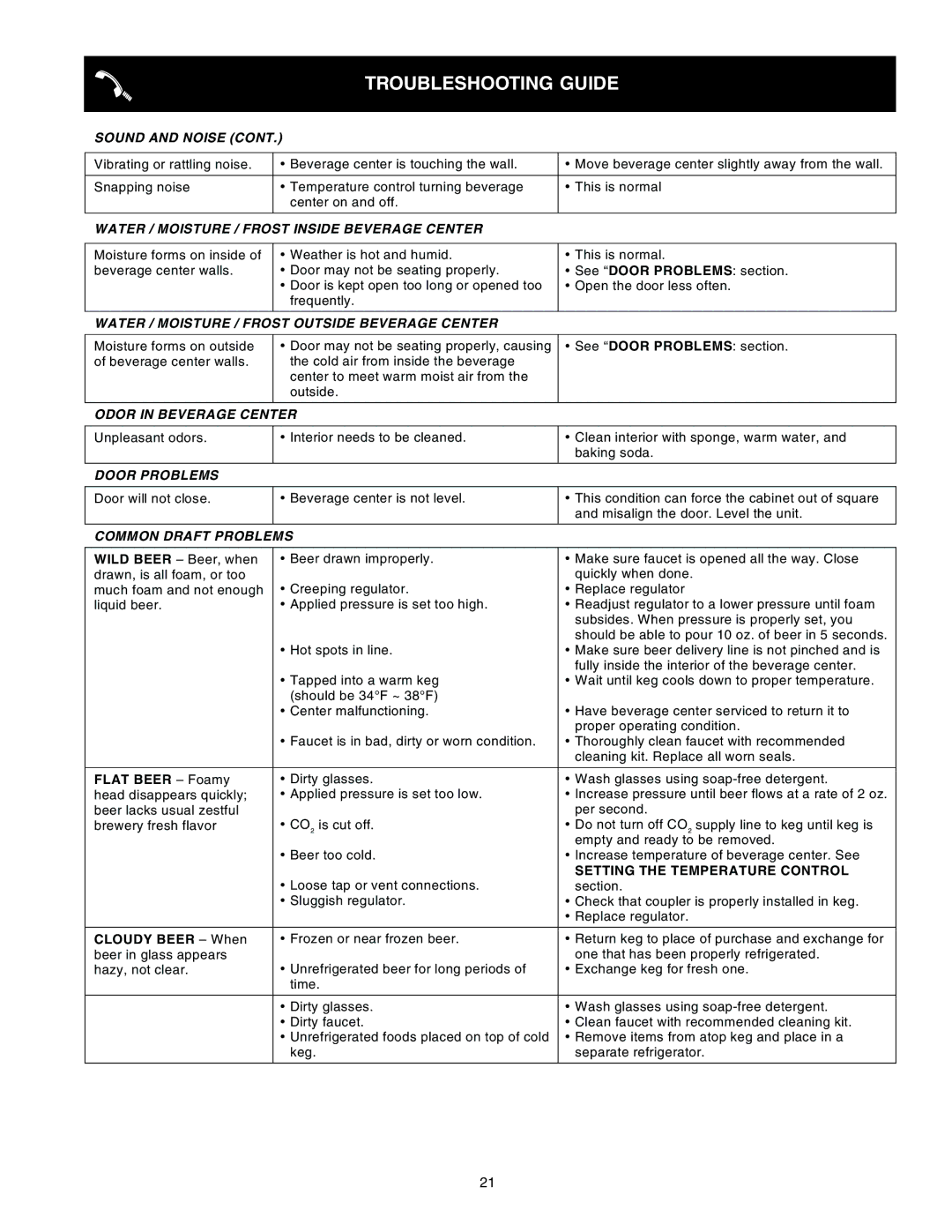

TROUBLESHOOTING GUIDE

SOUND AND NOISE (CONT.)

Vibrating or rattling noise. | • Beverage center is touching the wall. | • Move beverage center slightly away from the wall. | |

|

|

| |

Snapping noise | • Temperature control turning beverage | • This is normal | |

| center on and off. |

| |

|

|

| |

WATER / MOISTURE / FROST INSIDE BEVERAGE CENTER |

| ||

Moisture forms on inside of beverage center walls.

•Weather is hot and humid.

•Door may not be seating properly.

•Door is kept open too long or opened too frequently.

•This is normal.

•See “DOOR PROBLEMS: section.

•Open the door less often.

WATER / MOISTURE / FROST OUTSIDE BEVERAGE CENTER

Moisture forms on outside of beverage center walls.

•Door may not be seating properly, causing the cold air from inside the beverage center to meet warm moist air from the outside.

•See “DOOR PROBLEMS: section.

ODOR IN BEVERAGE CENTER

Unpleasant odors. | • Interior needs to be cleaned. | |

|

|

DOOR PROBLEMS

•Clean interior with sponge, warm water, and baking soda.

Door will not close.

•Beverage center is not level.

•This condition can force the cabinet out of square and misalign the door. Level the unit.

COMMON DRAFT PROBLEMS |

| |

WILD BEER – Beer, when | • Beer drawn improperly. | • Make sure faucet is opened all the way. Close |

drawn, is all foam, or too |

| quickly when done. |

much foam and not enough | • Creeping regulator. | • Replace regulator |

liquid beer. | • Applied pressure is set too high. | • Readjust regulator to a lower pressure until foam |

|

| subsides. When pressure is properly set, you |

|

| should be able to pour 10 oz. of beer in 5 seconds. |

| • Hot spots in line. | • Make sure beer delivery line is not pinched and is |

|

| fully inside the interior of the beverage center. |

| • Tapped into a warm keg | • Wait until keg cools down to proper temperature. |

| (should be 34°F ~ 38°F) |

|

| • Center malfunctioning. | • Have beverage center serviced to return it to |

|

| proper operating condition. |

| • Faucet is in bad, dirty or worn condition. | • Thoroughly clean faucet with recommended |

|

| cleaning kit. Replace all worn seals. |

|

|

|

FLAT BEER – Foamy | • Dirty glasses. | • Wash glasses using |

head disappears quickly; | • Applied pressure is set too low. | • Increase pressure until beer flows at a rate of 2 oz. |

beer lacks usual zestful |

| per second. |

brewery fresh flavor | • CO2 is cut off. | • Do not turn off CO2 supply line to keg until keg is |

|

| empty and ready to be removed. |

| • Beer too cold. | • Increase temperature of beverage center. See |

| • Loose tap or vent connections. | SETTING THE TEMPERATURE CONTROL |

| section. | |

| • Sluggish regulator. | • Check that coupler is properly installed in keg. |

|

| • Replace regulator. |

|

|

|

CLOUDY BEER – When | • Frozen or near frozen beer. | • Return keg to place of purchase and exchange for |

beer in glass appears |

| one that has been properly refrigerated. |

hazy, not clear. | • Unrefrigerated beer for long periods of | • Exchange keg for fresh one. |

| time. |

|

|

|

|

| • Dirty glasses. | • Wash glasses using |

| • Dirty faucet. | • Clean faucet with recommended cleaning kit. |

| • Unrefrigerated foods placed on top of cold | • Remove items from atop keg and place in a |

| keg. | separate refrigerator. |

|

|

|

21