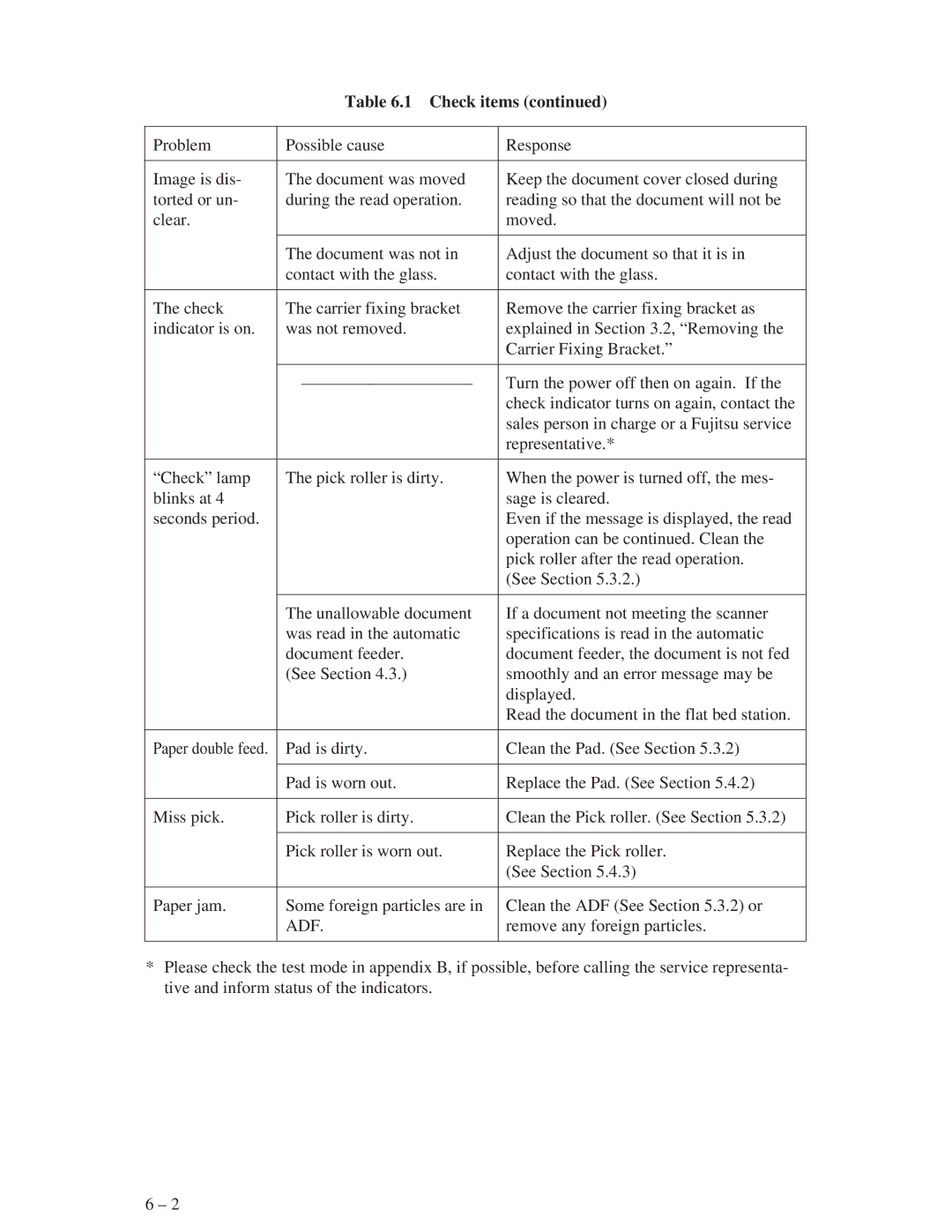

Table 6.1 Check items (continued)

Problem | Possible cause | Response |

|

|

|

Image is dis- | The document was moved | Keep the document cover closed during |

torted or un- | during the read operation. | reading so that the document will not be |

clear. |

| moved. |

|

|

|

| The document was not in | Adjust the document so that it is in |

| contact with the glass. | contact with the glass. |

|

|

|

The check | The carrier fixing bracket | Remove the carrier fixing bracket as |

indicator is on. | was not removed. | explained in Section 3.2, “Removing the |

|

| Carrier Fixing Bracket.” |

|

|

|

| Turn the power off then on again. If the | |

|

| check indicator turns on again, contact the |

|

| sales person in charge or a Fujitsu service |

|

| representative.* |

|

|

|

“Check” lamp | The pick roller is dirty. | When the power is turned off, the mes- |

blinks at 4 |

| sage is cleared. |

seconds period. |

| Even if the message is displayed, the read |

|

| operation can be continued. Clean the |

|

| pick roller after the read operation. |

|

| (See Section 5.3.2.) |

|

|

|

| The unallowable document | If a document not meeting the scanner |

| was read in the automatic | specifications is read in the automatic |

| document feeder. | document feeder, the document is not fed |

| (See Section 4.3.) | smoothly and an error message may be |

|

| displayed. |

|

| Read the document in the flat bed station. |

|

|

|

Paper double feed. | Pad is dirty. | Clean the Pad. (See Section 5.3.2) |

|

|

|

| Pad is worn out. | Replace the Pad. (See Section 5.4.2) |

|

|

|

Miss pick. | Pick roller is dirty. | Clean the Pick roller. (See Section 5.3.2) |

|

|

|

| Pick roller is worn out. | Replace the Pick roller. |

|

| (See Section 5.4.3) |

|

|

|

Paper jam. | Some foreign particles are in | Clean the ADF (See Section 5.3.2) or |

| ADF. | remove any foreign particles. |

|

|

|

*Please check the test mode in appendix B, if possible, before calling the service representa- tive and inform status of the indicators.

6 – 2