USP 13 Universal Speed Punch

Operating Instructions

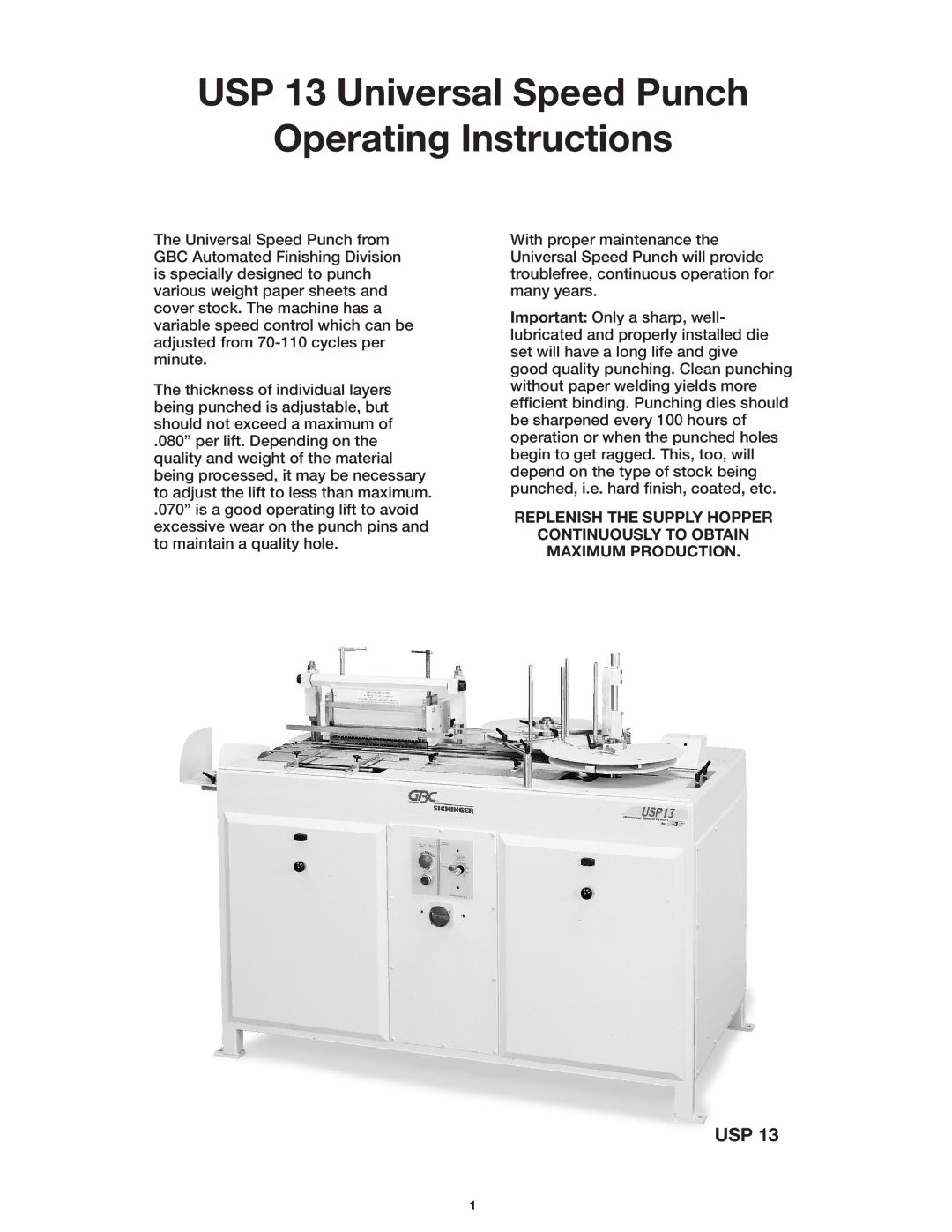

The Universal Speed Punch from GBC Automated Finishing Division is specially designed to punch various weight paper sheets and cover stock. The machine has a variable speed control which can be adjusted from

The thickness of individual layers being punched is adjustable, but should not exceed a maximum of

.080” per lift. Depending on the quality and weight of the material being processed, it may be necessary to adjust the lift to less than maximum.

.070” is a good operating lift to avoid excessive wear on the punch pins and to maintain a quality hole.

With proper maintenance the Universal Speed Punch will provide troublefree, continuous operation for many years.

Important: Only a sharp, well- lubricated and properly installed die set will have a long life and give good quality punching. Clean punching without paper welding yields more efficient binding. Punching dies should be sharpened every 100 hours of operation or when the punched holes begin to get ragged. This, too, will depend on the type of stock being punched, i.e. hard finish, coated, etc.

REPLENISH THE SUPPLY HOPPER

CONTINUOUSLY TO OBTAIN MAXIMUM PRODUCTION.

USP 13

1