Section 3 —

Guardian

3.7ENGINE GOVERNOR ADJUSTMENT

If both AC frequency and voltage are correspondingly high or low, adjust the engine governor as follows:

◆3.7.1 6 KW UNITS (NON-SA)

1.Loosen the governor clamp bolt (Figure 3.1).

2.Push the spring end of the governor lever clock- wise to the wide open throttle position of the lever.

•Hold the governor lever at wide open throttle and, with a pair of pliers, rotate the governor shaft fully clockwise.

•While holding the governor shaft fully clockwise and the governor lever at wide open throttle, tighten the governor clamp bolt to 70 inch- pounds (8

3.Start the engine; let it stabilize and warm up at

4.Turn the adjuster nut to obtain a frequency read- ing of 62 Hertz.

5.Determine if the governor spring is properly located in the slot of the governor lever as follows:

•If droop is excessive, move the governor spring down one slot on the lever.

•For greater stability, move the governor spring up one slot on the lever.

6.After repositioning the spring on a lever slot, recheck the frequency reading and, if necessary, readjust the adjuster nut to obtain 62 Hertz at

7.When frequency is correct at

Figure 3.1 – 6 kW

Engine Governor Adjustment

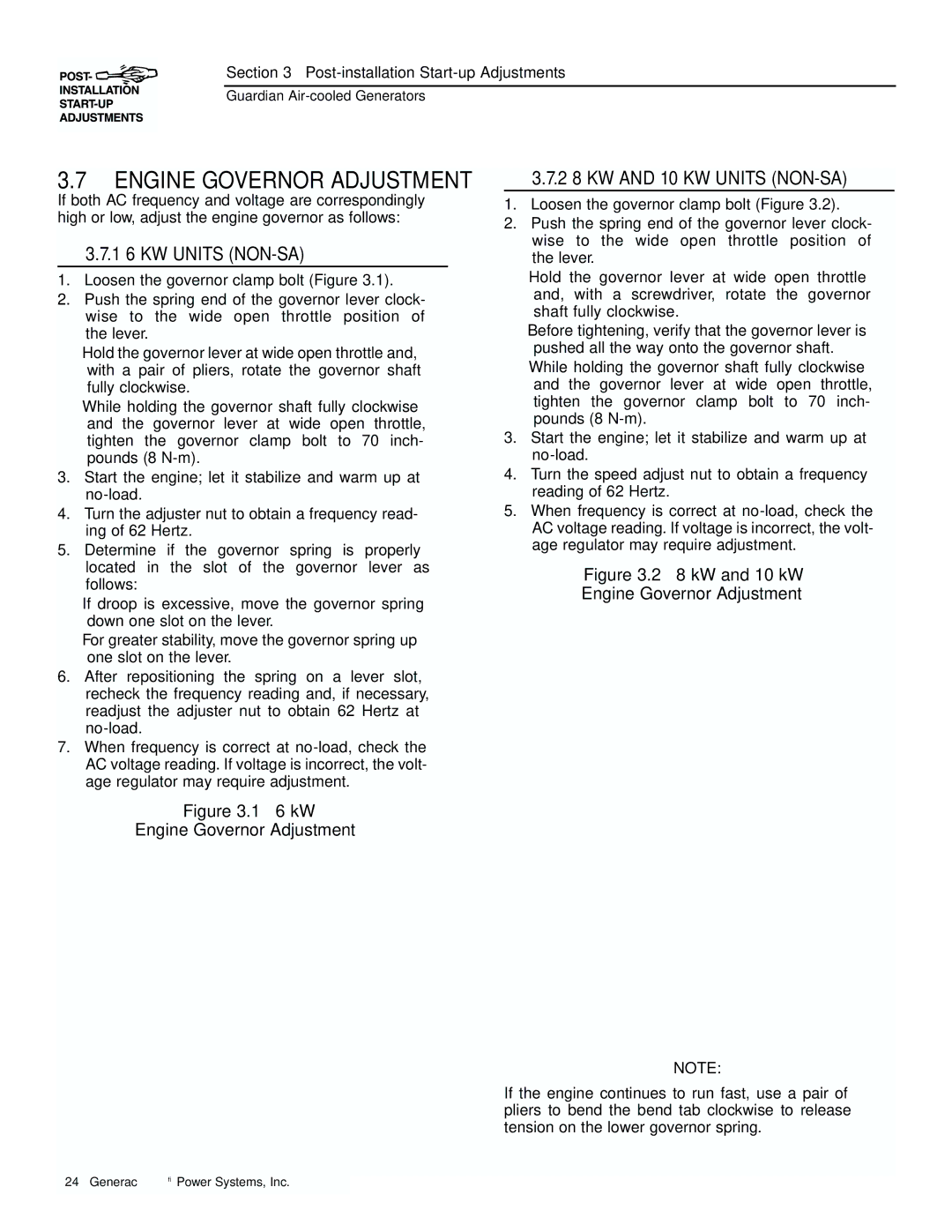

◆3.7.2 8 KW AND 10 KW UNITS (NON-SA)

1.Loosen the governor clamp bolt (Figure 3.2).

2.Push the spring end of the governor lever clock- wise to the wide open throttle position of the lever.

•Hold the governor lever at wide open throttle and, with a screwdriver, rotate the governor shaft fully clockwise.

•Before tightening, verify that the governor lever is pushed all the way onto the governor shaft.

•While holding the governor shaft fully clockwise and the governor lever at wide open throttle, tighten the governor clamp bolt to 70 inch- pounds (8

3.Start the engine; let it stabilize and warm up at

4.Turn the speed adjust nut to obtain a frequency reading of 62 Hertz.

5.When frequency is correct at

Figure 3.2 – 8 kW and 10 kW

Engine Governor Adjustment

NOTE:

If the engine continues to run fast, use a pair of pliers to bend the bend tab clockwise to release tension on the lower governor spring.

24 Generac® Power Systems, Inc.