Section 1 — General Information

Guardian

1.10.2 GENERATOR

|

|

| |||

| Model |

| |||

| Rated Max. Cont. | *25 | 20 | 15 |

|

| AC Power Output (kW) |

|

|

|

|

| Rated voltage (volts) |

| 120/240 | 120/240 |

|

| No. of Rotor Poles | 4 | 4 | 4 |

|

| Driven Speed of Rotor | 1800 | 1800 | 1800 |

|

| Rotor Excitation System | Direct excited brush type | Direct excited brush type | Direct excited brush type |

|

| Type of Stator | 4 Wire | 4 Wire | 4 Wire |

|

| Rotor Insulation | Class F | Class F | Class F |

|

| Stator Insulation | Class H | Class H | Class H |

|

|

|

|

|

|

|

*Rated power of generator is subject to and limited by such factors as ambient temperature, altitude, engine condition, and other factors. Engine power will decrease about 3.5% for each 1000 feet above sea level and will decrease an addi- tional 1% for each 10°F above 60°F. Maximum output power of the generator is limited by maximum engine power.

1.11 FUEL CONSUMPTION

25 kW Models

Using Natural Gas | ........................................441 cu. ft. per hour |

Using LP Gas | 175 cubic ft.(4.8 gal.) per hour |

Fuel pressure for a natural gas set up should be five inches to 14 inches of water column (0.18 to 0.5 psi) at all load ranges.

Fuel pressure for an LP vapor set up should be 11 inches to 14 inches of water column (0.4 to 0.5 psi) at all load ranges.

NOTE:

Fuel consumption is given at rated maximum con- tinuous power output when using natural gas rated at 1000 Btu per cubic foot; or LP gas rated 2520 Btu per cubic foot. Actual fuel consumption obtained may vary depending on such variables as applied load, ambient temperature, engine condi- tions and other environmental factors.

5.Install brass hose fitting into Port 2.

6.Install pipe plug into Port 1.

7.Connect carburetor gas hose to brass fitting.

8.Tighten all clamps and plugs.

9.Make sure fuel supply is of the proper pressure and type for configuration.

10.Move dip switch position 4 on the control board to the off position (LP vapor, see Figure 3.2 and Section 3.8).

11.Reverse the procedure to convert back to natural gas.

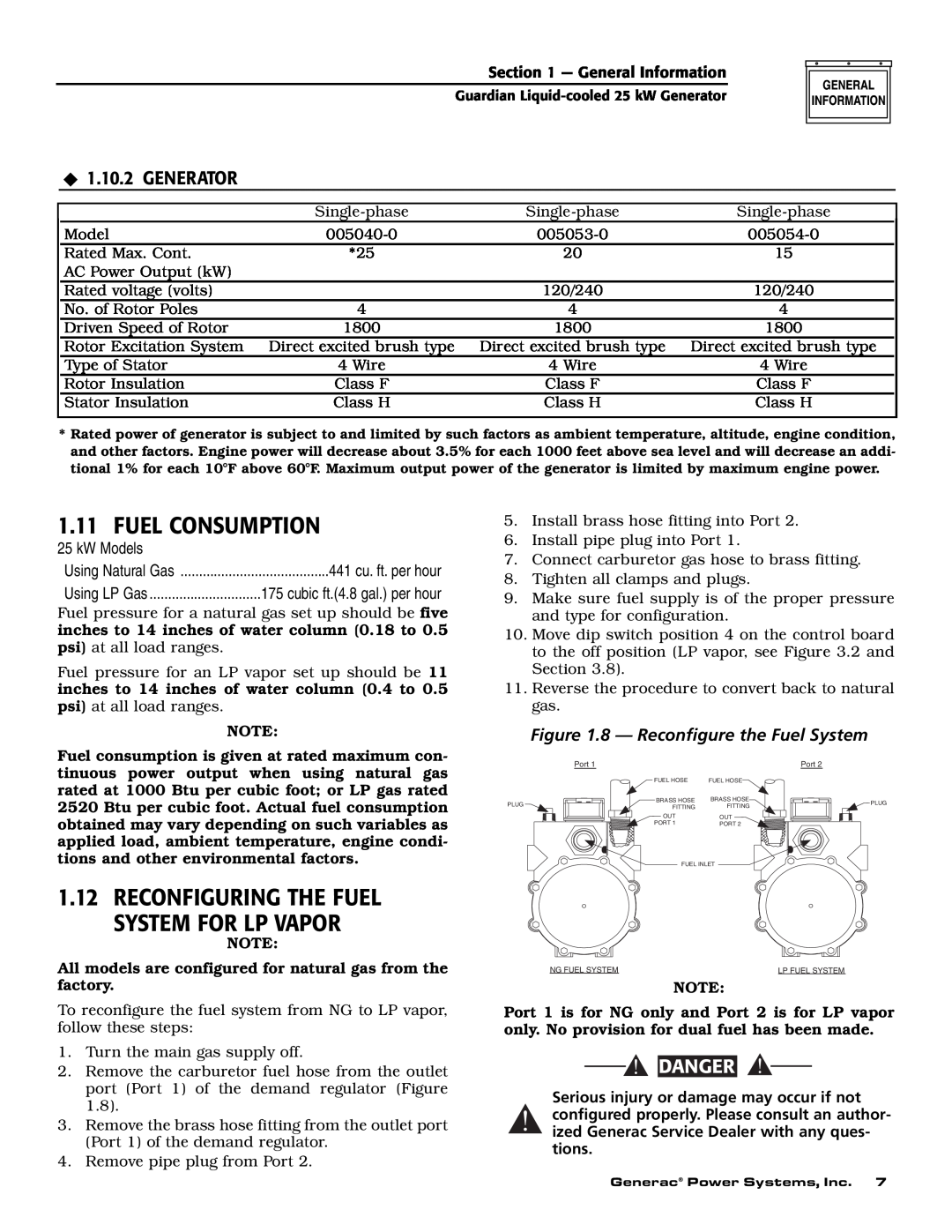

Figure 1.8 — Reconfigure the Fuel System

| Port 1 |

| Port 2 | |

| FUEL HOSE | FUEL HOSE |

| |

PLUG | BRASS HOSE | BRASS HOSE | PLUG | |

FITTING | FITTING | |||

| ||||

| OUT | OUT |

| |

| PORT 1 | PORT 2 |

|

FUEL INLET

1.12RECONFIGURING THE FUEL SYSTEM FOR LP VAPOR

NOTE:

All models are configured for natural gas from the factory.

To reconfigure the fuel system from NG to LP vapor, follow these steps:

1.Turn the main gas supply off.

2.Remove the carburetor fuel hose from the outlet port (Port 1) of the demand regulator (Figure 1.8).

3.Remove the brass hose fitting from the outlet port (Port 1) of the demand regulator.

4.Remove pipe plug from Port 2.

NG FUEL SYSTEM | LP FUEL SYSTEM |

NOTE:

Port 1 is for NG only and Port 2 is for LP vapor only. No provision for dual fuel has been made.

![]()

![]() DANGER

DANGER

!configured properly. Please consult an author- ized Generac Service Dealer with any ques- tions.

Generac® Power Systems, Inc. 7