Liquid-cooled, Prepackaged Standby Generators

SHOULD ATTEMPT INSTALLATION

Owner’s Manual

This manual should remain with the unit

‹ HOW TO OBTAIN SERVICE

AUTHORIZED SERVICE DEALER LOCATION

‹ OPERATION AND MAINTENANCE

INTRODUCTION

Table of Contents

Guardian Liquid-cooled 25 kW Generator

Parts of the generator are rotating and/or hot

GENERAL HAZARDS

Despite the safe design of this generator

during operation. Exercise care near running gen- erators

EXPLOSION HAZARDS

ELECTRICAL HAZARDS

FIRE HAZARDS

‹ STANDARDS INDEX

1.3 AUTOMATIC SYSTEM OPERATION

1.2 TRANSFER SWITCH

1.1 GENERATOR

1.4 GENERATOR AC CONNECTION SYSTEMS

‹ 1.7.3 LOW COOLANT LEVEL SWITCH

‹ 1.7.1 LOW OIL PRESSURE SWITCH

‹ 1.7.2 HIGH COOLANT TEMPERATURE SWITCH

Figure 1.4 - Low Oil Pressure Switch

‹ 1.8.1 UNPACKING PRECAUTIONS

1.10 SPECIFICATIONS

‹ 1.7.6 LOW BATTERY

1.8 UNPACKING

1.11 FUEL CONSUMPTION

1.12 RECONFIGURING THE FUEL SYSTEM FOR LP VAPOR

Figure 1.8 - Reconfigure the Fuel System

‹ 1.10.2 GENERATOR

1.13 ENGINE OIL RECOMMENDATIONS

1.15 BEFORE INSTALLATION

2.1 STANDBY GENERATOR INSTALLATION

1.14 COOLANT RECOMMENDATIONS

2.2 GENERATOR LOCATION

2.3 GENERATOR MOUNTING AND SUPPORT

2.4 BASIC STANDBY ELECTRIC SYSTEM

‹ 2.1.2 OTHER PUBLISHED STANDARDS

2.6 TOTAL CIRCUIT ISOLATION METHOD

2.9 USING AN ENGINEERED “GTS” TRANSFER SWITCH

2.5 EMERGENCY CIRCUIT ISOLATION METHOD

2.7 GROUNDING THE GENERATOR

‹ 2.10.1 VENTED BATTERIES

2.10 BATTERY INSTALLATION

Pos2 OFF - Standard Prepackaged ATS Application

Standby generators installed with automatic

2.11 PREPARATION BEFORE START-UP

3.1 ENGINEERED GTS TRANSFER SWITCH

‹ 2.11.2 TRANSFER SWITCH

‹ 2.11.1 PRIOR TO INITIAL START-UP

‹ 3.2.5 SET EXERCISE TIME SWITCH

‹ 3.2.2 FAULT INDICATOR LEDS

‹ 3.2.1 AUTO/OFF/MANUAL SWITCH

3.2 CONTROL CONSOLE COMPONENTS

‹ 3.2.6 SYSTEM READY LED

3.4 ENGINE GOVERNOR ADJUSTMENTS

3.3 MANUAL TRANSFER AND START-UP

3.6 AUTOMATIC OPERATION

Figure 3.2 - Engine Governor Adjustment

Figure 3.3 - “Set Exercise Time” Switch

3.7 WEEKLY EXERCISE CYCLE

A. EVERY THREE MONTHS

3.8 CONTROL BOARD DIP SWITCH SETTINGS

4.1 MAINTENANCE PERFORMED BY AUTHORIZED SERVICE FACILITIES

B. ONCE EVERY SIX MONTHS

4.4 CYLINDER HEAD PROCEDURE

4.2 EXHAUST MANIFOLD PROCEDURE

4.3 INTAKE MANIFOLD PROCEDURE

Figure 4.1 - Intake Manifold Installation

4.7 CHECKING FLUID LEVELS

4.8 MAINTENANCE OWNER/ OPERATOR CAN PERFORM

4.6 OVERLOAD PROTECTION FOR ENGINE DC ELECTRICAL SYSTEM

‹ 4.8.8 CHECK FAN BELT

‹ 4.8.11 CHANGING THE ENGINE AIR CLEANER

Figure 4.4 - Setting the Spark Plug Gap

‹ 4.8.9 INSPECT ENGINE GOVERNOR

‹ 4.9.2 BATTERY

4.9 MISCELLANEOUS MAINTENANCE

‹ 4.9.1 CLEANING THE GENERATOR

‹ 4.9.3 BATTERY MAINTENANCE

Turn off the battery charger turn OFF utility supply to ATS

4.10 SCHEDULED MAINTENANCE

Service Maintenance Interval Information

Remove the negative battery cable

Tasks

Maintenance

Level

Maintenance

CAUSE

TROUBLESHOOTING POINTS

PROBLEM

CORRECTION

Generac Power Systems, Inc

Section 7 - Electrical Data

Wiring Diagram - 2.5L Engine 15kW & 20kW units -Drawing No. 0F1411

26 Generac Power Systems, Inc

Generac Power Systems, Inc

28 Generac Power Systems, Inc

Generac Power Systems, Inc

Wiring Diagram - 2.5L Engine 25kW unit -Drawing No. 0E9982-B

30 Generac Power Systems, Inc

Generac Power Systems, Inc

Electrical Schematic - 2.5L 25kW unit - Drawing No. 0E9983-B

32 Generac Power Systems, Inc

Generac Power Systems, Inc

MOUNT

HARNESS WIRE

34 Generac Power Systems, Inc

BLOCK ENGINE

DESCRIPTION

COVER CABLE

PANEL FOR ACCESS

GROUND WIRE

FASTENER TO SECURE

Enclosure - Drawing No. 0E9720-D

38 Generac Power Systems, Inc

HINGE CONTINUOUS 1.5L CTRL PNL

40 Generac Power Systems, Inc

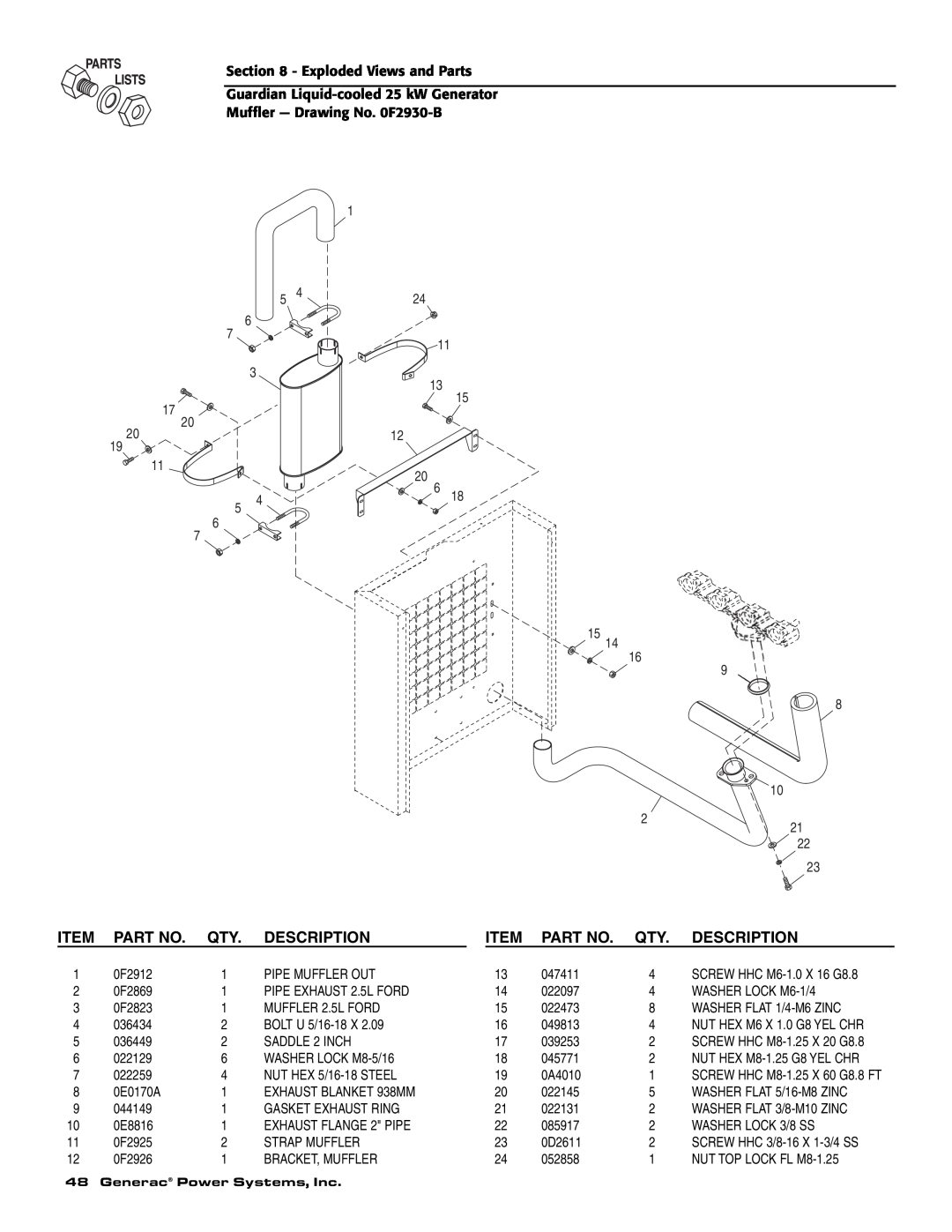

Section 8 - Exploded Views and Parts

STEPPER MOTOR UNITS ONLY

42 Generac Power Systems, Inc

Guardian Liquid-cooled 25 kW Generator Engine - Drawing No. 0E9918-E

TO RADIATOR

SERPENTINE BELT - 41 3/8 LENGTH

SOURCE GENERAC-BOSCH GOV

GASKET, 2.5L FORD EXHAUST MAN

BRKT,D.C. ALTERNATORMACHINED

COVER

0E1028A I/N

TO ENGINE

44 Generac Power Systems, Inc

Guardian Liquid-cooled 25 kW Generator

46 Generac Power Systems, Inc

LOCKTIGHT

LEADS

Alternator - Drawing No. 0E8660-C

STR 390 35AD1 HSB 382MM LONG3.0L FORD & 2.5L FORD

ROTOR REPLACEMENT PARTS

ROTOR 390 30KW 1P DIRECT HSB 3.0L FORD & 2.5L FORD

CONDUIT FLEX 1-1/4 30 LG - 3.0L FORD & 3.9L CHRYSLER

48 Generac Power Systems, Inc

SCREW HHC M8-1.25 X 60 G8.8 FT

COATING

SECURE WIRE HARNESS

ITEM 13 NEOPRENE

WITH TIE WRAP AS SHOWN

SUPPORT,RADIATOR 2.5L FORD

50 Generac Power Systems, Inc

1024

HOSE, UPPER RADIATOR 174MM

Section 9 - Installation Diagram

Installation Diagram - Drawing No. 0F1020-A

PURCHASER’S/OWNER’S WARRANTY RESPONSIBILITIES

YOUR WARRANTY RIGHTS AND OBLIGATIONS

MANUFACTURER’S EMISSION CONTROL SYSTEM WARRANTY COVERAGE

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

EMISSION CONTROL SYSTEM WARRANTY

EMISSION RELATED PARTS INCLUDE THE FOLLOWING

THIS WARRANTY SHALL NOT APPLY TO THE FOLLOWING

GENERAC POWER SYSTEMS TWO YEAR LIMITED WARRANTY FOR GUARDIAN

WARRANTY SCHEDULE

GENERAC POWER SYSTEMS, INC P.O. BOX 297 WHITEWATER, WI

![]()

![]()

![]()

![]()

![]()

![]() 7

7 ![]()

![]()

![]()