GP8155-R PUMP REPAIR INSTRUCTIONS

15) Replace seal retainer (33), seal (32) and clip ring (33B). Seal (32) must always be installed so the seal lip on the inside diameter faces the oil. Possible axial float of the seal retainer (33) to be compensated with shims (33C).

16)Mount cooling plate (K1) and gear cover (K3) with their respective seals (K2). When assembling the cooling circuit line, make sure that the oil cooler connection (K7) is always joined to the upper connection (K3) of the gear cover.

Heat ball bearings (74 and 75) first before pressing them on to the pinion. Press the cogwheel slightly on to the crankshaft so that the pinion (69) together with the ebaring (74) can be inserted.

Move the pinion (69) against the cogwheel and make them mate perfectly when mounting. Then carefully tap the cogwheel and the pinion simultaneously on to the crankshaft and into the bearing seat. Fit fitting disc (69) and secure screw (72) with Loctite. Fit the seal (76) on to the cylindrical pins (68).

Push the gear cover (66) carefully onto the bearing (75). Make sure that the radial shaft seal (73) does not get damaged during fitting onto the pinion.

![]() Before putting into operation again, turn the reduction gear shaft by hand at least four full turns to make sure the gear is correctly aligned.

Before putting into operation again, turn the reduction gear shaft by hand at least four full turns to make sure the gear is correctly aligned.

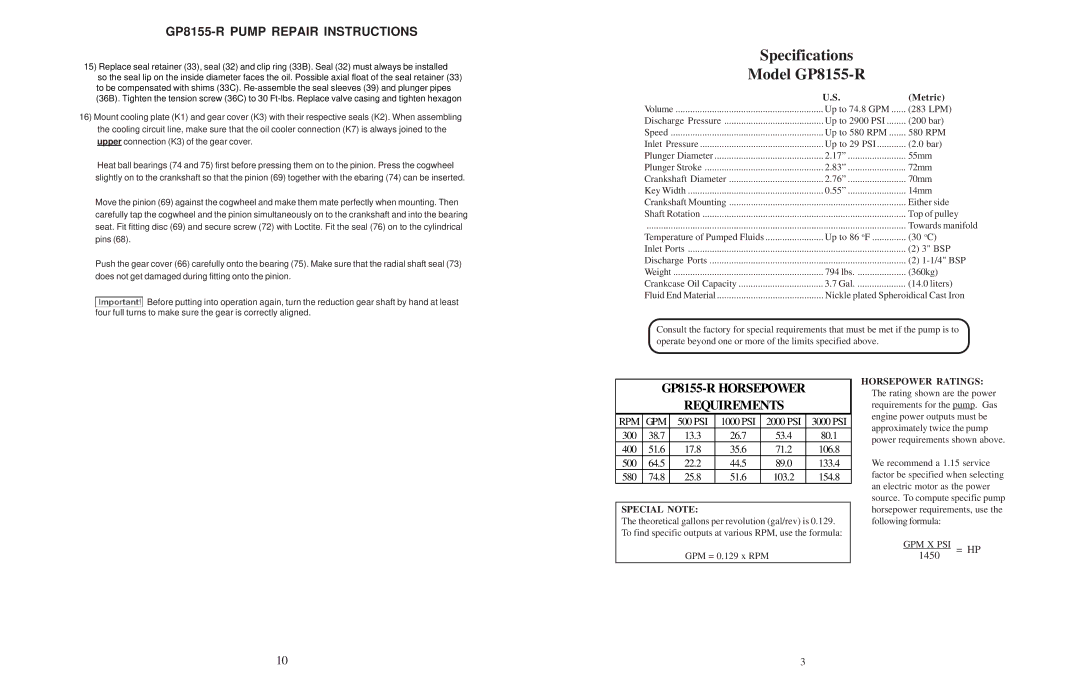

Specifications

Model GP8155-R

| U.S. | (Metric) |

Volume | Up to 74.8 GPM | (283 LPM) |

Discharge Pressure | Up to 2900 PSI | (200 bar) |

Speed | Up to 580 RPM | 580 RPM |

Inlet Pressure | Up to 29 PSI | (2.0 bar) |

Plunger Diameter | 2.17” | 55mm |

Plunger Stroke | 2.83” | 72mm |

Crankshaft Diameter | 2.76” | 70mm |

Key Width | 0.55” | 14mm |

Crankshaft Mounting | Either side | |

Shaft Rotation | Top of pulley | |

........................................................................................................... | Towards manifold | |

Temperature of Pumped Fluids | Up to 86 oF | (30 oC) |

Inlet Ports | (2) 3" BSP | |

Discharge Ports | (2) | |

Weight | 794 lbs | (360kg) |

Crankcase Oil Capacity | 3.7 Gal | (14.0 liters) |

Fluid End Material | Nickle plated Spheroidical Cast Iron | |

Consult the factory for special requirements that must be met if the pump is to operate beyond one or more of the limits specified above.

GP8155-R HORSEPOWER

REQUIREMENTS

RPM | GPM | 500 PSI | 1000 PSI | 2000 PSI | 3000 PSI |

300 | 38.7 | 13.3 | 26.7 | 53.4 | 80.1 |

400 | 51.6 | 17.8 | 35.6 | 71.2 | 106.8 |

500 | 64.5 | 22.2 | 44.5 | 89.0 | 133.4 |

580 | 74.8 | 25.8 | 51.6 | 103.2 | 154.8 |

SPECIAL NOTE:

The theoretical gallons per revolution (gal/rev) is 0.129. To find specific outputs at various RPM, use the formula:

GPM = 0.129 x RPM

HORSEPOWER RATINGS: The rating shown are the power requirements for the pump. Gas engine power outputs must be approximately twice the pump power requirements shown above.

We recommend a 1.15 service factor be specified when selecting an electric motor as the power source. To compute specific pump horsepower requirements, use the following formula:

GPM X PSI = HP 1450

10 | 3 |