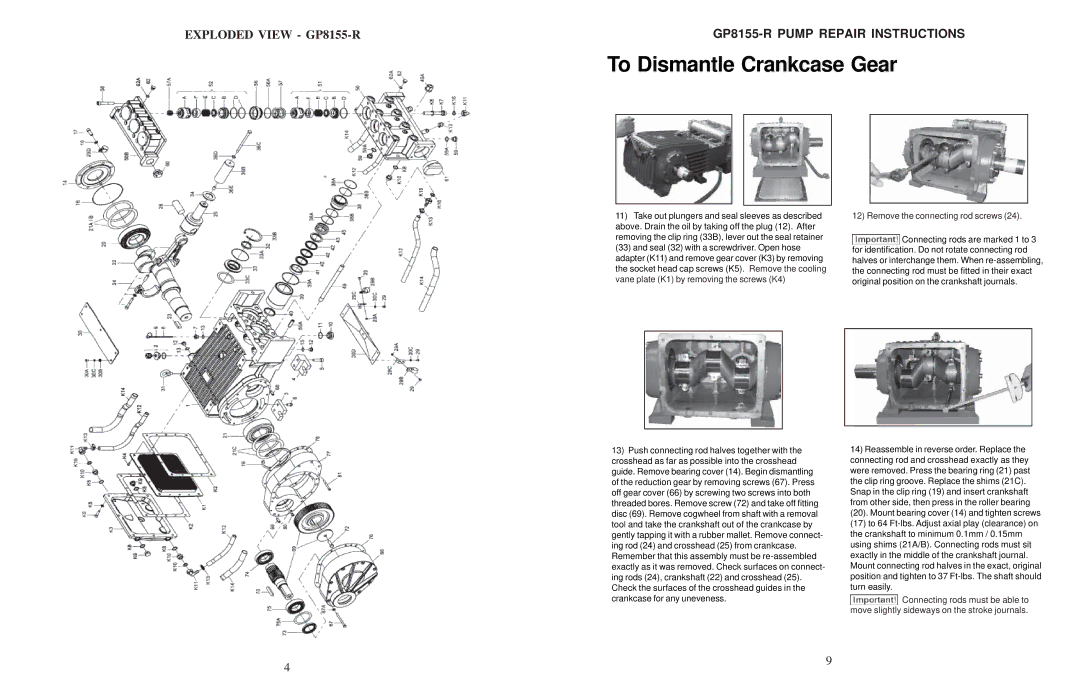

EXPLODED VIEW - |

|

To Dismantle Crankcase Gear

11)Take out plungers and seal sleeves as described above. Drain the oil by taking off the plug (12). After removing the clip ring (33B), lever out the seal retainer (33) and seal (32) with a screwdriver. Open hose adapter (K11) and remove gear cover (K3) by removing the socket head cap screws (K5). Remove the cooling vane plate (K1) by removing the screws (K4)

13)Push connecting rod halves together with the crosshead as far as possible into the crosshead guide. Remove bearing cover (14). Begin dismantling of the reduction gear by removing screws (67). Press off gear cover (66) by screwing two screws into both threaded bores. Remove screw (72) and take off fitting disc (69). Remove cogwheel from shaft with a removal tool and take the crankshaft out of the crankcase by gently tapping it with a rubber mallet. Remove connect- ing rod (24) and crosshead (25) from crankcase. Remember that this assembly must be

12) Remove the connecting rod screws (24).

![]() Connecting rods are marked 1 to 3 for identification. Do not rotate connecting rod halves or interchange them. When

Connecting rods are marked 1 to 3 for identification. Do not rotate connecting rod halves or interchange them. When

14)Reassemble in reverse order. Replace the connecting rod and crosshead exactly as they were removed. Press the bearing ring (21) past the clip ring groove. Replace the shims (21C). Snap in the clip ring (19) and insert crankshaft from other side, then press in the roller bearing (20). Mount bearing cover (14) and tighten screws (17) to 64

![]() Connecting rods must be able to move slightly sideways on the stroke journals.

Connecting rods must be able to move slightly sideways on the stroke journals.

4 | 9 |

|