Operation overview

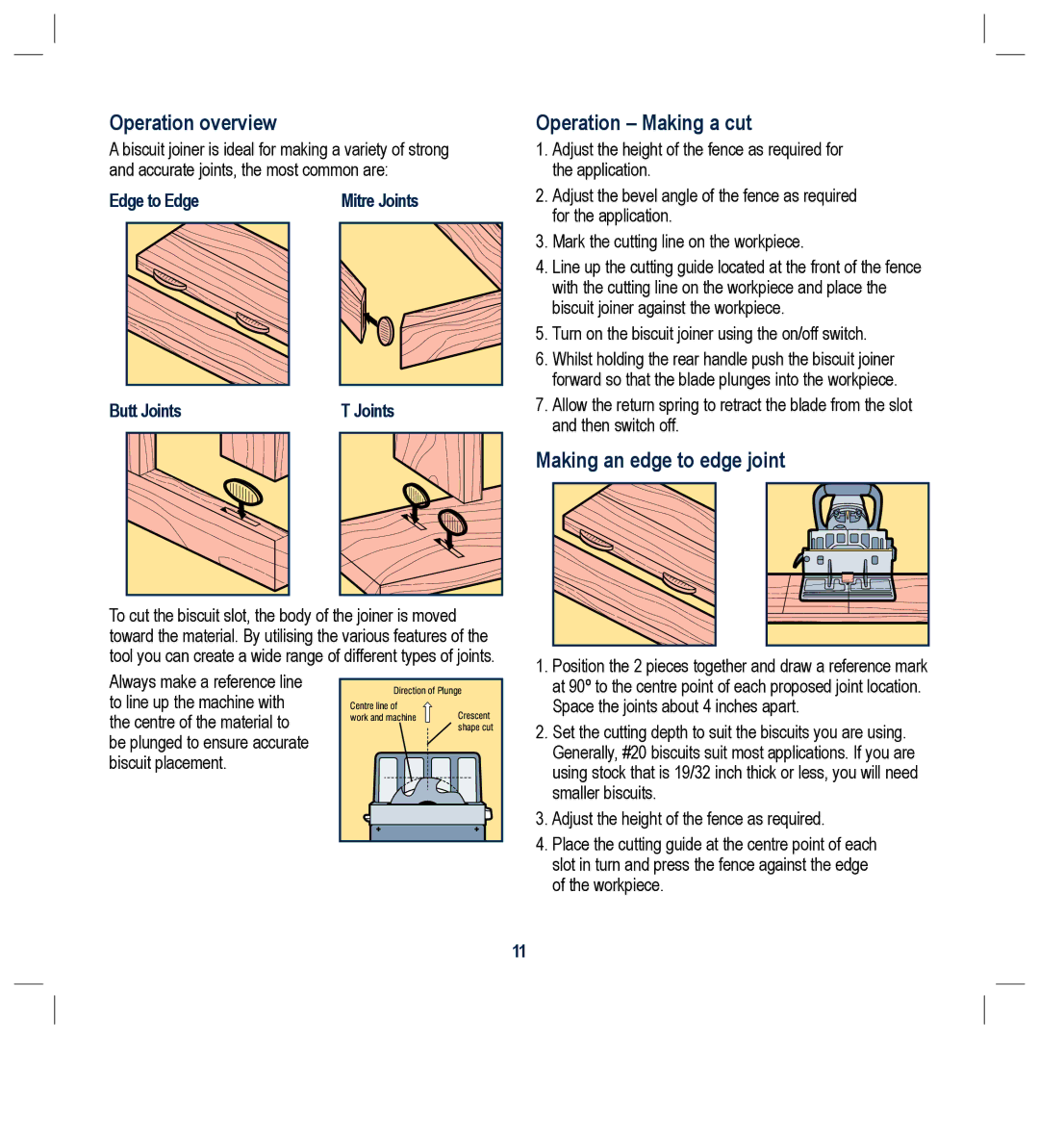

A biscuit joiner is ideal for making a variety of strong and accurate joints, the most common are:

Edge to Edge | Mitre Joints |

Butt Joints | T Joints |

Operation – Making a cut

1.Adjust the height of the fence as required for the application.

2.Adjust the bevel angle of the fence as required for the application.

3.Mark the cutting line on the workpiece.

4.Line up the cutting guide located at the front of the fence with the cutting line on the workpiece and place the biscuit joiner against the workpiece.

5.Turn on the biscuit joiner using the on/off switch.

6.Whilst holding the rear handle push the biscuit joiner forward so that the blade plunges into the workpiece.

7.Allow the return spring to retract the blade from the slot and then switch off.

Making an edge to edge joint

To cut the biscuit slot, the body of the joiner is moved toward the material. By utilising the various features of the tool you can create a wide range of different types of joints.

Centreline Mark(s)

1. Position the 2 pieces together and draw a reference mark |

Always make a reference line to line up the machine with the centre of the material to be plunged to ensure accurate biscuit placement.

Direction of Plunge | |

Centre line of | Crescent |

work and machine | |

| shape cut |

at 90º to the centre point of each proposed joint location. |

Space the joints about 4 inches apart. |

2. Set the cutting depth to suit the biscuits you are using. |

Generally, #20 biscuits suit most applications. If you are |

using stock that is 19/32 inch thick or less, you will need |

smaller biscuits. |

3. Adjust the height of the fence as required. |

4. Place the cutting guide at the centre point of each |

slot in turn and press the fence against the edge |

of the workpiece. |

11