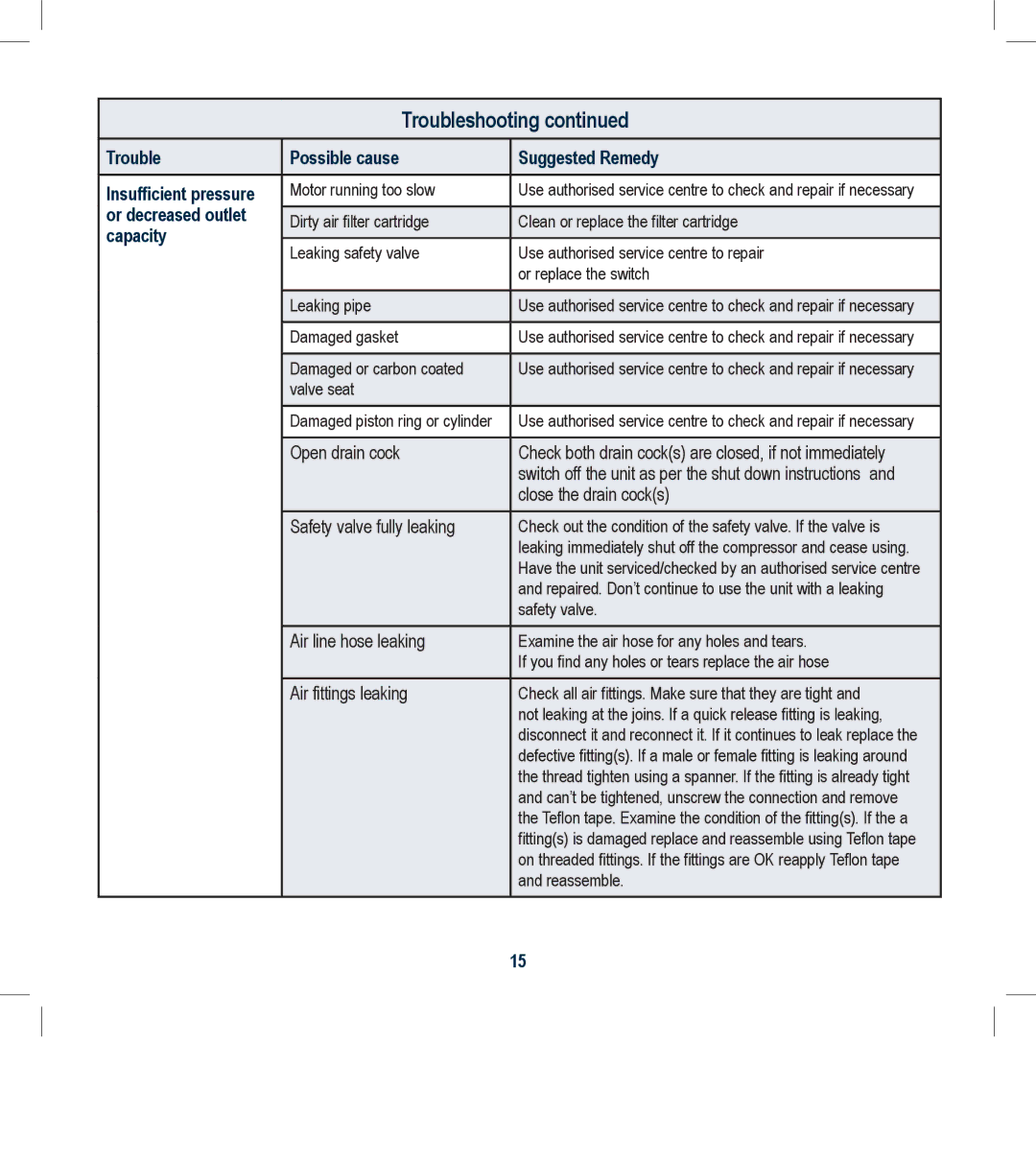

Troubleshooting continued

Trouble | Possible cause | Suggested Remedy | |

|

|

| |

Insufficient pressure | Motor running too slow | Use authorised service centre to check and repair if necessary | |

or decreased outlet | Dirty air filter cartridge | Clean or replace the filter cartridge | |

capacity | |||

|

| ||

Leaking safety valve | Use authorised service centre to repair | ||

| |||

|

| or replace the switch | |

|

|

| |

| Leaking pipe | Use authorised service centre to check and repair if necessary | |

|

|

| |

| Damaged gasket | Use authorised service centre to check and repair if necessary | |

|

|

| |

| Damaged or carbon coated | Use authorised service centre to check and repair if necessary | |

| valve seat |

| |

|

|

| |

| Damaged piston ring or cylinder | Use authorised service centre to check and repair if necessary | |

|

|

| |

| Open drain cock | Check both drain cock(s) are closed, if not immediately | |

|

| switch off the unit as per the shut down instructions and | |

|

| close the drain cock(s) | |

|

|

| |

| Safety valve fully leaking | Check out the condition of the safety valve. If the valve is | |

|

| leaking immediately shut off the compressor and cease using. | |

|

| Have the unit serviced/checked by an authorised service centre | |

|

| and repaired. Don’t continue to use the unit with a leaking | |

|

| safety valve. | |

|

|

| |

| Air line hose leaking | Examine the air hose for any holes and tears. | |

|

| If you find any holes or tears replace the air hose | |

|

|

| |

| Air fittings leaking | Check all air fittings. Make sure that they are tight and | |

|

| not leaking at the joins. If a quick release fitting is leaking, | |

|

| disconnect it and reconnect it. If it continues to leak replace the | |

|

| defective fitting(s). If a male or female fitting is leaking around | |

|

| the thread tighten using a spanner. If the fitting is already tight | |

|

| and can’t be tightened, unscrew the connection and remove | |

|

| the Teflon tape. Examine the condition of the fitting(s). If the a | |

|

| fitting(s) is damaged replace and reassemble using Teflon tape | |

|

| on threaded fittings. If the fittings are OK reapply Teflon tape | |

|

| and reassemble. | |

|

|

|

15