3 Commissioning

3.1 Filling the secondary circuit

IMPORTANT: Risk of damage! Do not manually open the temperature/pressure relief valve or the expansion vessel for venting purposes. Any foreign matter in the pipework may cause damage to the valve seats.

Make sure the cylinder drain valve is closed.

Open all cold and hot water taps and the corresponding outlets.

Open the mains water supply to the Flurocyl and fill it with water until it flows freely out of the outlets. Make sure all air bubbles have been removed.

Close the outlets and check the system for leaks. Check in particular the immersion heater connection for leaks.

The system must now be flushed thoroughly.

Open the hot water taps at the opposite ends of the systems and let the water flow out for at least 5 minutes.

Close the hot water taps.

3.2 Setting the thermostatic mixing valve

The hot water from the solar cylinder can be set to a desired maximum temperature between 30 °C and 70 °C by mixing hot and cold water.

Set the hot water thermostatic mixing valve with the adjusting knob to maintain the householders desired temperature at the hot water taps.

IMPORTANT: Risk of being scalded by hot water! Set the thermostat mixer to 60 °C or below and check the temperature at a hot water tap to ensure effective protection against scalding.

3.3 Reheat circuit (boiler circuit)

NOTE: Do not use the pressure relief valve of the boiler (if applicable) for bleeding.

Flush the entire primary central heating system with cold and hot water. Fill and bleed the central heating system according to the installation manual of the boiler.

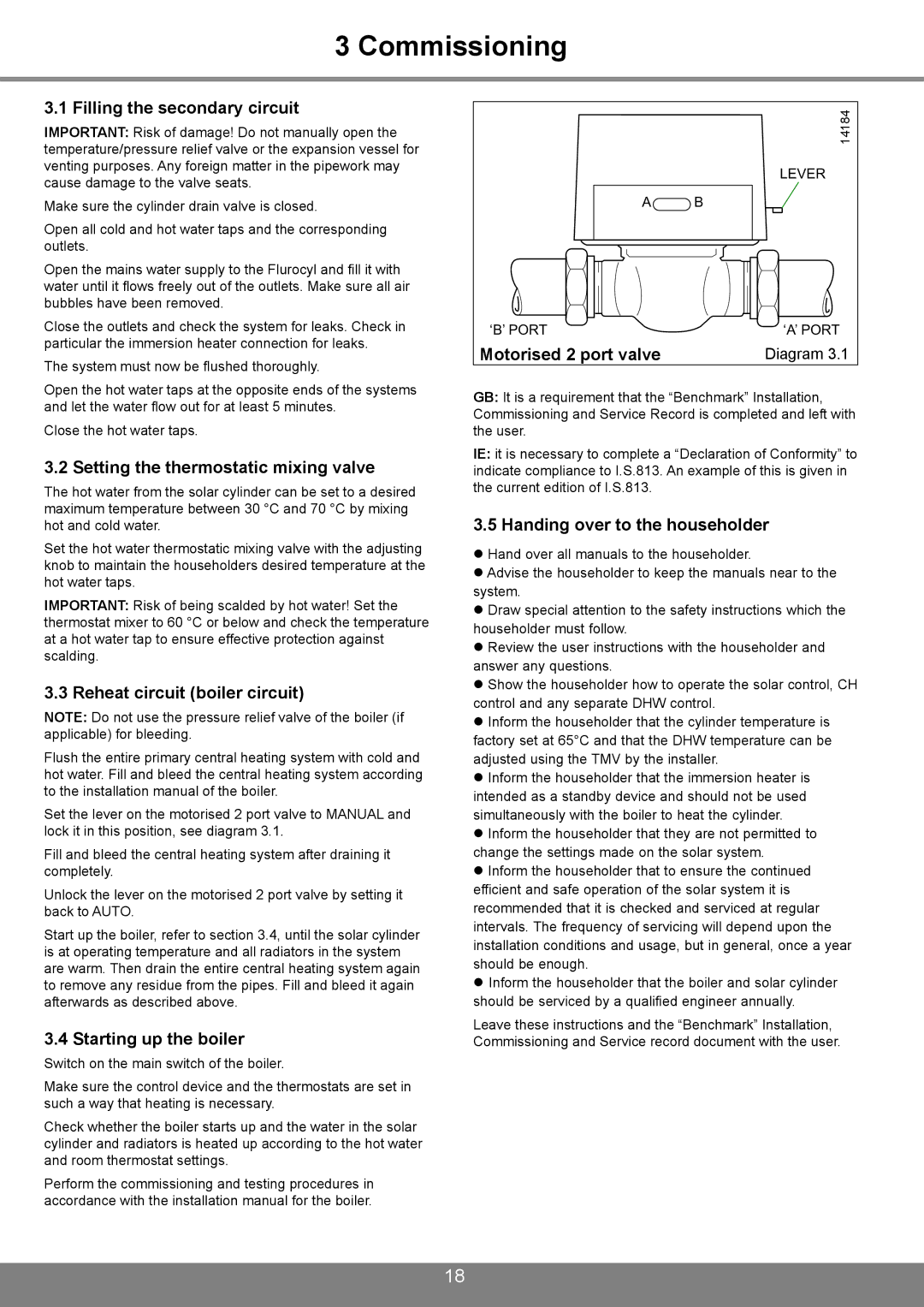

Set the lever on the motorised 2 port valve to MANUAL and lock it in this position, see diagram 3.1.

Fill and bleed the central heating system after draining it completely.

Unlock the lever on the motorised 2 port valve by setting it back to AUTO.

Start up the boiler, refer to section 3.4, until the solar cylinder is at operating temperature and all radiators in the system are warm. Then drain the entire central heating system again to remove any residue from the pipes. Fill and bleed it again afterwards as described above.

3.4 Starting up the boiler

Switch on the main switch of the boiler.

Make sure the control device and the thermostats are set in such a way that heating is necessary.

Check whether the boiler starts up and the water in the solar cylinder and radiators is heated up according to the hot water and room thermostat settings.

Perform the commissioning and testing procedures in accordance with the installation manual for the boiler.

| 14184 |

| LEVER |

A | B |

‘B’ PORT | ‘A’ PORT |

Motorised 2 port valve | Diagram 3.1 |

GB: It is a requirement that the “Benchmark” Installation, Commissioning and Service Record is completed and left with the user.

IE: it is necessary to complete a “Declaration of Conformity” to indicate compliance to I.S.813. An example of this is given in the current edition of I.S.813.

3.5 Handing over to the householder

•Hand over all manuals to the householder.

•Advise the householder to keep the manuals near to the system.

•Draw special attention to the safety instructions which the householder must follow.

•Review the user instructions with the householder and answer any questions.

•Show the householder how to operate the solar control, CH control and any separate DHW control.

•Inform the householder that the cylinder temperature is factory set at 65°C and that the DHW temperature can be adjusted using the TMV by the installer.

•Inform the householder that the immersion heater is intended as a standby device and should not be used simultaneously with the boiler to heat the cylinder.

•Inform the householder that they are not permitted to change the settings made on the solar system.

•Inform the householder that to ensure the continued efficient and safe operation of the solar system it is recommended that it is checked and serviced at regular intervals. The frequency of servicing will depend upon the installation conditions and usage, but in general, once a year should be enough.

•Inform the householder that the boiler and solar cylinder should be serviced by a qualified engineer annually.

Leave these instructions and the “Benchmark” Installation, Commissioning and Service record document with the user.

18