Product Specifications

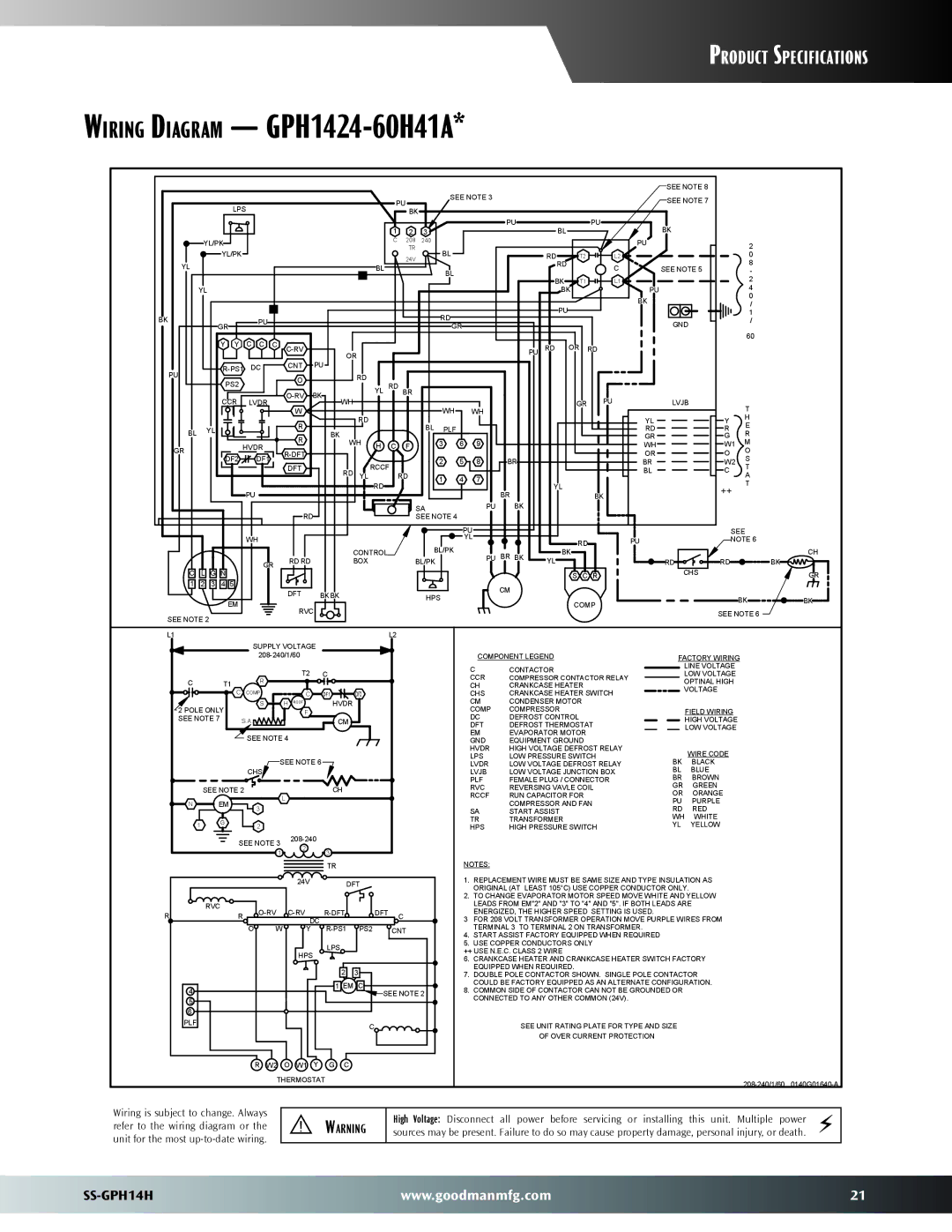

Wiring Diagram — GPH1424-60H41A*

BK

LPS

![]() YL/PK

YL/PK![]()

![]() YL/PK

YL/PK

YL

YL

GR

BL

PU

PU |

| SEE NOTE 3 |

BK |

| |

|

| |

1 |

| PU |

2 | 3 | |

C | 208 | 240 |

| TR | BL |

| 24V | |

|

| |

BL |

| BL |

BL |

| |

|

| RD |

|

| GR |

BL

RD

![]() RD

RD

BK

BK

PU

PU

T2 ![]()

![]() L2

L2 ![]()

C

T1 ![]()

![]() L1

L1 ![]()

SEE NOTE 8

SEE NOTE 7

BK

PU

SEE NOTE 5

PU

BK

GND

2

0

8

-

2

4

0

/

1

/

PU

BL YL

GR

Y Y | C C | C |

|

|

|

|

|

|

| |

|

|

|

| OR |

|

|

|

|

| |

|

|

|

| PU |

|

|

|

|

| |

DC |

| CNT | RD |

|

|

|

|

| ||

PS2 |

|

| O |

| YL RD BR |

|

|

| ||

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| |||

|

|

| BK |

|

|

|

| |||

CCR | LVDR |

| WH |

|

|

|

|

| ||

| W |

|

|

| WH | WH | ||||

|

|

|

| RD |

|

| ||||

|

|

| R |

|

|

| BL |

|

| |

|

|

|

| BK |

|

| PLF |

| ||

|

|

| R |

|

|

|

|

|

| |

HVDR |

|

| WH | H C | F | 3 | 6 | 9 | ||

|

|

| ||||||||

|

|

|

|

|

| |||||

DF2 | DF1 |

|

|

|

|

| 2 | 5 | 8 | |

| DFT |

|

| RCCF |

| |||||

|

|

|

|

|

| |||||

|

|

|

| RD YL | RD |

|

|

| ||

|

|

|

|

|

| 1 | 4 | 7 | ||

|

|

|

|

|

| RD |

| |||

| PU |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

| RD |

|

|

| SA |

| PU | |

|

|

|

|

|

| SEE NOTE 4 |

| |||

BR

BR

BK

PU

RD OR RD

GR | PU |

|

YL

BK

LVJB

YL

RD

GR

WH

OR

BR

BL

60

T

YH

R E

GR

W1 M O O W2 S

C T

A

++T

|

|

|

| WH |

|

|

|

|

|

|

|

| CONTROL |

|

|

|

| GR | RD RD | BOX |

C | L | G N |

|

| ||

|

|

| ||||

1 | 2 | 3 | 4 | 5 |

|

|

|

|

|

| EM | DFT | BKBK |

|

|

|

| RVC |

| |

SEE NOTE 2 |

|

|

|

| ||

|

|

|

|

| ||

L1 |

|

|

|

|

| L2 |

|

|

|

| SUPPLY VOLTAGE |

| |

| PU |

|

|

|

|

| SEE |

|

| YL |

|

|

| RD | PU | NOTE 6 |

|

|

|

|

|

|

| |||

BL/PK |

|

|

|

|

|

| ||

|

|

| BK |

|

| CH | ||

PU | BR | BK |

|

|

| |||

|

|

|

| |||||

BL/PK | YL |

| RD | RD | BK | |||

|

|

|

| |||||

|

|

|

| S | C R |

| CHS | GR |

|

|

|

|

|

|

| ||

HPS |

| CM |

|

|

|

|

|

|

|

|

| COMP |

| BK | BK | ||

|

|

|

|

| SEE NOTE 6 |

| ||

|

|

|

|

|

|

|

| |

|

|

|

| |||

C |

| R |

| T2 | C |

|

T1 |

|

|

|

| ||

C COMP |

|

|

|

| ||

|

|

| C | DF1 | DF2 | |

2 POLE ONLY | S | H | RCCF |

| HVDR | |

|

| F |

|

| ||

SEE NOTE 7 |

|

|

|

| ||

S.A. |

|

|

| CM | ||

|

|

|

|

| ||

|

| SEE NOTE 4 |

|

|

| |

|

|

| SEE NOTE 6 |

|

| |

|

| CHS |

|

|

|

|

| SEE NOTE 2 | L |

|

| CH | |

N | EM |

|

|

|

| |

3 |

|

|

|

| ||

|

|

|

|

|

| |

1 | G | 2 |

|

|

|

|

|

|

|

|

| ||

|

| SEE NOTE 3 |

|

| ||

|

| 2 |

|

| ||

|

|

| 1 | 3 |

| |

|

|

|

|

| ||

TR

COMPONENT LEGEND

C | CONTACTOR |

CCR | COMPRESSOR CONTACTOR RELAY |

CH | CRANKCASE HEATER |

CHS | CRANKCASE HEATER SWITCH |

CM | CONDENSER MOTOR |

COMP | COMPRESSOR |

DC | DEFROST CONTROL |

DFT | DEFROST THERMOSTAT |

EM | EVAPORATOR MOTOR |

GND | EQUIPMENT GROUND |

HVDR | HIGH VOLTAGE DEFROST RELAY |

LPS | LOW PRESSURE SWITCH |

LVDR | LOW VOLTAGE DEFROST RELAY |

LVJB | LOW VOLTAGE JUNCTION BOX |

PLF | FEMALE PLUG / CONNECTOR |

RVC | REVERSING VAVLE COIL |

RCCF | RUN CAPACITOR FOR |

| COMPRESSOR AND FAN |

SA | START ASSIST |

TR | TRANSFORMER |

HPS | HIGH PRESSURE SWITCH |

NOTES: |

|

FACTORY WIRING

LINE VOLTAGE

LOW VOLTAGE

OPTINAL HIGH

VOLTAGE

FIELD WIRING

HIGH VOLTAGE

LOW VOLTAGE

| WIRE CODE |

BK | BLACK |

BL | BLUE |

BR | BROWN |

GR | GREEN |

OR | ORANGE |

PU | PURPLE |

RD | RED |

WH | WHITE |

YL | YELLOW |

R

|

| 24V | DFT |

|

| |

|

|

|

|

| ||

RVC |

| DFT |

| |||

R |

| C | ||||

| DC |

|

|

| ||

O | W | PS2 |

|

| ||

Y |

| CNT | ||||

|

|

|

|

|

| |

|

| HPS | LPS |

|

|

|

|

|

|

|

|

| |

|

|

| 2 | 3 |

|

|

4 |

|

| 1 EM C | SEE NOTE 2 | ||

|

|

|

| |||

5 |

|

|

|

| ||

|

|

|

|

|

| |

6 |

|

|

|

|

|

|

PLF |

|

|

| C |

|

|

|

|

|

|

|

| |

1.REPLACEMENT WIRE MUST BE SAME SIZE AND TYPE INSULATION AS ORIGINAL (AT LEAST 105°C) USE COPPER CONDUCTOR ONLY.

2.TO CHANGE EVAPORATOR MOTOR SPEED MOVE WHITE AND YELLOW

LEADS FROM EM"2" AND "3" TO "4" AND "5". IF BOTH LEADS ARE ENERGIZED, THE HIGHER SPEED SETTING IS USED.

3FOR 208 VOLT TRANSFORMER OPERATION MOVE PURPLE WIRES FROM TERMINAL 3 TO TERMINAL 2 ON TRANSFORMER.

4.START ASSIST FACTORY EQUIPPED WHEN REQUIRED

5.USE COPPER CONDUCTORS ONLY

++ USE N.E.C. CLASS 2 WIRE

6.CRANKCASE HEATER AND CRANKCASE HEATER SWITCH FACTORY EQUIPPED WHEN REQUIRED.

7.DOUBLE POLE CONTACTOR SHOWN. SINGLE POLE CONTACTOR COULD BE FACTORY EQUIPPED AS AN ALTERNATE CONFIGURATION.

8.COMMON SIDE OF CONTACTOR CAN NOT BE GROUNDED OR CONNECTED TO ANY OTHER COMMON (24V).

SEE UNIT RATING PLATE FOR TYPE AND SIZE

OF OVER CURRENT PROTECTION

R | W2 O W1 Y | G | C |

| THERMOSTAT |

| |

|

|

|

Wiring is subject to change. Always refer to the wiring diagram or the unit for the most

⚠Warning

High Voltage: Disconnect all power before servicing or installing this unit. Multiple power ⚡ sources may be present. Failure to do so may cause property damage, personal injury, or death.

www.goodmanmfg.com | 21 |