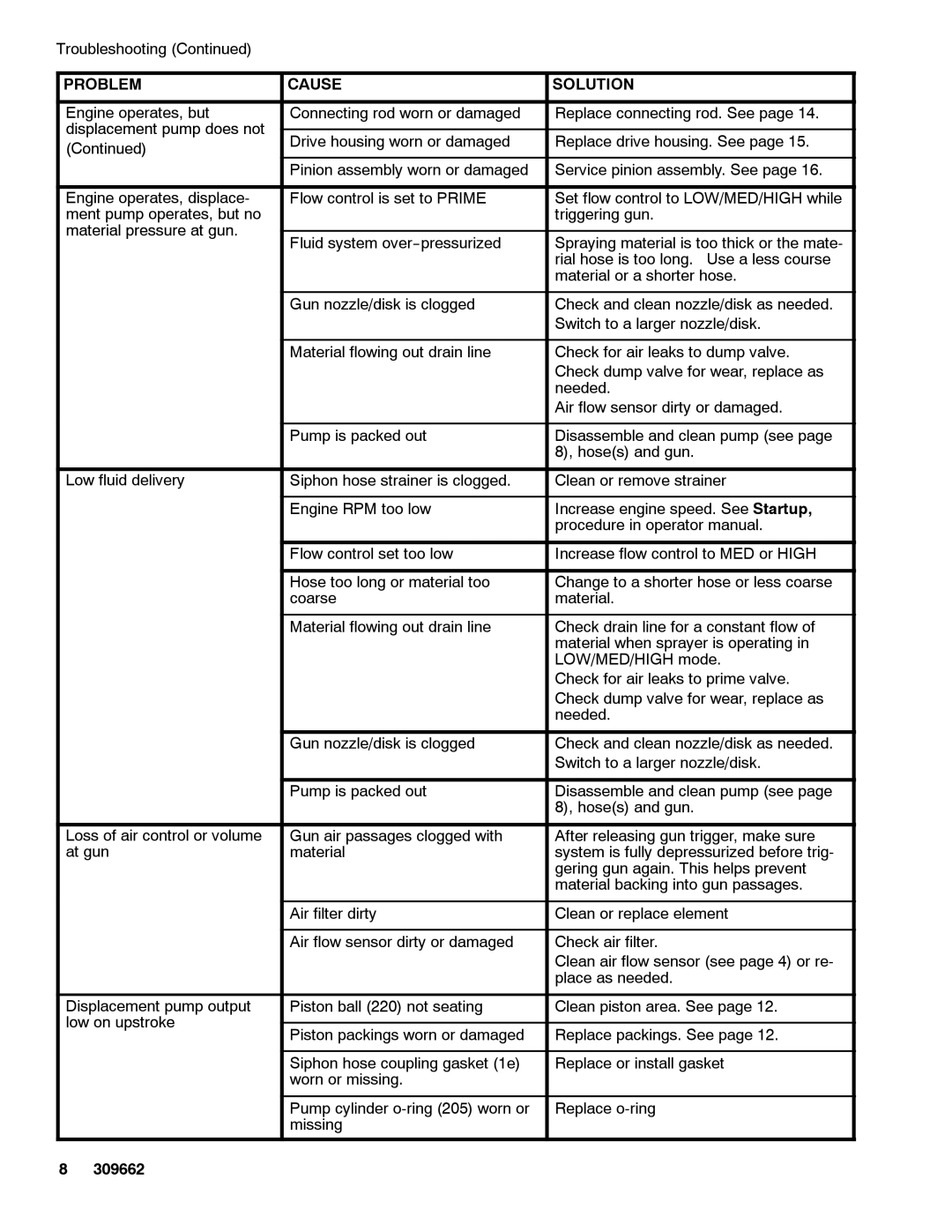

Troubleshooting (Continued)

PROBLEM | CAUSE | SOLUTION | |

|

|

| |

Engine operates, but | Connecting rod worn or damaged | Replace connecting rod. See page 14. | |

displacement pump does not |

|

| |

Drive housing worn or damaged | Replace drive housing. See page 15. | ||

(Continued) | |||

|

| ||

| Pinion assembly worn or damaged | Service pinion assembly. See page 16. | |

|

|

| |

Engine operates, displace- | Flow control is set to PRIME | Set flow control to LOW/MED/HIGH while | |

ment pump operates, but no |

| triggering gun. | |

material pressure at gun. |

|

| |

Fluid system | Spraying material is too thick or the mate- | ||

| |||

|

| rial hose is too long. Use a less course | |

|

| material or a shorter hose. | |

|

|

| |

| Gun nozzle/disk is clogged | Check and clean nozzle/disk as needed. | |

|

| Switch to a larger nozzle/disk. | |

|

|

| |

| Material flowing out drain line | Check for air leaks to dump valve. | |

|

| Check dump valve for wear, replace as | |

|

| needed. | |

|

| Air flow sensor dirty or damaged. | |

|

|

| |

| Pump is packed out | Disassemble and clean pump (see page | |

|

| 8), hose(s) and gun. | |

|

|

| |

Low fluid delivery | Siphon hose strainer is clogged. | Clean or remove strainer | |

|

|

| |

| Engine RPM too low | Increase engine speed. See Startup, | |

|

| procedure in operator manual. | |

|

|

| |

| Flow control set too low | Increase flow control to MED or HIGH | |

|

|

| |

| Hose too long or material too | Change to a shorter hose or less coarse | |

| coarse | material. | |

|

|

| |

| Material flowing out drain line | Check drain line for a constant flow of | |

|

| material when sprayer is operating in | |

|

| LOW/MED/HIGH mode. | |

|

| Check for air leaks to prime valve. | |

|

| Check dump valve for wear, replace as | |

|

| needed. | |

|

|

| |

| Gun nozzle/disk is clogged | Check and clean nozzle/disk as needed. | |

|

| Switch to a larger nozzle/disk. | |

|

|

| |

| Pump is packed out | Disassemble and clean pump (see page | |

|

| 8), hose(s) and gun. | |

|

|

| |

Loss of air control or volume | Gun air passages clogged with | After releasing gun trigger, make sure | |

at gun | material | system is fully depressurized before trig- | |

|

| gering gun again. This helps prevent | |

|

| material backing into gun passages. | |

|

|

| |

| Air filter dirty | Clean or replace element | |

|

|

| |

| Air flow sensor dirty or damaged | Check air filter. | |

|

| Clean air flow sensor (see page 4) or re- | |

|

| place as needed. | |

|

|

| |

Displacement pump output | Piston ball (220) not seating | Clean piston area. See page 12. | |

low on upstroke |

|

| |

Piston packings worn or damaged | Replace packings. See page 12. | ||

| |||

|

|

| |

| Siphon hose coupling gasket (1e) | Replace or install gasket | |

| worn or missing. |

| |

|

|

| |

| Pump cylinder | Replace | |

| missing |

| |

|

|

|