Before Beginning Repair

Before Beginning Repair

Maintenance Procedures

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the Pressure Relief procedure.

Platen Maintenance

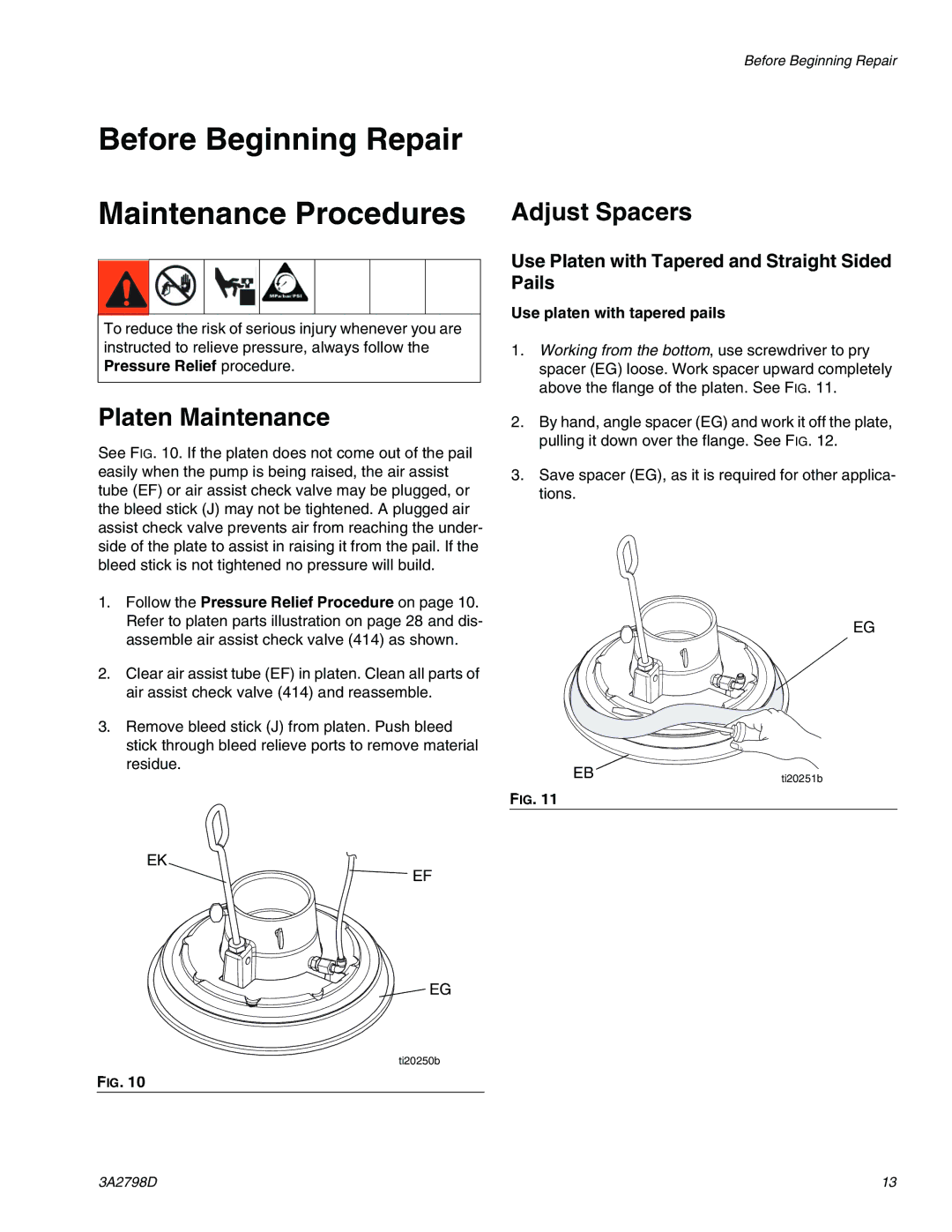

See FIG. 10. If the platen does not come out of the pail easily when the pump is being raised, the air assist tube (EF) or air assist check valve may be plugged, or the bleed stick (J) may not be tightened. A plugged air assist check valve prevents air from reaching the under- side of the plate to assist in raising it from the pail. If the bleed stick is not tightened no pressure will build.

1.Follow the Pressure Relief Procedure on page 10. Refer to platen parts illustration on page 28 and dis- assemble air assist check valve (414) as shown.

2.Clear air assist tube (EF) in platen. Clean all parts of air assist check valve (414) and reassemble.

3.Remove bleed stick (J) from platen. Push bleed stick through bleed relieve ports to remove material residue.

EK

![]() EF

EF

![]() EG

EG

ti20250b

FIG. 10

Adjust Spacers

Use Platen with Tapered and Straight Sided Pails

Use platen with tapered pails

1.Working from the bottom, use screwdriver to pry spacer (EG) loose. Work spacer upward completely above the flange of the platen. See FIG. 11.

2.By hand, angle spacer (EG) and work it off the plate, pulling it down over the flange. See FIG. 12.

3.Save spacer (EG), as it is required for other applica- tions.

EG

EB | ti20251b |

|

FIG. 11

3A2798D | 13 |