Repair

Assemble Piston Rod Seal and Bearing

See FIG. 18 on page 20.

1.Lubricate

a.Install

b.Install new

c.Slide spring (302m) and end cap (302b) on pis- ton rod (302a).

2.Install retaining ring (303).

3.Remount mounting plate (331) and attach nuts (333) and lockwashers (332). Torque to 40

Disassemble Ram Piston

1.Complete steps

NOTICE

Do not tilt the piston rod to one side when removing it from the base or when installing it. Such movement can damage the piston or inside surface of the base cylinder.

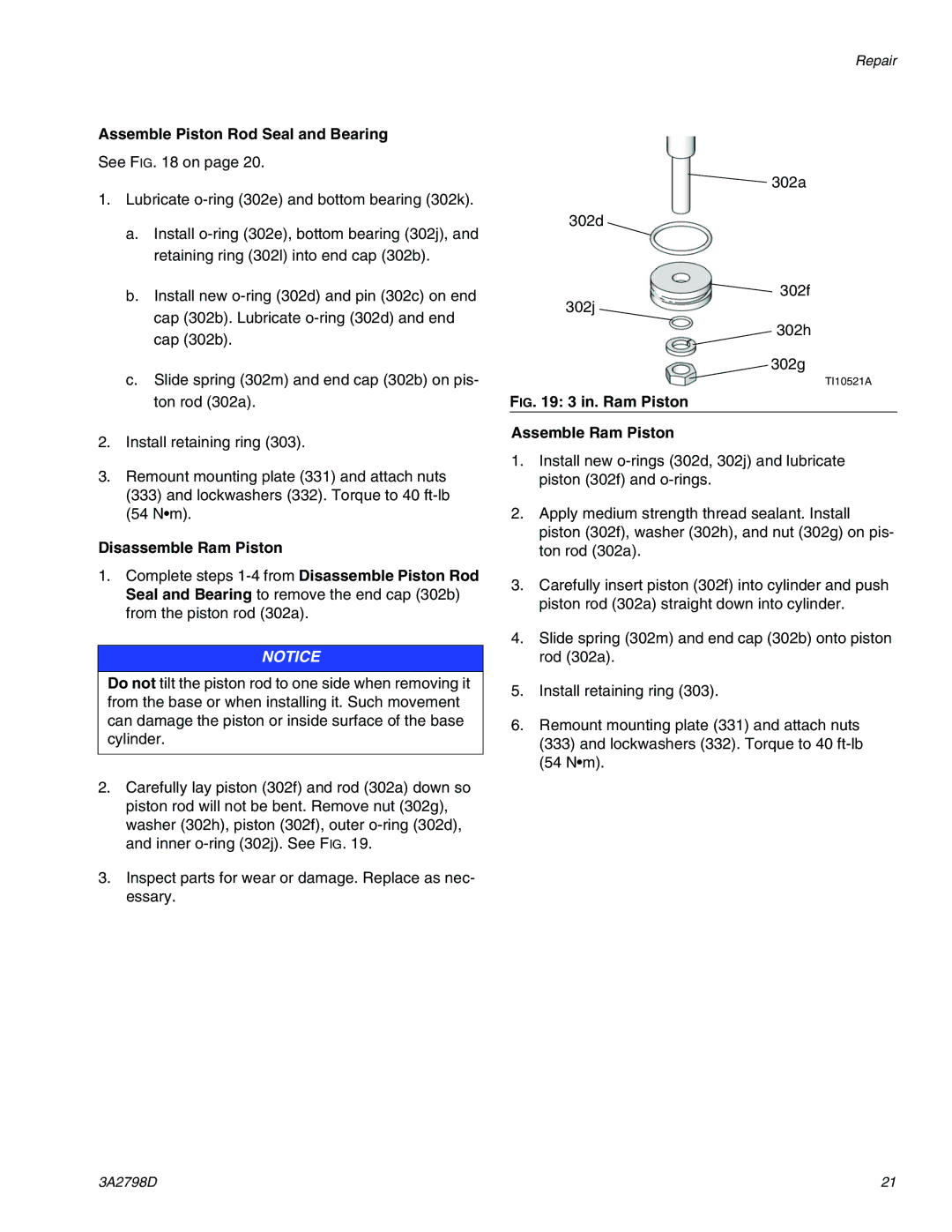

2.Carefully lay piston (302f) and rod (302a) down so piston rod will not be bent. Remove nut (302g), washer (302h), piston (302f), outer

3.Inspect parts for wear or damage. Replace as nec- essary.

![]() 302a

302a

302d

![]() 302f

302f

302j

302h

302g

TI10521A

FIG. 19: 3 in. Ram Piston

Assemble Ram Piston

1.Install new

2.Apply medium strength thread sealant. Install piston (302f), washer (302h), and nut (302g) on pis- ton rod (302a).

3.Carefully insert piston (302f) into cylinder and push piston rod (302a) straight down into cylinder.

4.Slide spring (302m) and end cap (302b) onto piston rod (302a).

5.Install retaining ring (303).

6.Remount mounting plate (331) and attach nuts

(333)and lockwashers (332). Torque to 40

3A2798D | 21 |