Troubleshooting

Troubleshooting

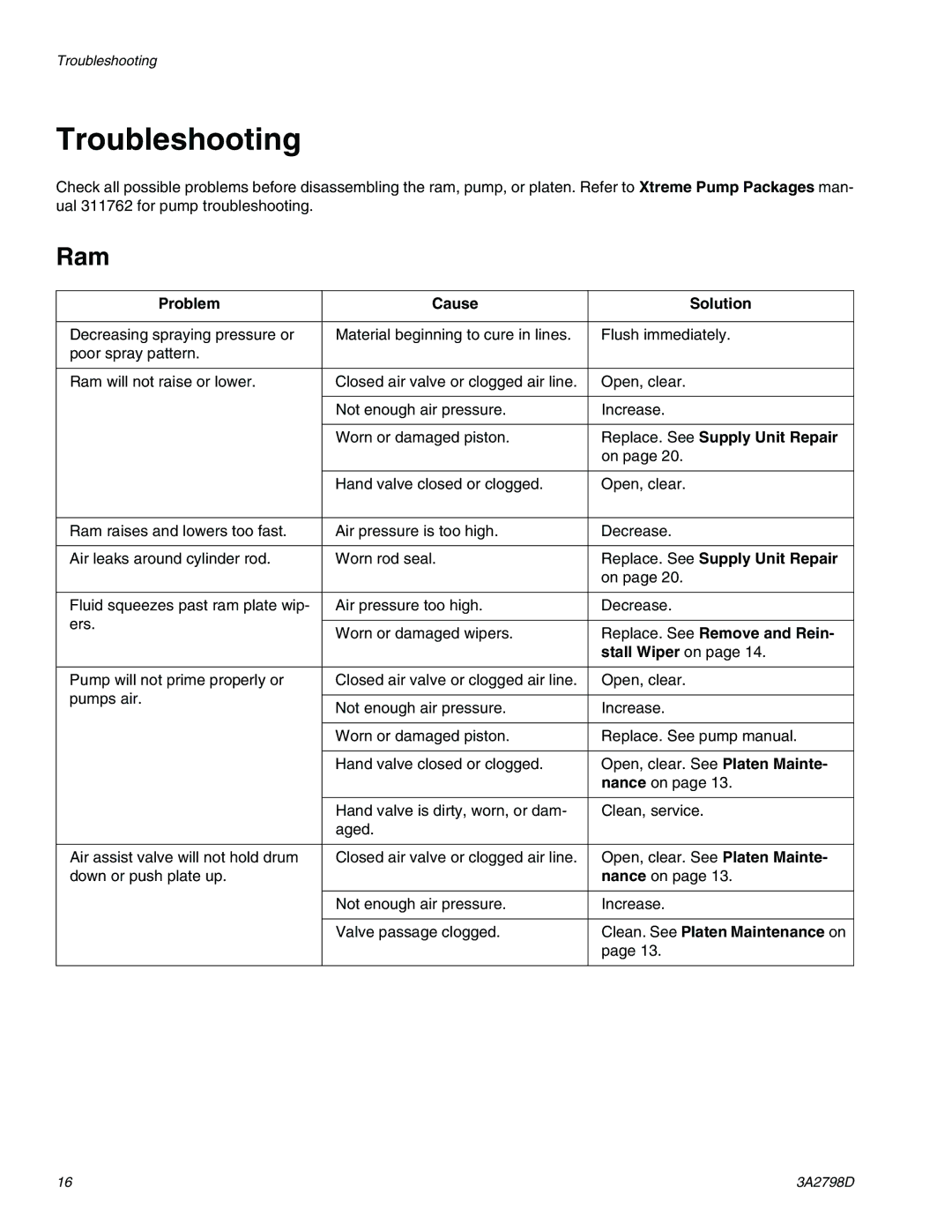

Check all possible problems before disassembling the ram, pump, or platen. Refer to Xtreme Pump Packages man- ual 311762 for pump troubleshooting.

Ram

Problem | Cause | Solution | |

|

|

| |

Decreasing spraying pressure or | Material beginning to cure in lines. | Flush immediately. | |

poor spray pattern. |

|

| |

|

|

| |

Ram will not raise or lower. | Closed air valve or clogged air line. | Open, clear. | |

|

|

| |

| Not enough air pressure. | Increase. | |

|

|

| |

| Worn or damaged piston. | Replace. See Supply Unit Repair | |

|

| on page 20. | |

|

|

| |

| Hand valve closed or clogged. | Open, clear. | |

|

|

| |

Ram raises and lowers too fast. | Air pressure is too high. | Decrease. | |

|

|

| |

Air leaks around cylinder rod. | Worn rod seal. | Replace. See Supply Unit Repair | |

|

| on page 20. | |

|

|

| |

Fluid squeezes past ram plate wip- | Air pressure too high. | Decrease. | |

ers. |

|

| |

Worn or damaged wipers. | Replace. See Remove and Rein- | ||

| |||

|

| stall Wiper on page 14. | |

|

|

| |

Pump will not prime properly or | Closed air valve or clogged air line. | Open, clear. | |

pumps air. |

|

| |

Not enough air pressure. | Increase. | ||

| |||

|

|

| |

| Worn or damaged piston. | Replace. See pump manual. | |

|

|

| |

| Hand valve closed or clogged. | Open, clear. See Platen Mainte- | |

|

| nance on page 13. | |

|

|

| |

| Hand valve is dirty, worn, or dam- | Clean, service. | |

| aged. |

| |

|

|

| |

Air assist valve will not hold drum | Closed air valve or clogged air line. | Open, clear. See Platen Mainte- | |

down or push plate up. |

| nance on page 13. | |

|

|

| |

| Not enough air pressure. | Increase. | |

|

|

| |

| Valve passage clogged. | Clean. See Platen Maintenance on | |

|

| page 13. | |

|

|

|

16 | 3A2798D |