Installation

Connect the Air Lines

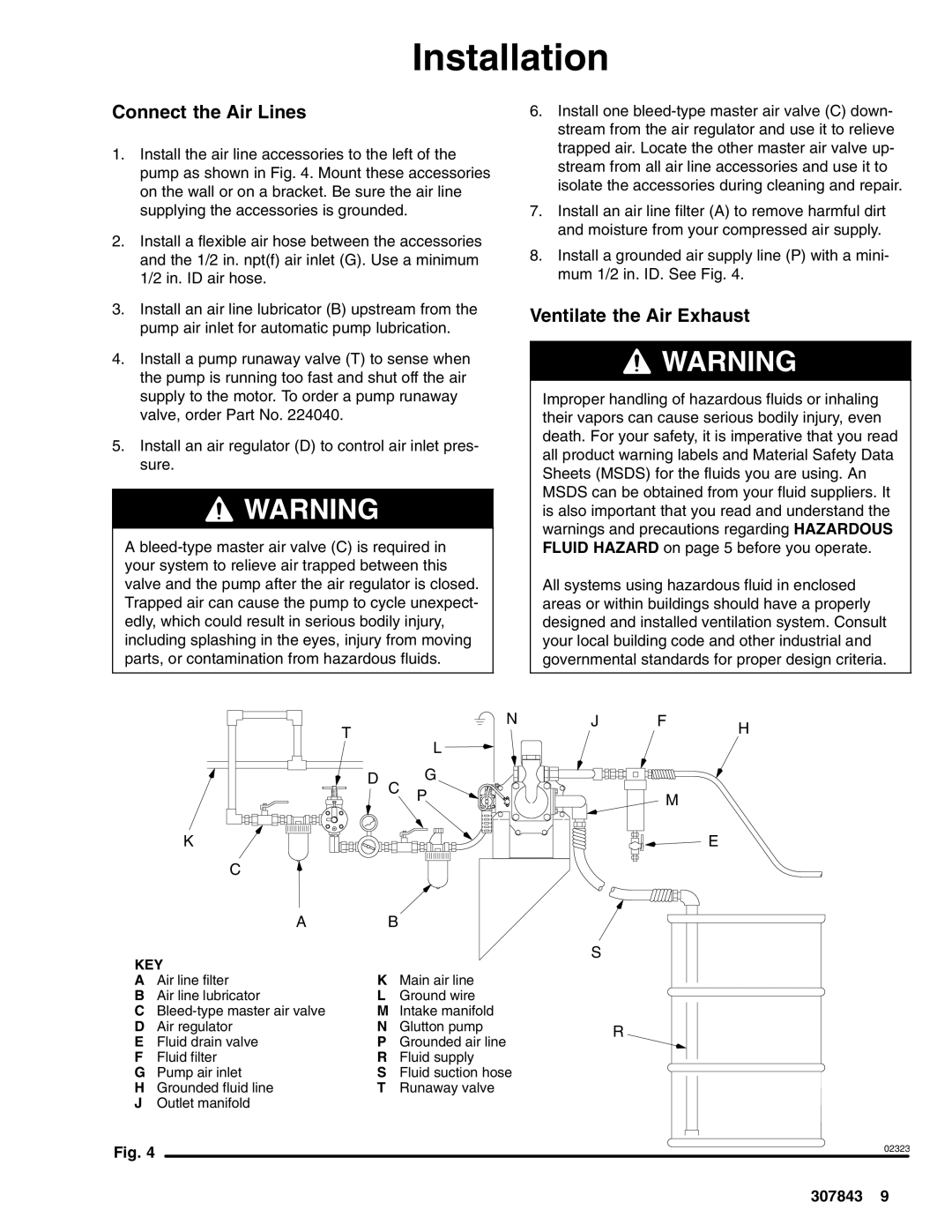

1.Install the air line accessories to the left of the pump as shown in Fig. 4. Mount these accessories on the wall or on a bracket. Be sure the air line supplying the accessories is grounded.

2.Install a flexible air hose between the accessories and the 1/2 in. npt(f) air inlet (G). Use a minimum 1/2 in. ID air hose.

3.Install an air line lubricator (B) upstream from the pump air inlet for automatic pump lubrication.

4.Install a pump runaway valve (T) to sense when the pump is running too fast and shut off the air supply to the motor. To order a pump runaway valve, order Part No. 224040.

5.Install an air regulator (D) to control air inlet pres- sure.

![]() WARNING

WARNING

A

6.Install one

7.Install an air line filter (A) to remove harmful dirt and moisture from your compressed air supply.

8.Install a grounded air supply line (P) with a mini- mum 1/2 in. ID. See Fig. 4.

Ventilate the Air Exhaust

![]() WARNING

WARNING

Improper handling of hazardous fluids or inhaling their vapors can cause serious bodily injury, even death. For your safety, it is imperative that you read all product warning labels and Material Safety Data Sheets (MSDS) for the fluids you are using. An MSDS can be obtained from your fluid suppliers. It is also important that you read and understand the warnings and precautions regarding HAZARDOUS FLUID HAZARD on page 5 before you operate.

All systems using hazardous fluid in enclosed areas or within buildings should have a properly designed and installed ventilation system. Consult your local building code and other industrial and governmental standards for proper design criteria.

N

T

|

|

| L |

|

| D C | G |

|

| P | |

|

|

| |

| K |

|

|

| C |

|

|

| A | B |

|

KEY | K |

| |

A | Air line filter | Main air line | |

B | Air line lubricator | L | Ground wire |

C | M | Intake manifold | |

D | Air regulator | N | Glutton pump |

E | Fluid drain valve | P | Grounded air line |

F | Fluid filter | R | Fluid supply |

G | Pump air inlet | S | Fluid suction hose |

H | Grounded fluid line | T | Runaway valve |

JOutlet manifold

J F H

M

![]() E

E

S

R

Fig. 4 | 02323 |

|

307843 9