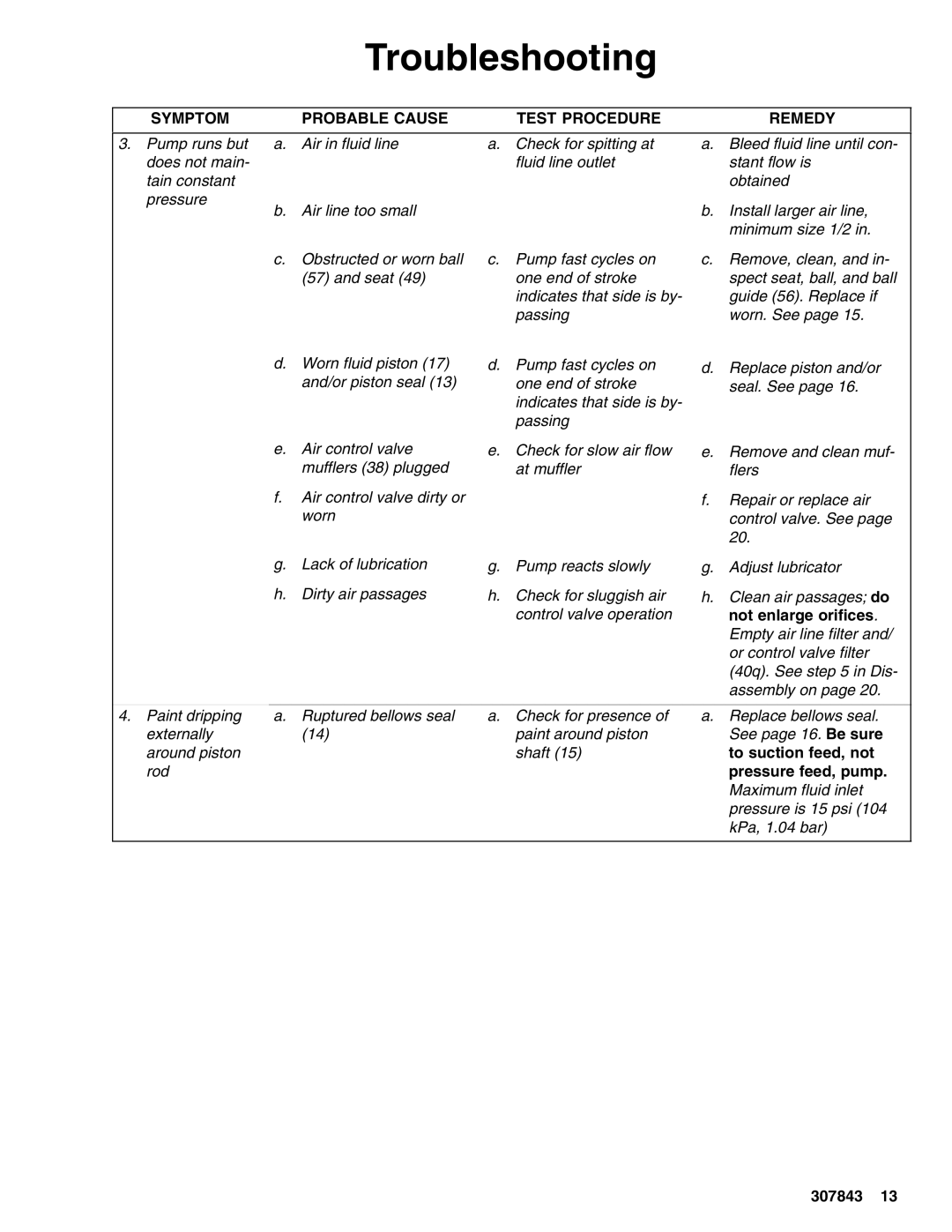

Troubleshooting

SYMPTOM | PROBABLE CAUSE | TEST PROCEDURE | REMEDY |

3. Pump runs but | a. | Air in fluid line |

does not main- |

|

|

tain constant |

|

|

pressure | b. | Air line too small |

| ||

| c. | Obstructed or worn ball |

|

| (57) and seat (49) |

| d. | Worn fluid piston (17) |

|

| and/or piston seal (13) |

a.Check for spitting at fluid line outlet

c.Pump fast cycles on one end of stroke indicates that side is by- passing

d.Pump fast cycles on one end of stroke indicates that side is by- passing

a.Bleed fluid line until con- stant flow is

obtained

b.Install larger air line, minimum size 1/2 in.

c.Remove, clean, and in- spect seat, ball, and ball guide (56). Replace if worn. See page 15.

d.Replace piston and/or seal. See page 16.

e.Air control valve mufflers (38) plugged

f.Air control valve dirty or worn

e.Check for slow air flow at muffler

e.Remove and clean muf- flers

f.Repair or replace air control valve. See page 20.

g. | Lack of lubrication | g. | Pump reacts slowly |

h. | Dirty air passages | h. | Check for sluggish air |

|

|

| control valve operation |

g.Adjust lubricator

h.Clean air passages; do not enlarge orifices. Empty air line filter and/ or control valve filter (40q). See step 5 in Dis- assembly on page 20.

4. Paint dripping | a. Ruptured bellows seal | a. Check for presence of |

externally | (14) | paint around piston |

around piston |

| shaft (15) |

rod |

|

|

a.Replace bellows seal. See page 16. Be sure to suction feed, not pressure feed, pump. Maximum fluid inlet pressure is 15 psi (104 kPa, 1.04 bar)

307843 13