PREVENTIVE MAINTENANCE

A t least twice dailyand durine any lenethy: interruption of sprayinq, with material pressure relieved: remove and clean gun spray t i p and t i p filter in clean solvent of a type recommended by manufacturer~. of the material beine_ smayed. . .Blow

~~~

parts dry with air pressure. Also k e r s e gun nozzle in clean solvent during shutdown periods.

SHUTDOWN PROCEDURE

To maintain efficient operationof unit, t h i s shutdown procedure a t t h ecompletion of each day's spraying must be diligently followed:

1. Shut o f f a i r t opump by closing pump

Handle is a t r i g h t a n g l e petcocko body when closed.

2.Relieve material pressure inpump, hose and spray gun by opening drump valve of

filter cartridgeor screen, if used. Close drain valve.

type | 3 . |

| gun. | spray t i p and f i l t e r , if | used, | |||||

|

| Remove |

| |||||||

i'rom |

| spray |

|

| Immerse in | cleanrecornended | ||||

|

| solvent and | wash thoroughly with a fine | |||||||

bristled | brush. | Using the | air blower valve | |||||||

airmanifold | blov | |||||||||

a i r | through | t i p |

| from front | to back and through | |||||

open end | of | filter. | Refer to Fig.1. Keep | |||||||

spray gun | forward end submerged in && re- | |||||||||

cotmuended type.. | solvent | until | readyto start | |||||||

spraying | again. NOTE: | Do not remove the swaq | ||||||||

e m | from dispensine hose unless the unitis t o be | |||||||||

completely flushed. Keeping unit fully charged | ||||||||||

with material will | minimize~thenecessity for | |||||||||

flushing u n i t .

m:Water based paints w i l l requke a

,final flushing with solventDAILY and also O i l i n g of all externalmoving pump p a r t s to prevent the rusting of the wetted parts. To completely flush unit follow the procedure outlined in subsequent paragraph entitled FLUSHINC UNIT.

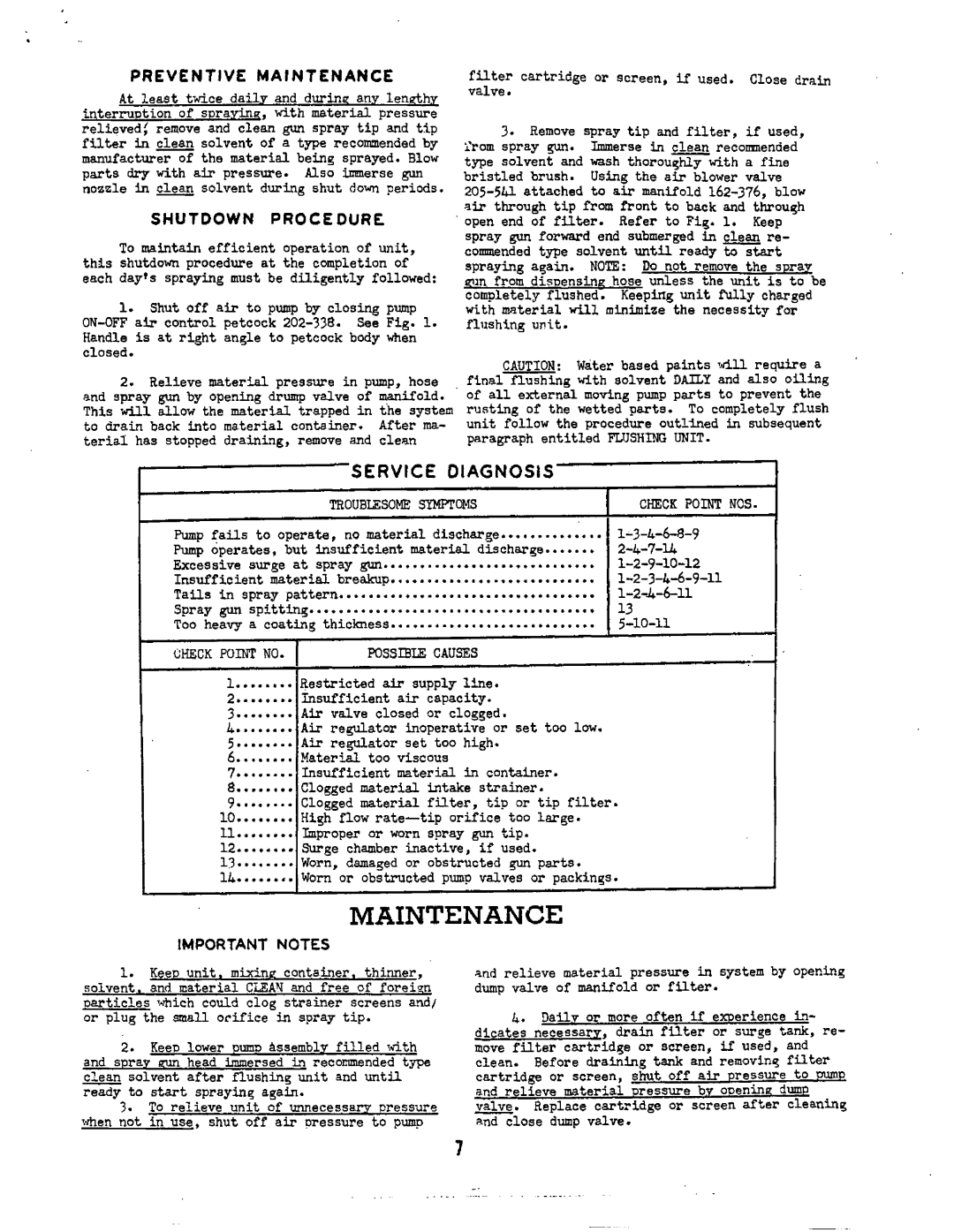

-SERVICE DIAGNOSIS

TROUBLESOME sIMPpOM.5

Fump fails to operate, no material discharge | |||

Pump operates, but insufficient material discharge | |||

Insufficient material breakup | |||

Excessive surge at spray | gun | .................................................... | |

Tails | in spray pattern | ||

Spray | gun spitting |

| .......................... |

Too heavy a coating thic.ess | ............................ | ||

CHECK POINT NOS.

5-10-11

CHECK POINT NO. |

| mssmm CAUSES |

| - | |||

l. |

| Restricted ak. supply line. |

| ||||

2 | Insufficient | air | capacity. |

| |||

3. |

| Air | valve closed or clogged. | toolow. | |||

L |

| A i r | regulator | inoperative | or set | ||

5 |

| A i r | regllator | set toohigh. |

| ||

6 | Material too | viscous |

|

| |||

7 |

| Insufficient material in container. | |||||

e |

| Clogged materid | intake | strainer . | |||

lo9 |

| Clogged material | filter, | tipor | t i p f i l t e r . | ||

| Hish flow | ||||||

ll |

| Improper or worn | spray gun tip . |

| |||

12 |

| Surge chamber inactive, if used. | parts. | ||||

l? |

| Worn, damaged | or | obstructed gun | |||

U | ,. |

|

|

|

|

| |

|

| Worn or obstructed pump valves or packings. | |||||

MAINTENANCE

IMPORTANT NOTES

1. Keev unit, mixine container. thinner, solvent. and material CLEAV and free of foreisn particles rbichcould clog strainer screens andl o r plug the small orificein spray tip.

2. Keep | lower vump | |

and smav mn head immersed | in recommended type | |

clean solvent | after f l u s h i n 4 | unit and u n t i l |

ready tostart sprayine again.

-3. TO reliive - unit Of unnecessary pressure when not in use, shutoff air pressure topump

7

and relieve material pressure in system by opening dump valve of manifold or f i l t e r .

4.Daily or ,more often if experience in- dicates necessar d r a i n f i l t e r or surge tank, re- more filter cart:idne or screen. if used, and

~ and close dump valve.

. . . . . ... . . . . . . . . . . . . . .