Check Valves

![]() Before disassembling, press on ball (26c) to test check valve for proper movement and spring action.

Before disassembling, press on ball (26c) to test check valve for proper movement and spring action.

1. Follow Pressure Relief Procedure, page 15.

2. Remove fluid manifold (M). Leave air connected.

Clean Fluid Manifold, page 20.

M

TI2543A

3. Flush gun to remove residual A and B compo-

nents, page 20. Follow Pressure Relief Proce- dure, page 15.

4. Disconnect air.

TI2540A

CAUTION

To prevent

Repair

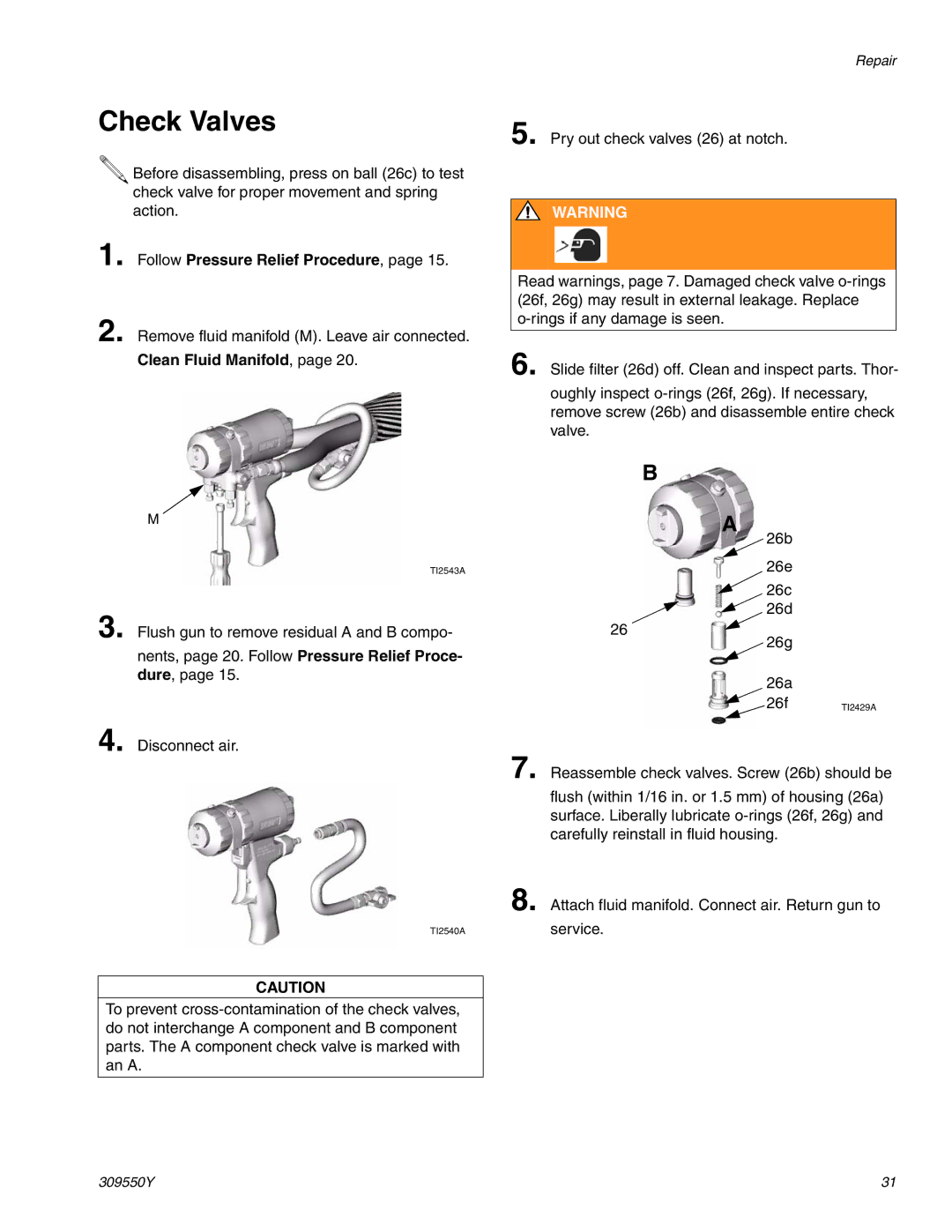

5. Pry out check valves (26) at notch.

![]() WARNING

WARNING

Read warnings, page 7. Damaged check valve

6. Slide filter (26d) off. Clean and inspect parts. Thor-

oughly inspect

B

A

26b

26e

26c

26d

26

26g

26a

26f TI2429A

7. Reassemble check valves. Screw (26b) should be

flush (within 1/16 in. or 1.5 mm) of housing (26a) surface. Liberally lubricate

8. Attach fluid manifold. Connect air. Return gun to

service.

309550Y | 31 |