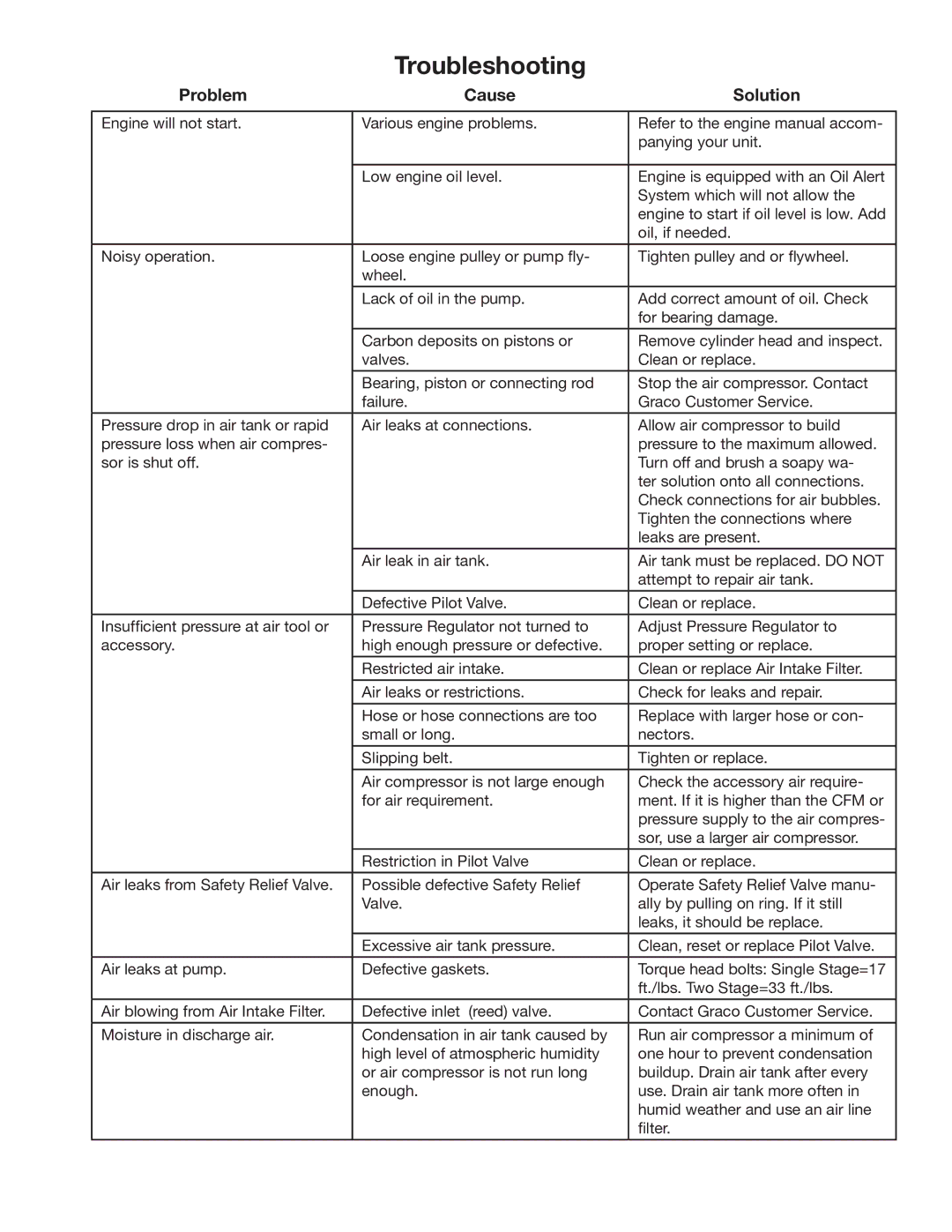

Troubleshooting

Problem | Cause | Solution |

|

|

|

Engine will not start. | Various engine problems. | Refer to the engine manual accom- |

|

| panying your unit. |

|

|

|

| Low engine oil level. | Engine is equipped with an Oil Alert |

|

| System which will not allow the |

|

| engine to start if oil level is low. Add |

|

| oil, if needed. |

|

|

|

Noisy operation. | Loose engine pulley or pump fly- | Tighten pulley and or flywheel. |

| wheel. |

|

|

|

|

| Lack of oil in the pump. | Add correct amount of oil. Check |

|

| for bearing damage. |

|

|

|

| Carbon deposits on pistons or | Remove cylinder head and inspect. |

| valves. | Clean or replace. |

|

|

|

| Bearing, piston or connecting rod | Stop the air compressor. Contact |

| failure. | Graco Customer Service. |

Pressure drop in air tank or rapid | Air leaks at connections. | Allow air compressor to build |

pressure loss when air compres- |

| pressure to the maximum allowed. |

sor is shut off. |

| Turn off and brush a soapy wa- |

|

| ter solution onto all connections. |

|

| Check connections for air bubbles. |

|

| Tighten the connections where |

|

| leaks are present. |

|

|

|

| Air leak in air tank. | Air tank must be replaced. DO NOT |

|

| attempt to repair air tank. |

|

|

|

| Defective Pilot Valve. | Clean or replace. |

|

|

|

Insufficient pressure at air tool or | Pressure Regulator not turned to | Adjust Pressure Regulator to |

accessory. | high enough pressure or defective. | proper setting or replace. |

|

|

|

| Restricted air intake. | Clean or replace Air Intake Filter. |

|

|

|

| Air leaks or restrictions. | Check for leaks and repair. |

|

|

|

| Hose or hose connections are too | Replace with larger hose or con- |

| small or long. | nectors. |

|

|

|

| Slipping belt. | Tighten or replace. |

|

|

|

| Air compressor is not large enough | Check the accessory air require- |

| for air requirement. | ment. If it is higher than the CFM or |

|

| pressure supply to the air compres- |

|

| sor, use a larger air compressor. |

|

|

|

| Restriction in Pilot Valve | Clean or replace. |

|

|

|

Air leaks from Safety Relief Valve. | Possible defective Safety Relief | Operate Safety Relief Valve manu- |

| Valve. | ally by pulling on ring. If it still |

|

| leaks, it should be replace. |

| Excessive air tank pressure. | Clean, reset or replace Pilot Valve. |

|

|

|

Air leaks at pump. | Defective gaskets. | Torque head bolts: Single Stage=17 |

|

| ft./lbs. Two Stage=33 ft./lbs. |

|

|

|

Air blowing from Air Intake Filter. | Defective inlet (reed) valve. | Contact Graco Customer Service. |

|

|

|

Moisture in discharge air. | Condensation in air tank caused by | Run air compressor a minimum of |

| high level of atmospheric humidity | one hour to prevent condensation |

| or air compressor is not run long | buildup. Drain air tank after every |

| enough. | use. Drain air tank more often in |

|

| humid weather and use an air line |

|

| filter. |

|

|

|