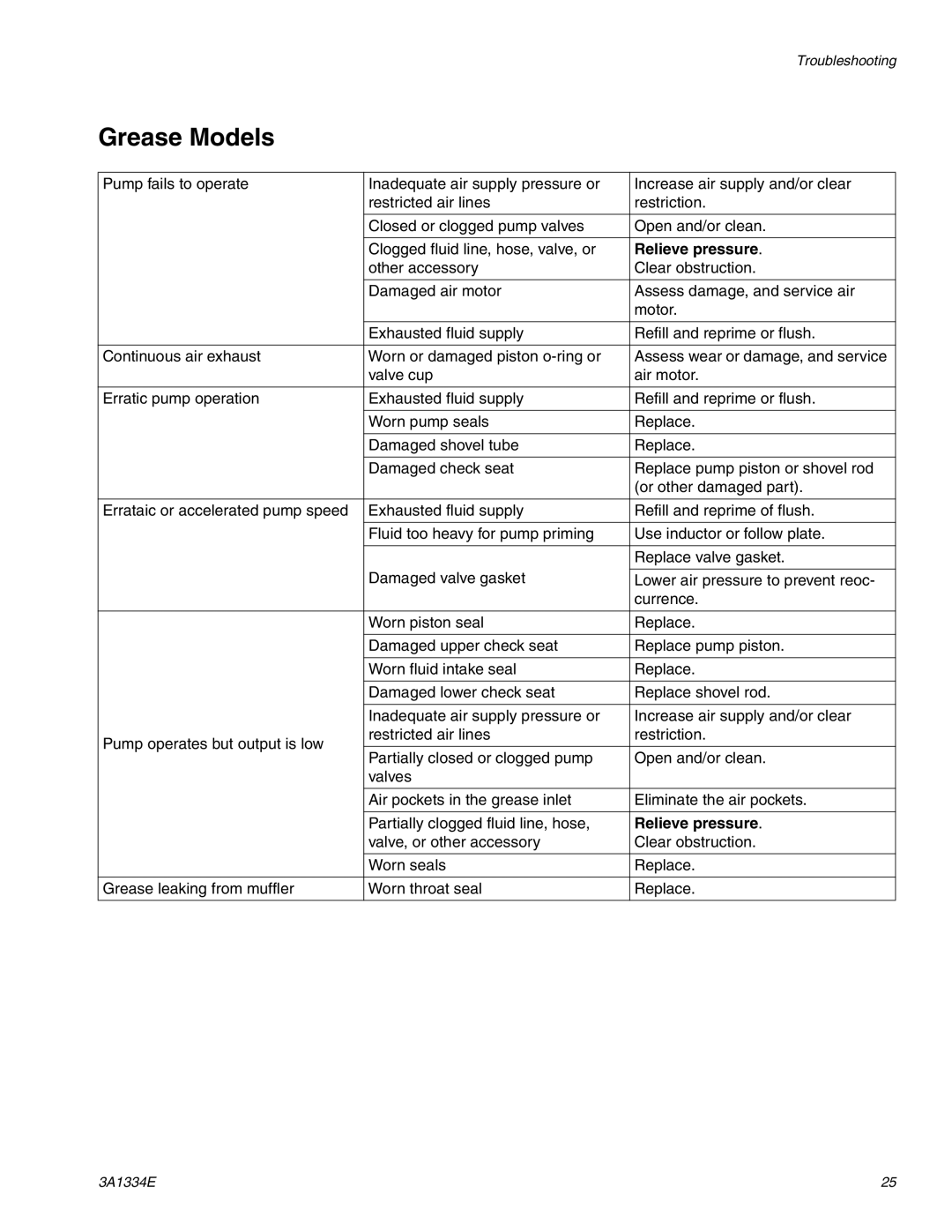

Troubleshooting

Grease Models

Pump fails to operate | Inadequate air supply pressure or | Increase air supply and/or clear | |

| restricted air lines | restriction. | |

|

|

| |

| Closed or clogged pump valves | Open and/or clean. | |

|

|

| |

| Clogged fluid line, hose, valve, or | Relieve pressure. | |

| other accessory | Clear obstruction. | |

|

|

| |

| Damaged air motor | Assess damage, and service air | |

|

| motor. | |

|

|

| |

| Exhausted fluid supply | Refill and reprime or flush. | |

|

|

| |

Continuous air exhaust | Worn or damaged piston | Assess wear or damage, and service | |

| valve cup | air motor. | |

|

|

| |

Erratic pump operation | Exhausted fluid supply | Refill and reprime or flush. | |

|

|

| |

| Worn pump seals | Replace. | |

|

|

| |

| Damaged shovel tube | Replace. | |

|

|

| |

| Damaged check seat | Replace pump piston or shovel rod | |

|

| (or other damaged part). | |

|

|

| |

Errataic or accelerated pump speed | Exhausted fluid supply | Refill and reprime of flush. | |

|

|

| |

| Fluid too heavy for pump priming | Use inductor or follow plate. | |

|

|

| |

|

| Replace valve gasket. | |

| Damaged valve gasket |

| |

| Lower air pressure to prevent reoc- | ||

|

| currence. | |

|

|

| |

| Worn piston seal | Replace. | |

|

|

| |

| Damaged upper check seat | Replace pump piston. | |

|

|

| |

| Worn fluid intake seal | Replace. | |

|

|

| |

| Damaged lower check seat | Replace shovel rod. | |

|

|

| |

| Inadequate air supply pressure or | Increase air supply and/or clear | |

Pump operates but output is low | restricted air lines | restriction. | |

|

| ||

Partially closed or clogged pump | Open and/or clean. | ||

| |||

| valves |

| |

|

|

| |

| Air pockets in the grease inlet | Eliminate the air pockets. | |

|

|

| |

| Partially clogged fluid line, hose, | Relieve pressure. | |

| valve, or other accessory | Clear obstruction. | |

|

|

| |

| Worn seals | Replace. | |

|

|

| |

Grease leaking from muffler | Worn throat seal | Replace. | |

|

|

|

3A1334E | 25 |