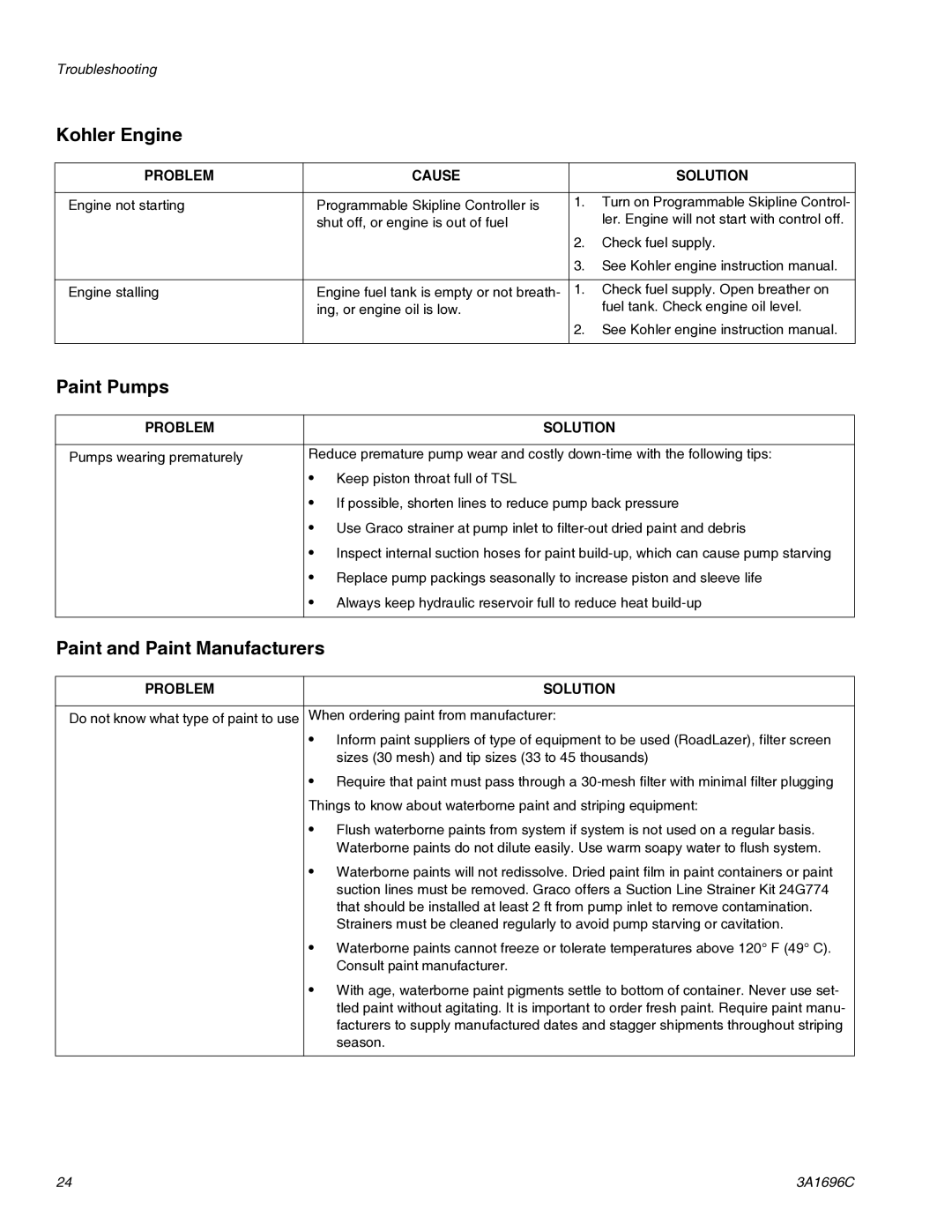

Troubleshooting

Kohler Engine

PROBLEM | CAUSE |

| SOLUTION |

|

|

|

|

Engine not starting | Programmable Skipline Controller is | 1. | Turn on Programmable Skipline Control- |

| shut off, or engine is out of fuel |

| ler. Engine will not start with control off. |

|

| 2. | Check fuel supply. |

|

| 3. | See Kohler engine instruction manual. |

|

|

|

|

Engine stalling | Engine fuel tank is empty or not breath- | 1. | Check fuel supply. Open breather on |

| ing, or engine oil is low. |

| fuel tank. Check engine oil level. |

|

| 2. | See Kohler engine instruction manual. |

|

|

|

|

Paint Pumps

PROBLEM | SOLUTION |

|

|

Pumps wearing prematurely | Reduce premature pump wear and costly |

| • Keep piston throat full of TSL |

| • If possible, shorten lines to reduce pump back pressure |

| • Use Graco strainer at pump inlet to |

| • Inspect internal suction hoses for paint |

| • Replace pump packings seasonally to increase piston and sleeve life |

| • Always keep hydraulic reservoir full to reduce heat |

|

|

Paint and Paint Manufacturers

PROBLEM | SOLUTION |

|

|

Do not know what type of paint to use | When ordering paint from manufacturer: |

| • Inform paint suppliers of type of equipment to be used (RoadLazer), filter screen |

| sizes (30 mesh) and tip sizes (33 to 45 thousands) |

| • Require that paint must pass through a |

| Things to know about waterborne paint and striping equipment: |

| • Flush waterborne paints from system if system is not used on a regular basis. |

| Waterborne paints do not dilute easily. Use warm soapy water to flush system. |

| • Waterborne paints will not redissolve. Dried paint film in paint containers or paint |

| suction lines must be removed. Graco offers a Suction Line Strainer Kit 24G774 |

| that should be installed at least 2 ft from pump inlet to remove contamination. |

| Strainers must be cleaned regularly to avoid pump starving or cavitation. |

| • Waterborne paints cannot freeze or tolerate temperatures above 120° F (49° C). |

| Consult paint manufacturer. |

| • With age, waterborne paint pigments settle to bottom of container. Never use set- |

| tled paint without agitating. It is important to order fresh paint. Require paint manu- |

| facturers to supply manufactured dates and stagger shipments throughout striping |

| season. |

|

|

24 | 3A1696C |